3D printing method for structured packing for supergravity rotation bed with constant channels

A technology of supergravity rotating bed and structured packing, applied in chemical instruments and methods, manufacturing auxiliary devices, chemical/physical/physical-chemical processes, etc. Convenient and quick maintenance and replacement, convenient manufacturing and installation, and the effect of enhancing the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

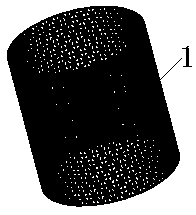

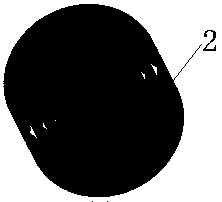

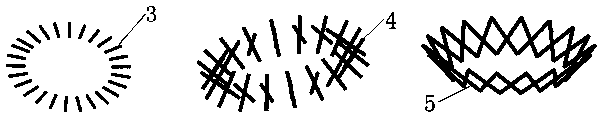

[0046] The present invention provides a 3D printing method for structured packing used in a high-gravity rotating bed with a constant channel. First, a three-dimensional modeling software is used to construct a screen structure with central symmetry, and then a wire mesh of the packing is constructed at equal distances along the radial direction. structure; then three kinds of interference structures are used in the radial direction to form a support unit with central symmetry, and each unit is staggered by 0-10° and installed in sequence along the axial direction to form the main body of the support structure; finally, the main body of the support structure and the wire mesh The structures are assembled together to form a three-dimensional model of structured packing for a high-gravity rotating bed with central symmetry and constant liquid and gas channels; after the three-dimensional model of the packing is completed, a solid model is manufactured using 3D printing technology....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com