An automatic solution color reaction sensor

A color reaction and sensor technology, applied in the field of sensors, can solve the problems of inability to realize automatic titration measurement, manual maintenance and calibration, short service life, etc., and achieve the effect of improving the price, reducing labor costs, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

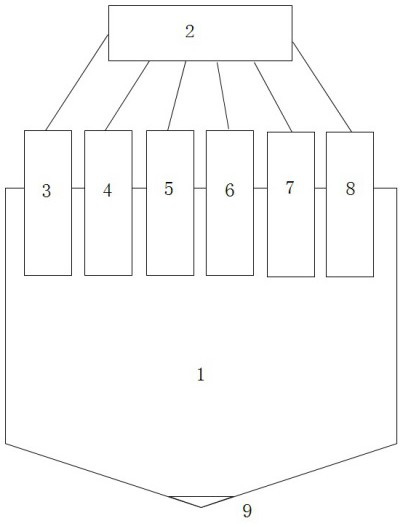

[0023] Such as figure 1 As shown, the present invention designs an automatic solution color reaction sensor, including a measurement tank 1, a measurement control unit 2, a visible light color probe 3, an intake pump 4, an exhaust pump 5, a measurement solution inlet pump 6, and a color reagent inlet pump 8 preferably may also include a cleaning fluid inlet pump 7 .

[0024] Wherein, the measuring tank 1 is a hollow container, which is preferably cast from corrosion-resistant materials. The upper half of the measuring tank is a cylinder, and the lower half is an inverted cone, which is placed upright on a horizontal surface through a support; The top of the tank 1 is provided with installation holes and several through holes, and the bottom of the measuring tank is provided with a drainage and exhaust hole 9 with a check valve. The drain and exhaust hole 9 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com