Soft porcelain material with visible light reflecting properties and method for preparing soft porcelain material

A technology with reflective performance and visible light, applied in the field of building wall materials, can solve the problems of poor reflective performance of soft porcelain decorative materials, affecting the service life of soft porcelain materials, and cumbersome preparation process, so as to reduce the possibility of photochemical reaction, water repellency and air permeability. Strong and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In addition, the present invention also provides a method for preparing the soft porcelain material with visible light reflection performance, which specifically includes the following steps:

[0045] 1) Weigh each component of the formulation amount, add the required polymer emulsion, cellulose, deionized water, coupling agent and leveling agent into the reaction kettle under normal temperature and pressure, and use a high-speed disperser to Stir at a speed of 300-600rpm / min until viscous, then add inorganic fillers, light-reflecting pigments, and dispersants in sequence, and disperse at a high speed at a speed of 1200-1500rpm / min to obtain a mixture;

[0046]2) At a stirring speed of 400-700rpm / min, add a wetting agent and an antifoaming agent to the mixture prepared in step 1), and mix thoroughly to obtain the soft porcelain material with visible light reflection properties.

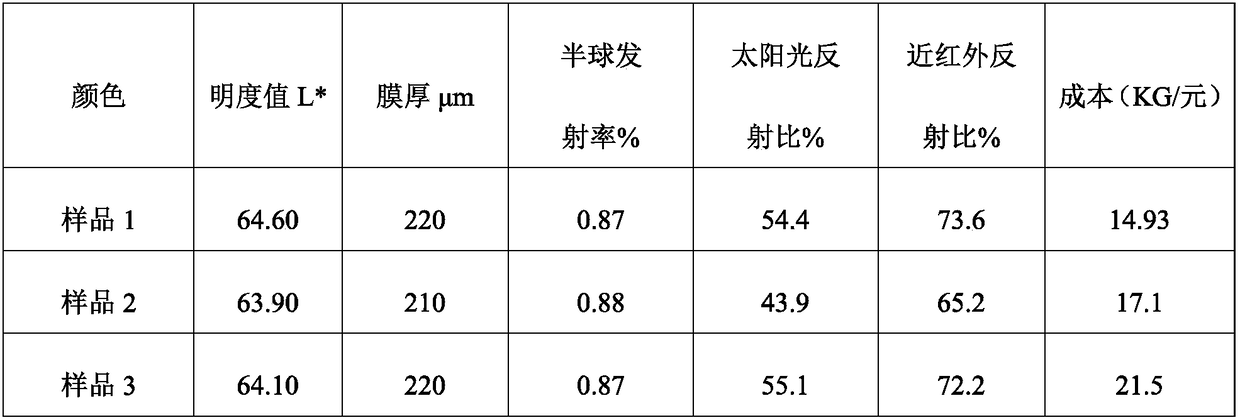

Embodiment 1

[0048] A soft porcelain material with visible light reflection performance, comprising the following raw materials in parts by mass: 25 parts of polymer emulsion, 20 parts of inorganic filler, 0.5 part of wetting agent, 0.5 part of defoaming agent, 1 part of coupling agent, fiber 0.1 parts of pigment, 1 part of leveling agent, 10 parts of light reflective pigment, 5 parts of dispersant, 20 parts of deionized water.

[0049] As an improvement, the polymer emulsion adopts acrylic emulsion, and the solid content in the acrylic emulsion is 35%.

[0050] As an improvement, heavy calcium carbonate is used as the inorganic filler. The wetting agent adopts sulfonated oil.

[0051] As an improvement, the defoamer uses emulsified silicone oil. As an improvement, the coupling agent is a silane coupling agent; the leveling agent is polydimethylsiloxane.

[0052] As an improvement, the cellulose is hydroxyethyl cellulose.

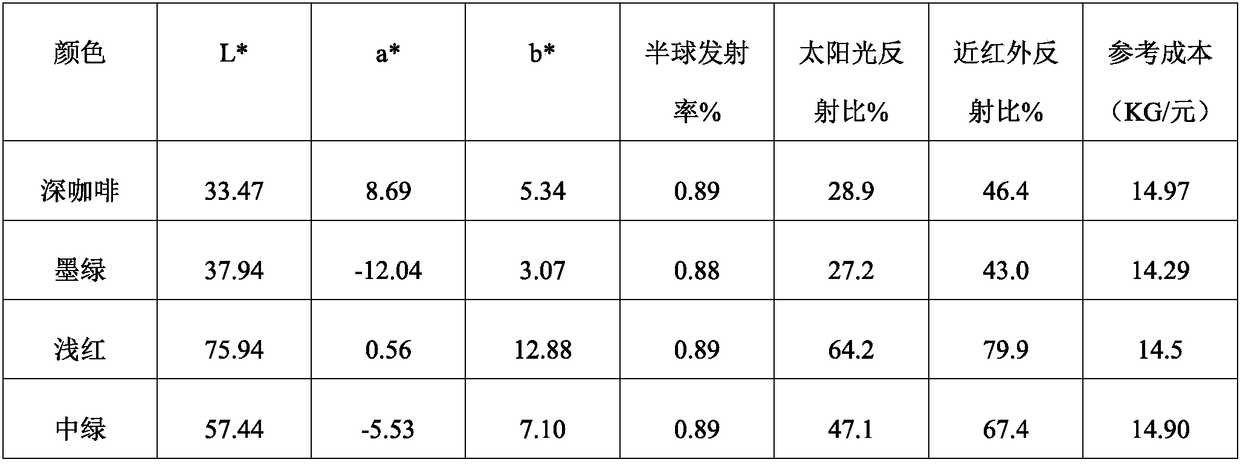

[0053] As an improvement, the light reflective pigment include...

Embodiment 2

[0059] A soft porcelain material with visible light reflection performance, comprising the following raw materials in parts by mass: 50 parts of polymer emulsion, 45 parts of inorganic filler, 1 part of wetting agent, 1 part of defoaming agent, 5 parts of coupling agent, fiber 0.3 parts of pigment, 5 parts of leveling agent, 30 parts of light reflective pigment, 10 parts of dispersant, 40 parts of deionized water.

[0060] As an improvement, the polymer emulsion adopts acrylic emulsion, and the solid content in the acrylic emulsion is 55%.

[0061] As an improvement, quartz sand is used as the inorganic filler. As an improvement, the wetting agent uses mercaptan compounds.

[0062] As an improvement, the defoamer uses polydimethylsiloxane.

[0063] As an improvement, the coupling agent is a silane coupling agent; the leveling agent is polydimethylsiloxane.

[0064] As an improvement, ethyl-2-hydroxyethyl cellulose is used as the cellulose.

[0065] As an improvement, Altir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com