Breeding method for lowering bacterial quantity and heavy metal content in bodies of bivalve molluscs

A breeding method and technology of bivalve mollusks, applied in chemical instruments and methods, fish farming, special treatment targets, etc., can solve the problems of reducing the number of bacteria in oysters, and achieve the effect of meat quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

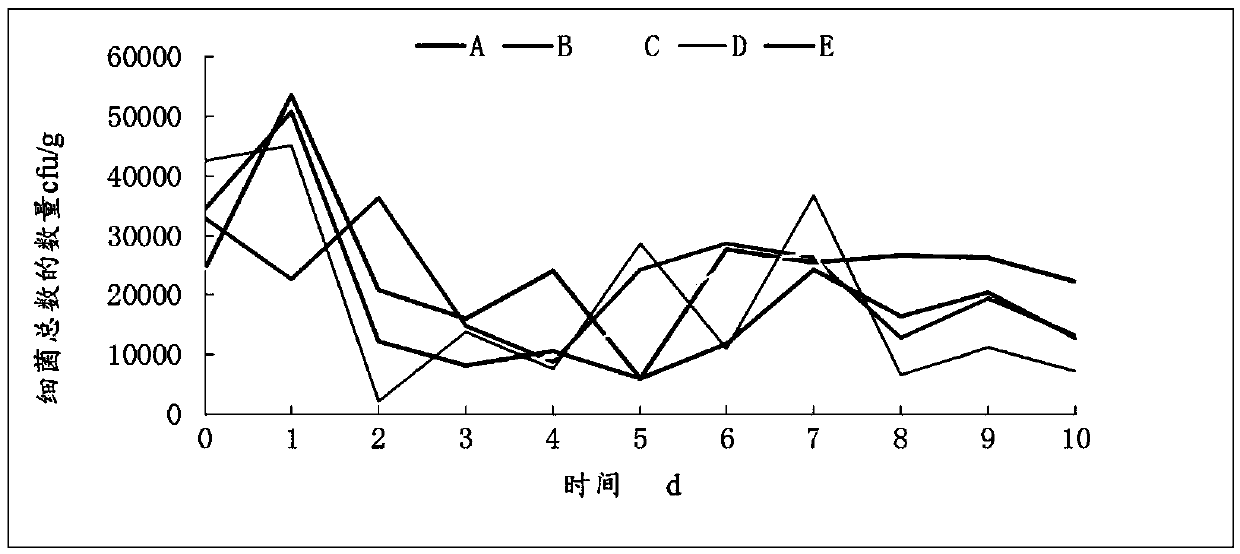

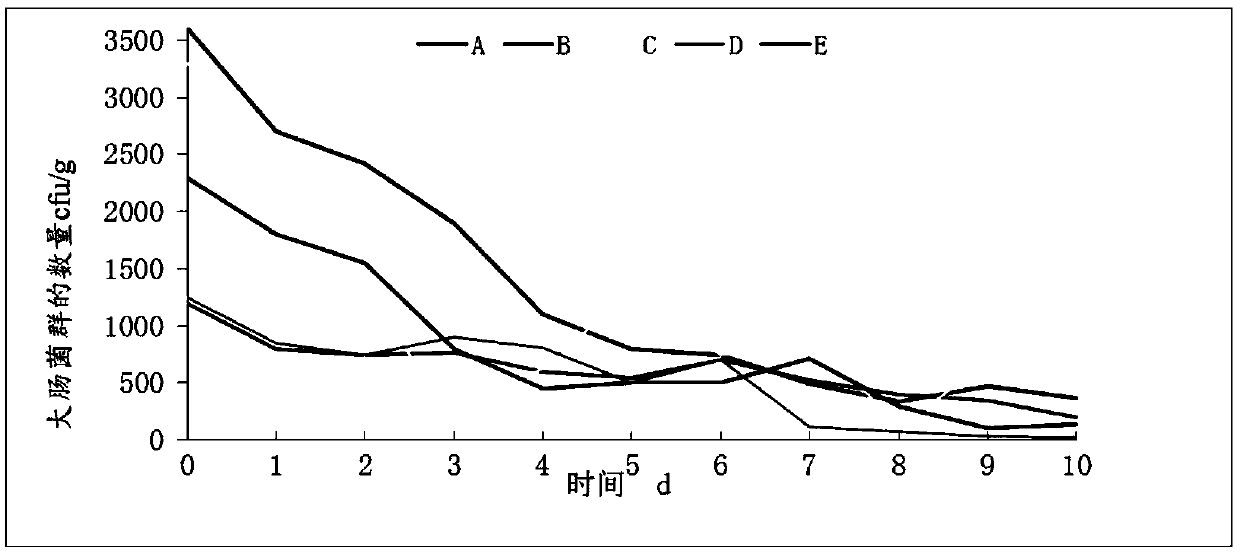

[0048] For specifications 2×25m 2 After the indoor cement pool is disinfected, the seawater that has passed through the sand filter and the net filter in turn is added to 1.8m, and the seawater is disinfected with 1350g of 50% strong chlorine essence for 12h, and then neutralized with 675g of sodium thiosulfate, continuously Aerate for 12 hours, and wait for the residual chlorine in the water to disappear completely to obtain dechlorinated seawater. Introduce dechlorinated seawater to 0.5m through screen filtration 3 In the PVC barrels, the introduction of seawater in each barrel is 0.3m 3 , hang 2 net cages in each bucket, and fill 20 polluted oysters in each net cage. The five treatment groups are A, B, C, D, and E; the PVC barrels of groups A, B, and C were introduced with dechlorinated seawater, and the PVC barrels of groups D and E were introduced with non-chlorinated seawater; group A replaced non-chlorinated seawater every day For seawater, group B was replaced with ...

Embodiment 2

[0052] The specification is 1.5×25m 2 After the indoor cement pool is disinfected, add the seawater that has passed through the sand filter and net filter to 0.8m, and disinfect the water body with 600g of strong chlorine essence with 50% available chlorine for 12 hours, and then neutralize it