Method and device for purifying poisonous gas through cooperation of magnetic-enhanced electrofiltration dedusting and low-temperature plasmas

A technology of low-temperature plasma and toxic gas, which is applied in the field of dust removal and gas purification, and can solve problems such as the difficulty of effectively removing fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

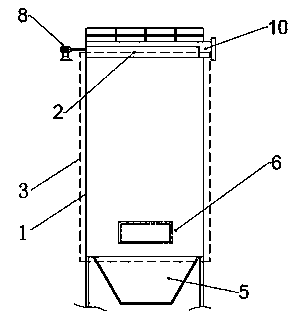

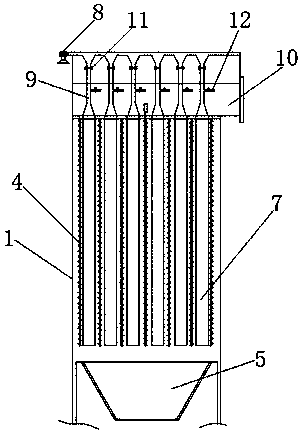

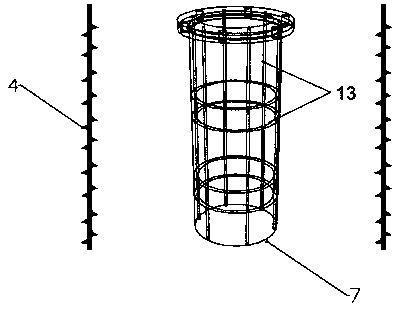

Image

Examples

Embodiment 1

[0033] The concentration of particulate matter in an industrial waste gas is 40 mg / m 3 , SO 2 The concentration is 1200mg / m 3 , NO X The concentration is 500 mg / m 3 , VOCs concentration is 450mg / m 3 .

[0034] The industrial exhaust gas with a humidity of 50% is passed through the corona electrode and the catalyst (TiO 2 – SiO 2 ) in the corona area produced by the coated electric filter cloth (the oxygen concentration in the exhaust gas is 5%), the corona electrode and the electric filter cloth with catalyst coating are connected to an external power supply, and the power supply voltage is 85kV. The corona area is charged, and low-temperature plasma is generated in the corona area at the same time. The charged particles and low-temperature plasma move to the electric filter cloth under the action of the magnetic field force (the magnetic field strength is 60T) and the electric field force, and the particle size is larger than that of the electric filter cloth. Particle...

Embodiment 2

[0040] The concentration of particulate matter in an industrial waste gas is 34 mg / m 3 , SO 2 The concentration is 1600mg / m 3 , NO X The concentration is 650 mg / m 3 .

[0041] The industrial exhaust gas with a humidity of 80% is passed through the corona electrode and the catalyst (Ag 2 O-Al 2 o 3 ) coated electric filter cloth (the oxygen concentration in the exhaust gas is 10%), the corona electrode and the electric filter cloth with catalyst coating are connected to an external power supply, and the power supply voltage is 35kV. The corona area is charged, and low-temperature plasma is generated in the corona area at the same time. The charged particles and low-temperature plasma move to the electric filter cloth under the action of the magnetic field force (the magnetic field strength is 15T) and the electric field force, and the particle size is larger than that of the electric filter cloth. Particles with a pore size (3 μm) on the filter cloth settle due to the bl...

Embodiment 3

[0047] The concentration of particulate matter in an industrial waste gas is 78 mg / m 3 , SO 2 The concentration is 2000mg / m 3 , NO X The concentration is 860 mg / m 3 , VOCs concentration is 420 mg / m 3 .

[0048] The industrial exhaust gas with a humidity of 40% is passed into the corona area (the oxygen concentration in the exhaust gas is 7%) produced by the corona electrode and the electric filter cloth coated with catalyst (Pd metal) at a flow rate of 10m / s. The electrode and the electric filter cloth with catalyst coating are connected to an external power supply. The power supply voltage is 52kV. At 10°C, the particles in the gas are charged in the corona area, and at the same time low-temperature plasma is generated in the corona area, and the charged particles and low-temperature The plasma moves to the electric filter cloth under the action of magnetic field force (magnetic field strength 40T) and electric field force, and the particles with a particle size larger t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com