Fluorescent glaze, ceramic product prepared from same and method for preparing ceramic product

A glaze and fluorescence technology, which is applied in the field of ceramic decoration, can solve the problems of low chemical stability and thermal stability of fluorescent glaze, achieve high chemical performance and thermal stability, stable chemical performance and thermal stability, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

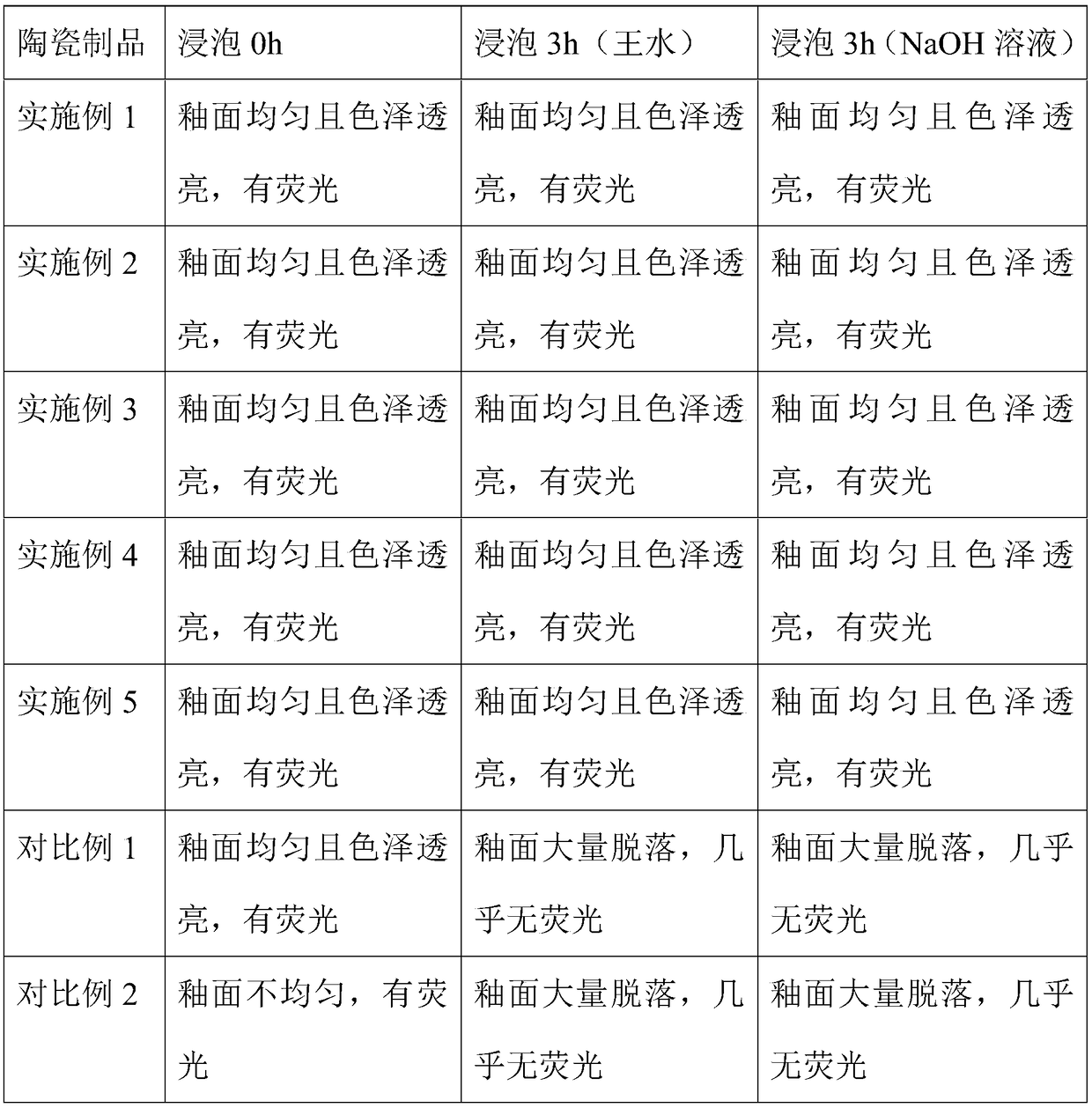

Examples

Embodiment 1

[0025] This embodiment 1 provides a fluorescent glaze, the raw materials of which include, by weight, 70 parts of long-lasting phosphor powder; 40 parts of borax; 3 parts of glass powder; and 0.8 part of zinc oxide. The preparation method of the fluorescent ceramic product made from the fluorescent glaze is as follows:

[0026] (1) Mix the components of the raw materials evenly, mix them in the ratio of material: ball: water = 1:2:0.8, put them in a ball mill for ball milling for 8 hours, add water to the mixture after ball milling to make a glaze slurry, and age for 3 hours , get fluorescent glaze;

[0027] (2) Coating the above-mentioned fluorescent glaze on the surface of a non-glazed ceramic product, putting it into an electric furnace, calcining at 950° C., and then cooling naturally to obtain the fluorescent ceramic product.

Embodiment 2

[0029] This embodiment 2 provides a fluorescent glaze, and its raw materials include, by weight, 60 parts of long-lasting phosphor powder; 38 parts of borax; 2 parts of glass powder; and 0.5 part of zinc oxide. The preparation method of the fluorescent ceramic product made from the fluorescent glaze is as follows:

[0030] (1) Mix the components of the raw materials evenly, mix them in the ratio of material: ball: water = 1:2:0.8, put them in a ball mill for ball milling for 6 hours, add water to the mixture after ball milling to make a glaze slurry, and age for 4 hours , get fluorescent glaze;

[0031] (2) Coating the above-mentioned fluorescent glaze on the surface of the finished ceramic product without glaze, putting it into an electric furnace for calcination at 900° C., and then cooling naturally to obtain the crude fluorescent ceramic;

[0032] (3) Coating transparent glaze on the surface of the rough fluorescent ceramic product, calcining at 880° C., and then cooling ...

Embodiment 3

[0035] Embodiment 3 provides a fluorescent glaze, and its raw materials include, by weight, 50 parts of long-lasting phosphor powder; 30 parts of borax; 5 parts of glass powder; and 1 part of zinc oxide. The preparation method of the fluorescent ceramic product made from the fluorescent glaze is as follows:

[0036] (1) Mix the components of the raw materials evenly, mix them in the ratio of material: ball: water = 1:2:0.8, put them in a ball mill for ball milling for 4 hours, add water to the mixture after ball milling to make a glaze slurry, and stale for 3.5 hours , get fluorescent glaze;

[0037] (2) Spray the above-mentioned fluorescent glaze on the surface of the glaze-free ceramic product, put it into an electric furnace, calcinate at 900° C., and then cool naturally to obtain the fluorescent ceramic product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com