A kind of fast-curing water-based epoxy concrete repair coating and preparation method thereof

A water-based epoxy, fast-curing technology, applied in the field of coatings, can solve problems such as increased cost and hidden safety hazards in construction, and achieve the effects of fast curing speed, excellent adhesion, and improved stability and appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 waterborne epoxy resin emulsion

[0030] Weigh 60 g of E-51 epoxy resin, 6 g of environmentally friendly diluent and L-446 g of propylene glycol block polyether surfactant, mix well, heat to 75°C, add 80 g of deionized water at 2500 r / min rotation speed, Disperse for 20min to obtain a water-based epoxy resin emulsion, wherein the environmentally friendly diluent is prepared by mixing 5g of allyl glycidyl ether and 1g of epoxy-terminated silicone oil.

Embodiment 2-4 and

[0037] The preparation of embodiment 2-4 and comparative example 3-5 water-based epoxy concrete repair paint

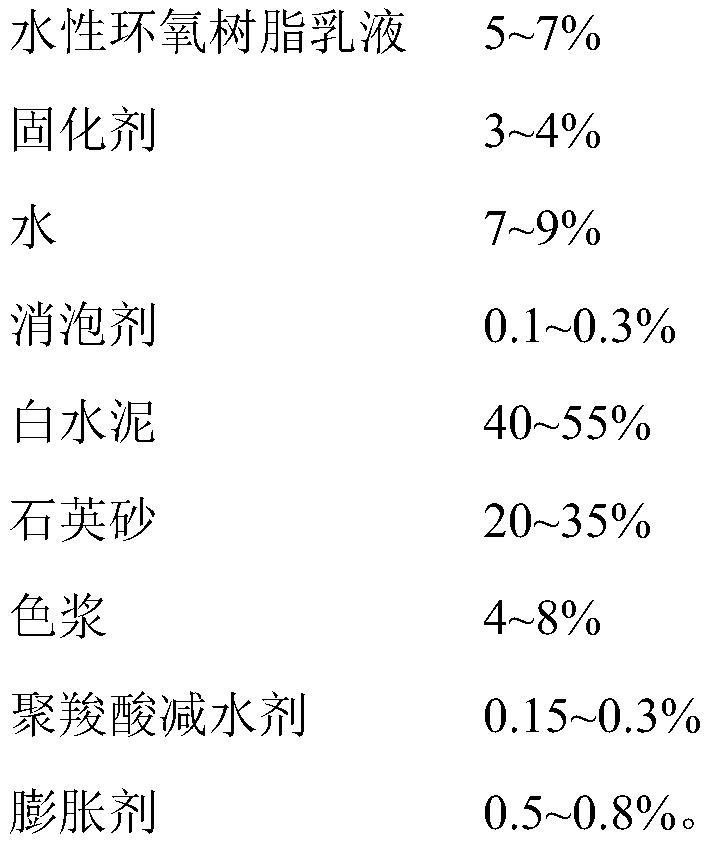

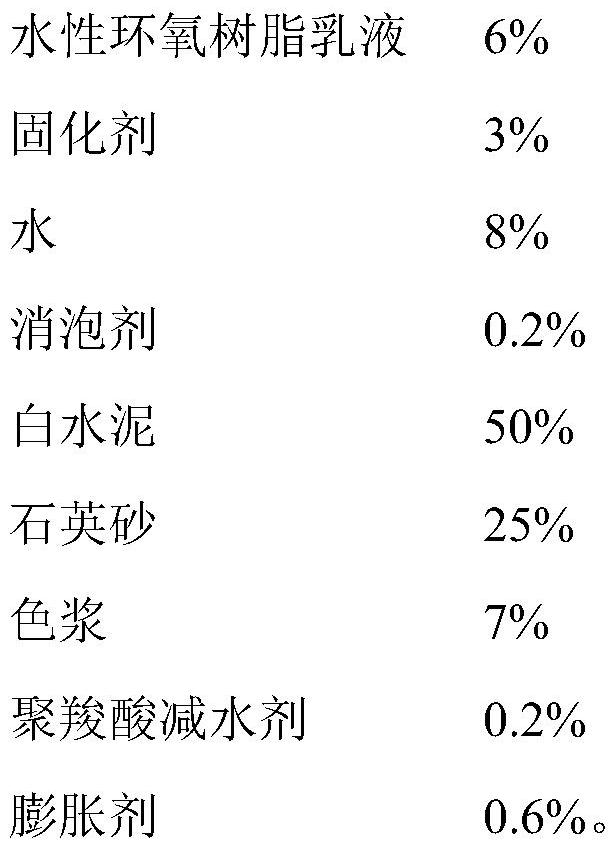

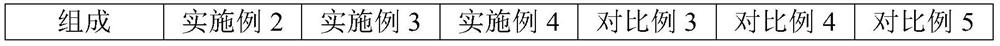

[0038] The preparation raw material composition of embodiment 2-4 and comparative example 3-5 water-based epoxy concrete repair paint is shown in table 1 below:

[0039] Table 1 The raw material composition of each group of water-based epoxy concrete repair coatings

[0040]

[0041]

Embodiment 2

[0043] The preparation of embodiment 2 water-based epoxy concrete repair paint:

[0044] Weigh white cement and quartz sand, add them into a stirring pot, stir at a speed of 40r / min for 2min, then add water, water-based epoxy resin emulsion, triethylenetetramine, defoamer, polycarboxylate water reducer and swelling agent The water-based epoxy concrete repair coating can be obtained by stirring at a speed of 60r / min for 80min, and finally adding the color paste and stirring at a speed of 40-50r / min for 4-6min.

[0045] Examples 3-4 and Comparative Examples 3-5 refer to Example 2 for the preparation of waterborne epoxy concrete repair paints.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com