Thin coal seam coal mining machine rocker arm

A coal mining machine and thin coal seam technology, applied in the direction of earthwork drilling, slitting machinery, driving devices, etc., can solve the problems of good coal loading effect, reduce the height of the drum blades, increase the connection size of the drum, etc., to achieve lifting coal loading effect, reduction of impact load, effect of reduction in thickness of the rocker arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

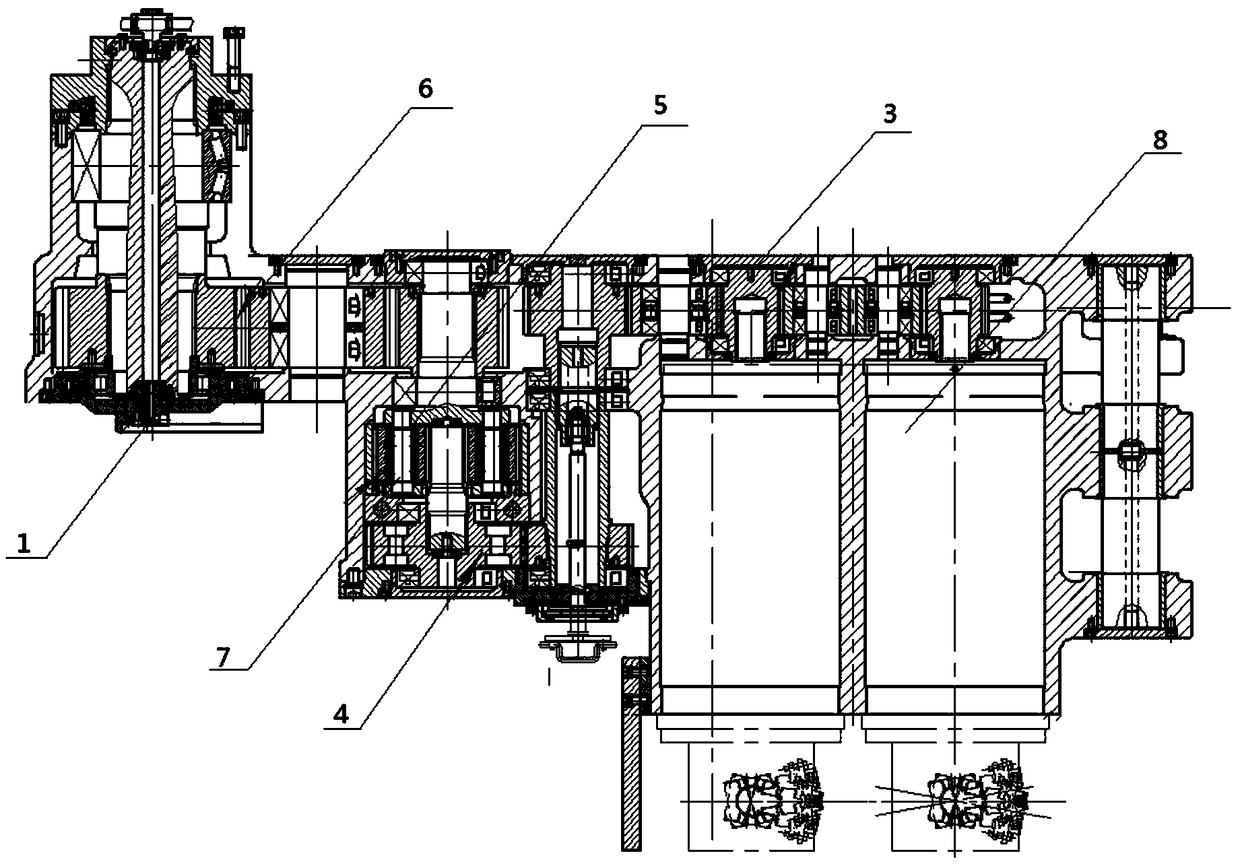

[0015] A rocker arm of a thin coal seam shearer, comprising a rocker arm main body 1 and a shock absorbing module 2, the inner right end of the rocker arm body 1 is provided with a first spur gear transmission 3, and the first stage spur gear transmission 3 is sequentially Connect the second-stage spur gear transmission 4, the third-stage planetary reduction transmission 5 and the fourth-stage spur gear transmission 6.

