Preparation method of self-repairing degradable C3N4/subject-object film

A C3N4, host-guest technology, used in nanostructure manufacturing, nanotechnology, coating and other directions, can solve problems such as no reports, achieve good self-healing effect, wide application prospects, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of self-healing degradable C of the present invention 3 N 4 The preparation method of host-guest film comprises the steps:

[0027] Step 1, carbon nitride (C 3 N 4 ) powder was added to the branched polyethyleneimine (PEI-βCD) solution of β-cyclodextrin, ultrasonically oscillated, and centrifuged to obtain the branched polyethyleneimine (C 3 N 4 - PEI-βCD) solution;

[0028] Step 2, the C obtained in step 1 3 N 4 -PEI-βCD solution is self-assembled on the surface of the substrate as the first layer, and then the PAA-AD solution is self-assembled as the second layer. After repeating several cycles, a PAA-AD / C is prepared 3 N 4 -PEI-βCD self-healing degradable host-guest film.

Embodiment 1

[0030] 1) 1mg carbon nitride (C 3 N 4 ) powder was added branched polyethyleneimine (PEI-βCD) of 4mg / mLβ-cyclodextrin, ultrasonic vibration 60min, centrifugation speed 3500rpm, centrifugation time 5min, obtained clear milky white carbon nitride-β-cyclodextrin branched Polyethyleneimine (C 3 N 4 - PEI-βCD) solution.

[0031] 2) Soak the cleaned glass piece in 4mg / mLLC 3 N 4 -PEI-βCD solution for 15min, rinse with water to remove the physically adsorbed polymer; then soak in 4mg / mL PAA-AD solution for 15min and rinse with water; repeat the above steps for 30 cycles to obtain PAA-AD / C 3 N 4 -PEI-βCD self-healing degradable host-guest film.

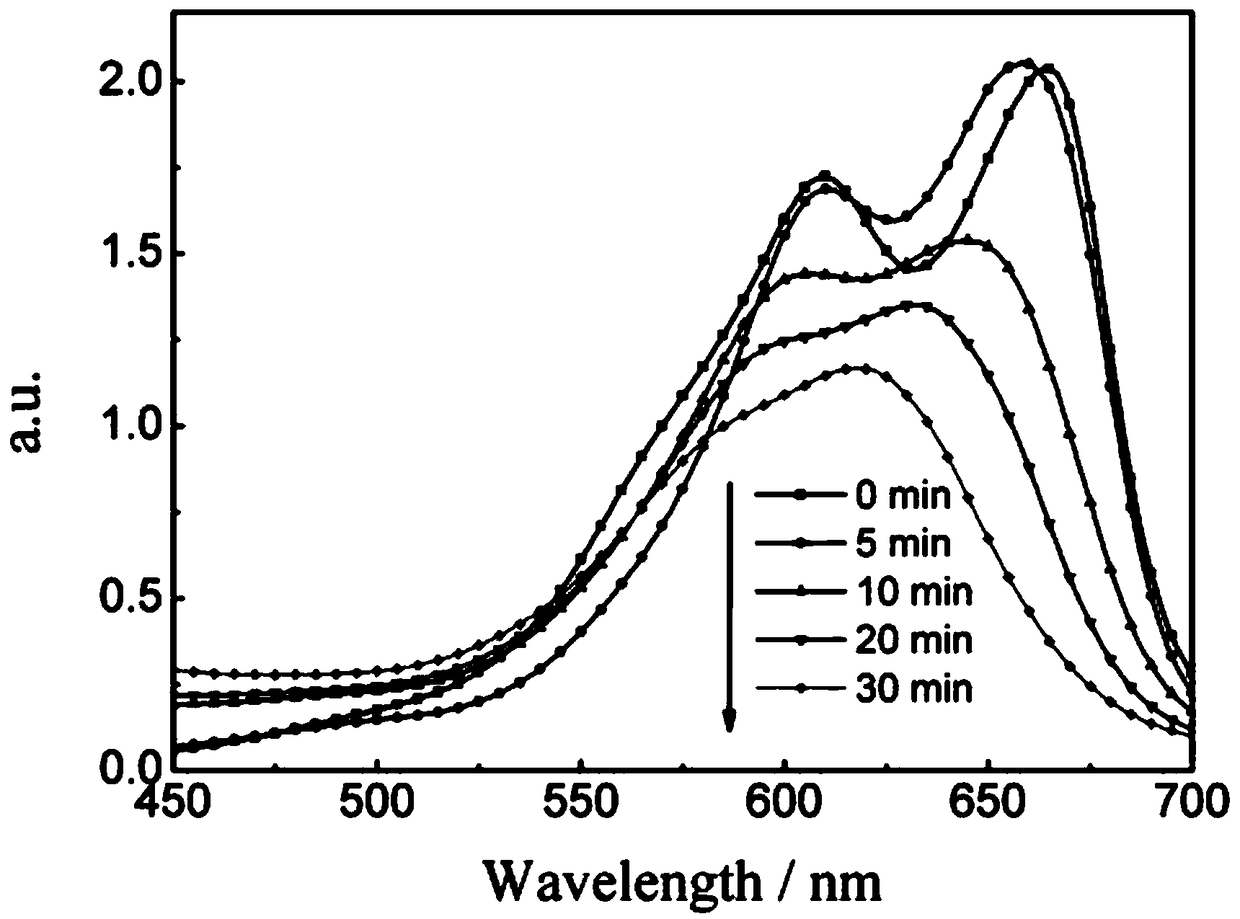

[0032] figure 1 It is that embodiment 1 prepares PAA-AD / C 3 N 4 - UV absorption curve of PEI-βCD self-healing degradable host-guest film for degradation of methylene blue.

[0033] figure 2 It is that embodiment 1 prepares PAA-AD / C 3 N 4 -Physical diagram of the degradation of methylene blue by PEI-βCD self-healing degradable hos...

Embodiment 2

[0036] 1) 2mg carbon nitride (C 3 N 4 ) powder was added branched polyethyleneimine (PEI-βCD) of 5mg / mLβ-cyclodextrin, ultrasonic vibration 80min, centrifugation speed 4000rpm, centrifugation time 7min, obtained clear milky white carbon nitride-β-cyclodextrin branched Polyethyleneimine (C 3 N 4 - PEI-βCD) solution.

[0037] 2) Soak the cleaned glass piece in 5mg / mLLC 3 N 4 -PEI-βCD solution for 20min, rinse with water to remove the physically adsorbed polymer; then soak in 5mg / mL PAA-AD solution for 20min and then rinse with water; repeat the above steps for 25 cycles to obtain PAA-AD / C 3 N 4 -PEI-βCD self-healing degradable host-guest film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com