Preparation method of grapefruit compound enzyme and product and application thereof

A compound enzyme and pomelo technology, applied in the direction of bacteria, applications, food ingredients, etc. used in food preparation, can solve the problems that restrict the processing of pomelo, and achieve the effect of promoting large-scale industrial planting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

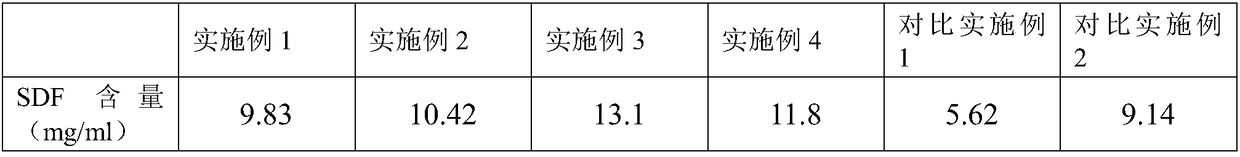

Examples

Embodiment 1

[0027] a. Take 1000g pomelo peel with 1 / 3~1 / 2 thickness of the white sac removed, cut into strips, with a width of 0.1~0.5cm, boil with 10% NaCl and 1% sodium bicarbonate water for 2min, separate the solid and liquid and cool to room temperature, Add 6Kg of water, add 0.85g of pectinase and 1.5g of cellulase to hydrolyze for 90min;

[0028] b. Take 2000g of pomelo meat and 200g of lemon, break them into pieces, add 0.8g of naringinase for enzymolysis, pH 4.0, and enzymolysis for 60min, first coarsely filter and then centrifuge to remove limonin; Pitaya and tomato are pulped, and according to the weight of the pulp, add 10Kg of water, 1260g of sugar, 2.5g of acid protease and 4g of hemicellulase, and enzymatically hydrolyze for 60 minutes; inactivate;

[0029] c. Mix the enzymolyzate obtained in the above steps, and inoculate Streptococcus thermophilus and Lactobacillus sporogenes, wherein the inoculation amount of Streptococcus thermophilus is 10×10 5 cfu / ml, the inoculation ...

Embodiment 2

[0031] a. Take 3000g pomelo peel with 1 / 3~1 / 2 thickness of the white sac removed, cut into strips, width 0.1~0.5cm, boil with 12% NaCl and 1% sodium bicarbonate water for 2min, separate solid and liquid and cool to room temperature, Add 15Kg of water, then add 3g of pectinase and 6g of cellulase to hydrolyze for 90min;

[0032] b. Take 6600g of pomelo meat and 700g of lemon, break them into pieces, add 3g of naringinase for enzymolysis, pH 4.5, enzymolysis for 60min, first coarse filter and then centrifuge to remove limonin; then each 750g of apple, pear, pitaya Pulp fruit and tomato, and according to the weight of the pulp, add 40Kg of water, 5Kg of sugar, 6g of acid protease and 10g of hemicellulase, and enzymatically hydrolyze for 60min; inactivate;

[0033] c. Mix the enzymolyzate obtained in the above steps, and inoculate Streptococcus thermophilus and Lactobacillus sporogenes, wherein the inoculation amount of Streptococcus thermophilus is 10×10 5 cfu / ml, the inoculatio...

Embodiment 3

[0035] a. Take 1000g pomelo peel with 1 / 3~1 / 2 thickness of the white sac removed, cut into strips, with a width of 0.1~0.5cm, boil with 12% NaCl and 2% sodium bicarbonate water for 2min, separate the solid and liquid and cool to room temperature, Add 8Kg of water, add 1g of pectinase and 1.5g of cellulase to hydrolyze for 90min;

[0036] b. Take 2200g of grapefruit meat and 220g of lemon, break them into pieces, add 0.96g of naringinase for enzymolysis, pH4.5, and enzymolysis for 60min, first coarse filter and then centrifuge to remove limonin; Make pulp of dragon fruit and tomato, and add 15Kg of water and 1.5Kg of sugar, 6g of acid protease and 10g of hemicellulase according to the weight of pulp, and hydrolyze for 60 minutes; inactivate;

[0037] c. Mix the enzymolyzate obtained in the above steps, and inoculate Streptococcus thermophilus and Lactobacillus sporogenes, wherein the inoculation amount of Streptococcus thermophilus is 10×10 5 cfu / ml, the inoculation amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com