with 300g of sodium thiosulfate, and continuously expose Gas for 12 hours, until all residual chlorine in the water disappears, and dechlorinated seawater is obtained. The dechlorinated seawater is introduced into 15 0.5m 3 In the PVC barrels, the amount of disinfected seawater introduced in each barrel is 0.3m 3 , hang 2 net cages in each bucket, fill 20 polluted oysters in each net cage, change the breeding water body every day. The salinity of the 5 treatment groups were 10‰, 15‰, 20‰, 25‰ and 30‰, respectively, and the salinity of 20‰ was used as the control group, and each treatment set up 3 parallels. It was carried out under natural light and room temperature, the pH of seawate...

Embodiment 3

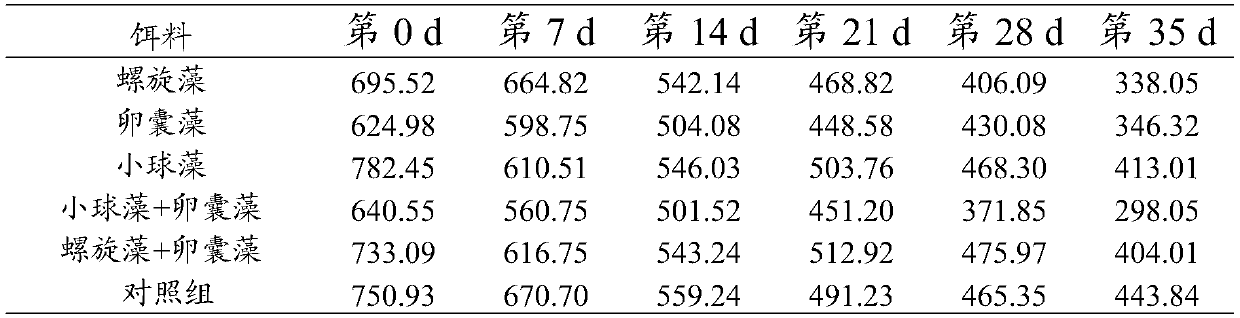

[0061] For specifications 1.8×25m 2 After the indoor cement pool is disinfected, add the seawater that has passed through the sand filter and screen filter to 1.5m, and disinfect the water body with 1125g of 50% strong chlorine essence for 12 hours, and then neutralize it with 562.5g of sodium thiosulfate. Aerate for 12 hours, and wait for the residual chlorine in the water to disappear completely to obtain dechlorinated seawater. The dechlorinated seawater is introduced into 18 0.6m 3 In the PVC barrels, the amount of dechlorinated seawater introduced in each barrel is 0.4m 3 , hang 2 net cages in each bucket, fill 20 polluted oysters in each net cage, change the breeding water body every day. The diets of the 5 treatment groups were Spirulina, Oocyst, Chlorella, Chlorella + Oocyst, Spirulina + Oocyst, the control group was not fed any bait, and three parallels were set up for each treatment. It was carried out under natural light and room temperature, the pH of seawater w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com