[0016] The planetary reducer 7 is arranged in the third-stage transmission position, away from the vibration source of the drum, and the final stage adopts a spur gear output structure, which improves the impact resistance and reduces the diameter of the output shaft of the drum.

[0017] The rocker main body 1 is mainly driven by a small-diameter double rocker motor 8 .

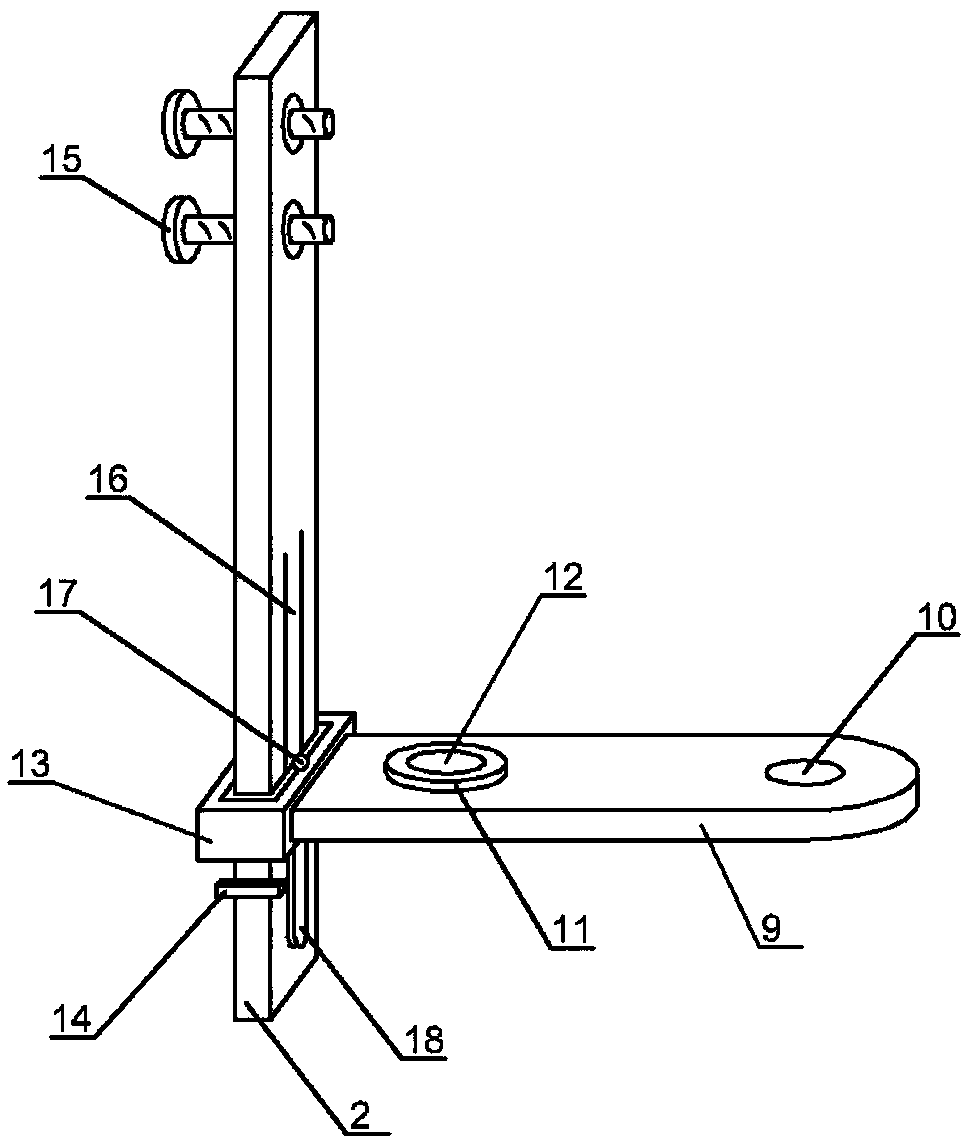

[0018] The lower ends of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com