A device for detecting the bearing capacity of scaffolding

A detection device and a force-bearing technology, which are applied in the measurement device, the use of a stable shear force to test the strength of materials, the test of mechanical parts, etc., can solve problems such as inconvenient measurement, and reduce the probability of separation and stability. Strong, easy-to-measure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described with reference to the accompanying drawings.

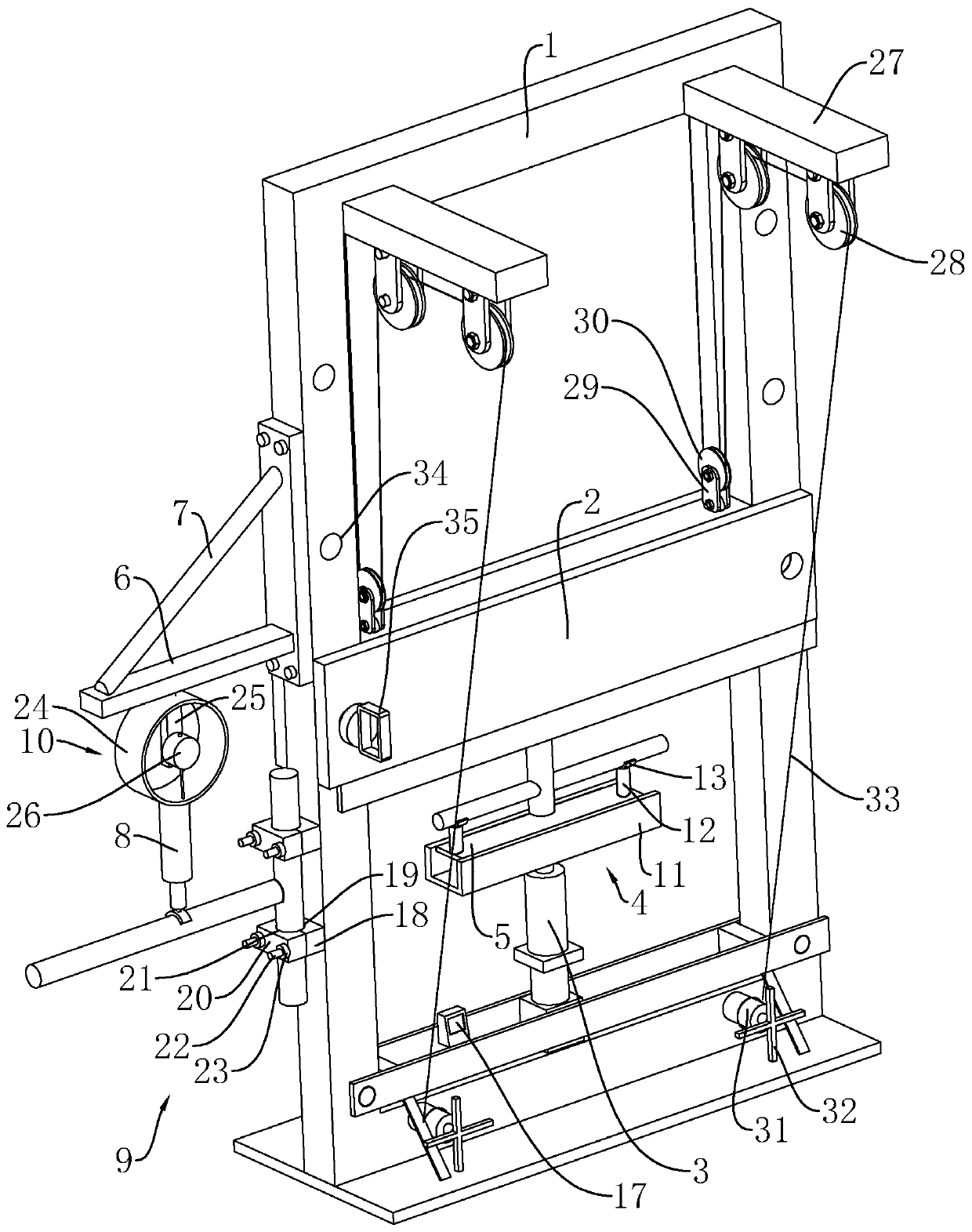

[0036] A scaffold bearing force detection device, such as figure 1 Shown: including a support frame 1, the support frame 1 is provided with a force rod 2.

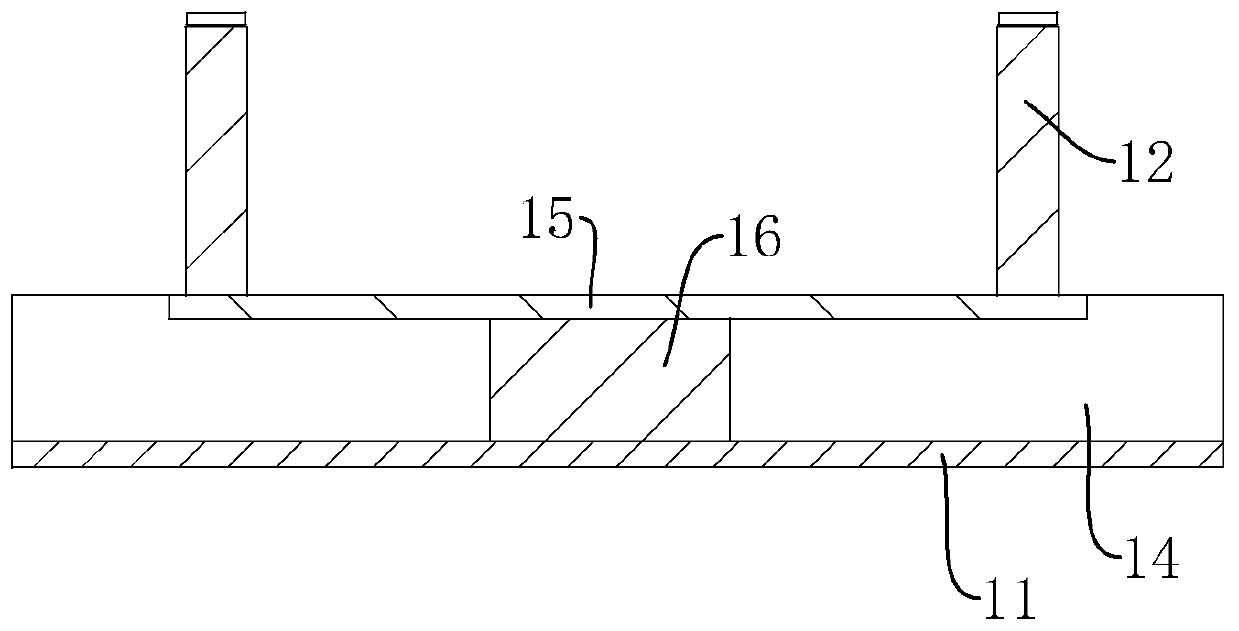

[0037] The support frame 1 is provided with a first hydraulic cylinder 3, the first hydraulic cylinder 3 is upright, the first hydraulic cylinder 3 is provided with a first clamp 4 for cooperating with the cross-shaped steel frame, and the first clamp 4 is provided with a First measurement component 5 of the shear force of the cruciform steel frame. When measuring the cross-shaped steel frame, the cross-shaped steel frame is fixed by the first clamp 4, the first clamp 4 is lifted by the first hydraulic cylinder 3, and the cross-shaped steel frame of the force rod 2 is not in contact with the first clamp 4 Part of the force passes through the first measuring component 5, thereby measuring the shear force of the welding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com