Penaeus vannamei cultivation system of biomass combined heat and power production

A technology of cogeneration and aquaculture system, which is applied in the field of aquaculture and comprehensive utilization of resources, and can solve the problems of fluctuation of physicochemical and biological indicators of microecological bacteria agent water body, high equipment cost, lack of comprehensive treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

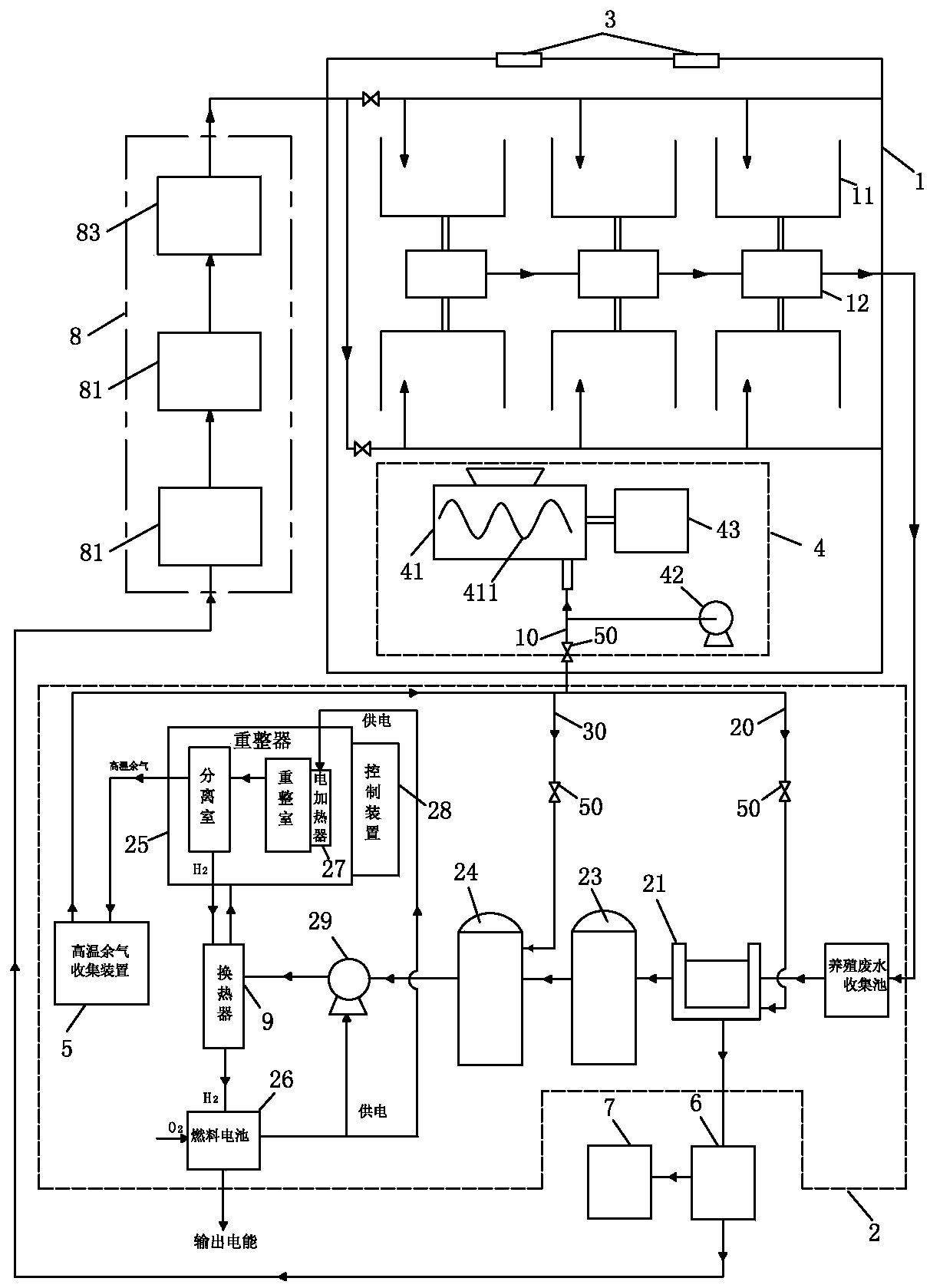

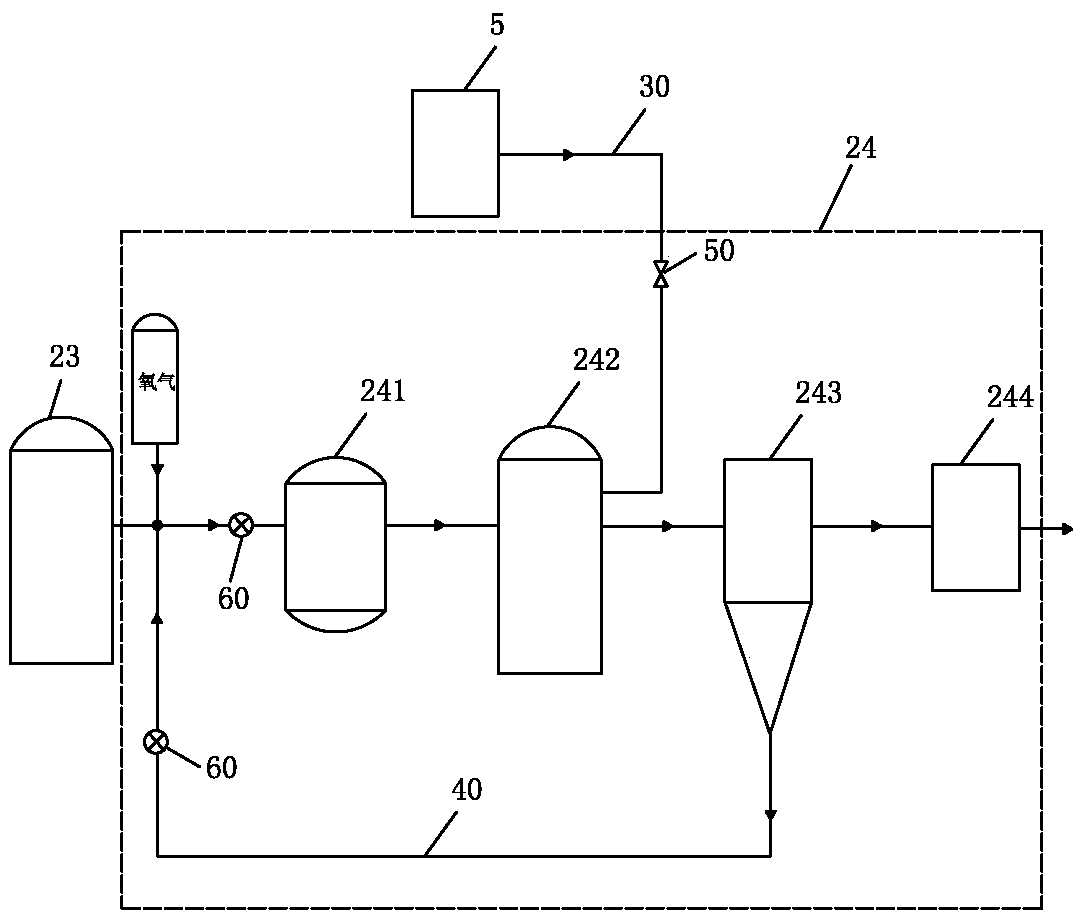

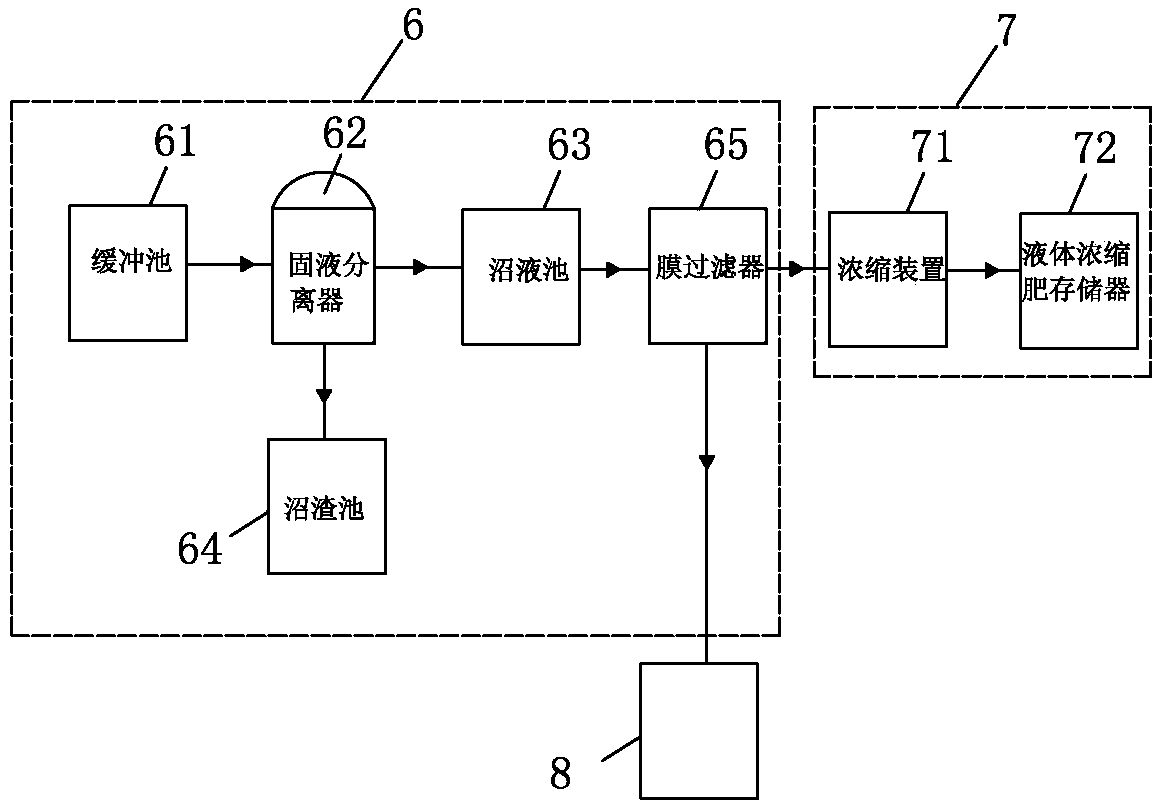

[0036] Penaeus vannamei aquaculture system with biomass combined heat and power, such as figure 1 As shown, it includes a prawn breeding greenhouse 1, an aquaculture wastewater thermal power station 2 arranged around the prawn breeding greenhouse 1, a biogas slurry and biogas residue treatment device 6, an organic fertilizer manufacturing device 7 and a breeding water treatment device 8, and the prawn breeding greenhouse 1 is provided with Lighting device 3, temperature regulator 4 and several groups of cultivation units, each group of cultivation units comprises two cultivation ponds 11 and a drainage pond 12 arranged between the two cultivation ponds 11, the water inlet of drainage pond 12 is connected with the two cultivation ponds The water outlet of 11 communicates by pipeline. The aquaculture wastewater thermal power station 2 includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com