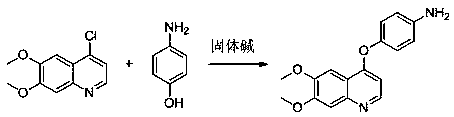

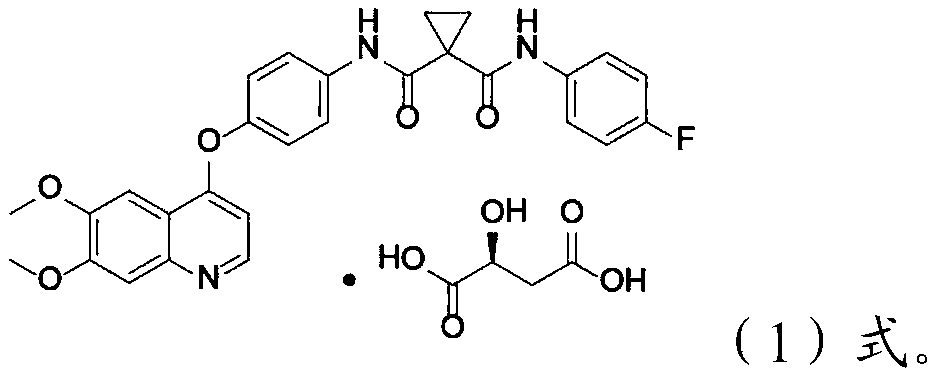

Method for preparing antitumor drug cabozantinib intermediate by solid base catalysis

A solid base and oxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as containing, and achieve the effects of reducing production costs and high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

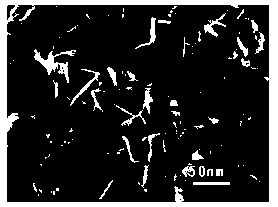

[0050] Prepare the Mg / Al composite metal oxide solid base of Zr doping as follows:

[0051] 1) dissolving zirconium nitrate pentahydrate (20mmol), magnesium nitrate hexahydrate (60mmol) and aluminum nitrate hexahydrate (20mmol) in water to form a nitrate mixture;

[0052] 2) Prepare 2mol / L sodium hydroxide dissolved in water to obtain an alkaline solution;

[0053] 3) Raise the temperature of the nitrate mixture to 60-70°C, keep the speed at 800rpm, and then use the DMD15-13 peristaltic pump (Langer Constant Flow Pump Co., Ltd.) to drop the alkaline mixture to keep the pH of the nitrate system at 8.5 Between -9.5, heat preservation and stirring for 16-18h, then centrifuge, wash the filter cake with deionized water until the filtrate becomes neutral, and then dry at 75-80°C to constant weight to obtain a Zr-doped Mg / Al composite metal hydroxide solid base precursor;

[0054] 4) The Mg / Al composite metal hydroxide solid alkali precursor of Zr doping is placed in saturated pota...

Embodiment 1-A

[0064] Adopt single factor variable method to study the influence of Zr doping on solid base catalytic performance: compare with the preparation method of sequence 5 in the table 1 of embodiment 1, do not add zirconium nitrate pentahydrate in step 1), all the other are LDO in the embodiment 1 The preparation method of -300 is exactly the same; the prepared solid base is named LDO-300-A.

Embodiment 1-B

[0066] Adopt single factor variable method to study the impact of potassium carbonate replacement on solid base catalytic performance: compare with the preparation method of sequence 5 in the table 1 of embodiment 1, do not carry out the processing of step 4), all the other are the same as that of LDO-300 in the embodiment 1 The preparation method is exactly the same; the prepared solid base is named LDO-300-B.

[0067] Replace LDO-300 in Example 1 with LDO-300-A and LDO-300-B respectively, and catalyze 4-chloro-6,7-dimethoxyquinoline and 4-aminophenol according to the preparation method in Example 1 reaction, wherein the conversion rate of the LDO-300-A catalytic system is 67.2%, and the conversion rate of the LDO-300-B catalytic system is 72.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com