On-line monitoring system of vibration feeder

A technology of vibrating feeder and monitoring system, which is applied in the field of online monitoring system, can solve problems such as inability to monitor, and achieve the effect of improving stable operation efficiency and convenient browsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

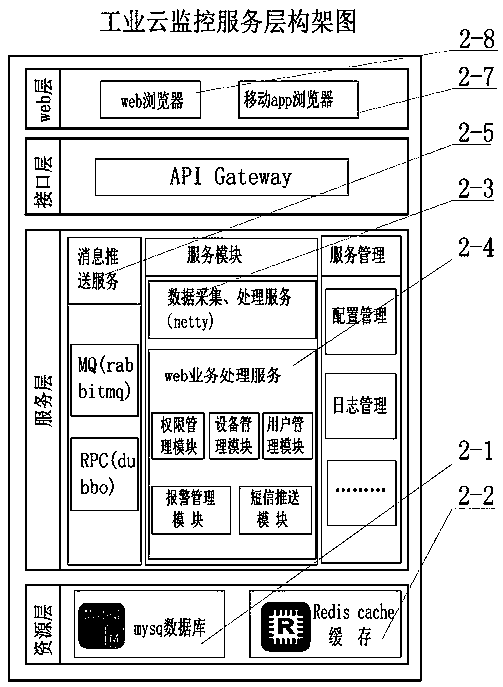

[0016] control Figure 1~2 , the vibrating feeder online monitoring system of the present invention is composed of two parts, the physical perception layer and the industrial cloud monitoring service layer, and is characterized in that: the physical perception layer 1 includes equipment sensors 1-1, downhole data substations 1-2, downhole Data central station 1-3 and ground receiving station 1-4, according to the data to be detected, motor and bearing temperature, rubber spring temperature, vibration frequency, speed, etc., install equipment sensor 1-1 at the corresponding part of the vibrating feeder to collect data , transmit the collected data to the downhole data substation (control cabinet) 1-2 through the wired method, after sorting and processing the data through the PLC controller of the control cabinet, use the cable to transmit to the downhole data central station (master control cabinet) 1-3 , the main control cabinet transmits the data to the ground data receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com