Arc-shaped round steel processing tooling

A technology of arc and round steel, which is applied in the field of arc-shaped round steel processing tooling, and can solve the problems of low machining accuracy and high difficulty in processing arc-shaped round steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

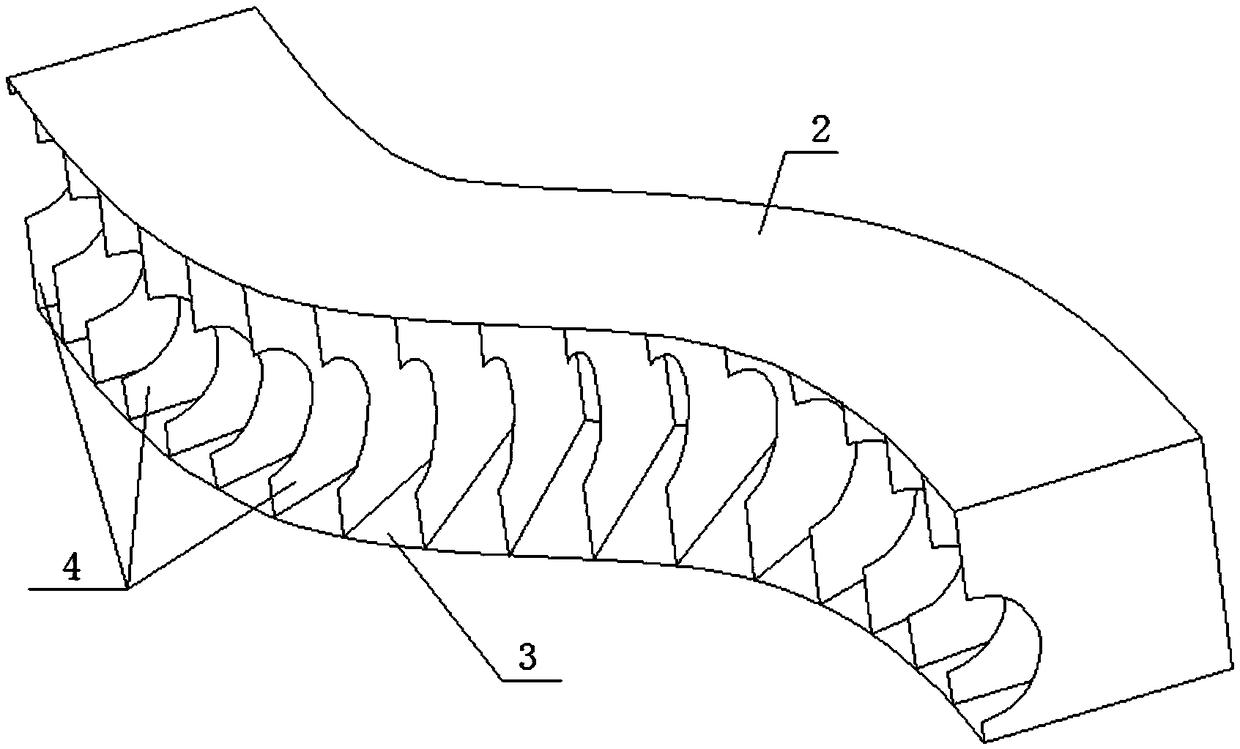

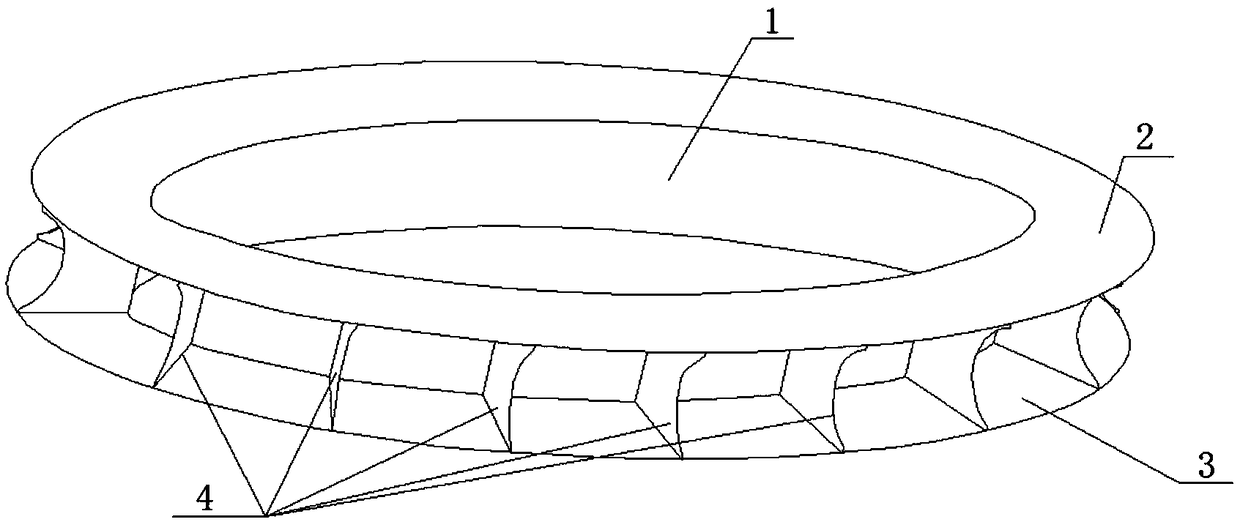

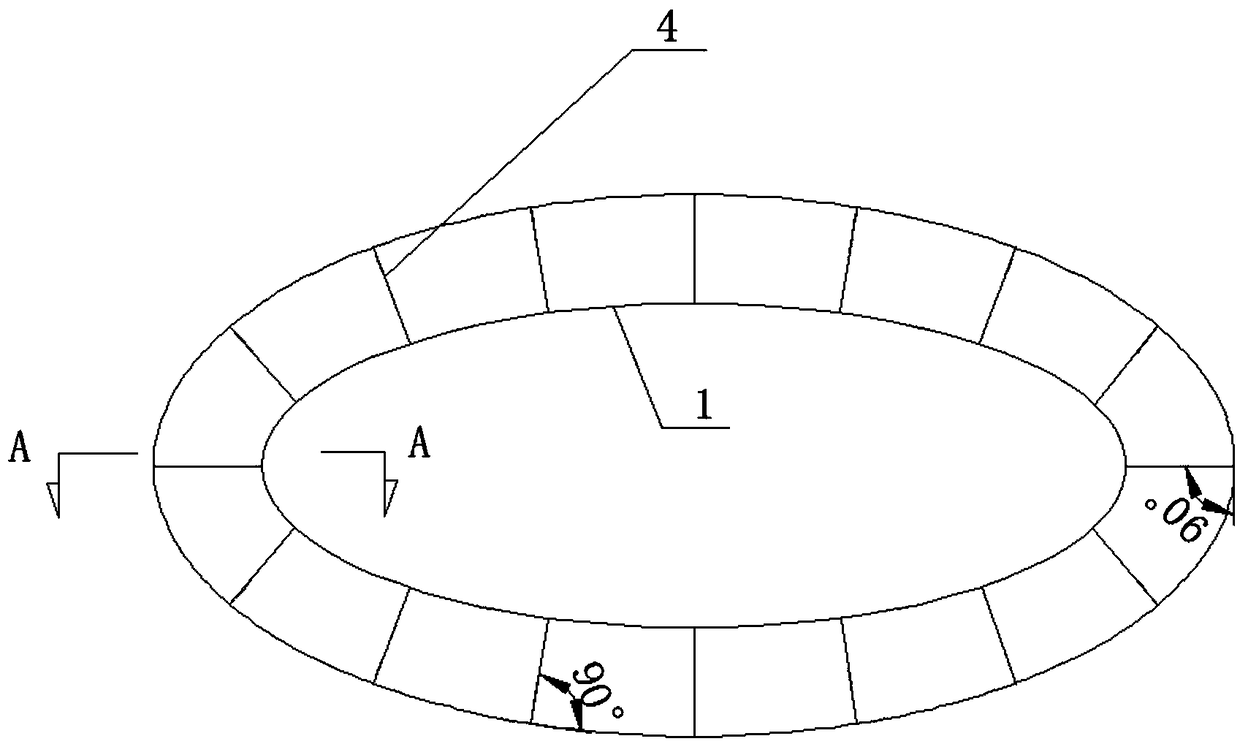

[0025] Such as Figure 1-3 As shown, a kind of arc-shaped round steel processing tooling provided by this embodiment includes an arc-shaped back plate 1, the upper end and the lower end of the back plate 1 are respectively connected with a top plate 2 and a bottom plate 3, and the top plate 2 Arranged in alignment with the bottom plate 3, between the top plate 2 and the bottom plate 3 there are a plurality of baffles 4 arranged at intervals, the outer side of the baffles 4 is provided with arc-shaped grooves, the baffles 4 The height is greater than or equal to 2.5 times the radius r of the round steel. Specifically, by setting the arc back plate 1, the arc trend of the back plate 1 is the same as the shape of the arc-shaped round steel to be processed, and by setting a plurality of baffle plates 4 arranged at intervals between the top plate 2 and the bottom plate 3 And arc-shaped grooves are arranged on the outside of the baffle plate 4. Since the plurality of baffle plates ...

Embodiment 2

[0029] Such as Figure 4-7 As shown, it is an arc-shaped round steel processing tool provided by this embodiment. The difference between it and Embodiment 1 is that the arc-shaped round steel processing tool shown is a three-dimensional structure as a whole, and the back plate 1 is in the shape of an "S" The top plate 2 and the bottom plate 3 are arranged on one side of the back plate 1, so as to realize the processing and manufacturing of the three-dimensional "S" shaped round steel. In addition, the overall shape of the curved round steel processing tool shown can also be changed according to the shape of other forms of round steel.

[0030] In addition, other structures in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com