A high temperature and corrosion resistant airtight slag discharge valve with temperature measurement

A technology of corrosion-resistant and slag-discharging valves, which is applied in the direction of lifting valves, shaft seals, valve devices, etc., can solve problems such as insufficient high-temperature corrosion resistance, poor sealing performance, strong sulfur corrosion, etc., and achieve good corrosion resistance, The effect of improving life and reducing arching stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

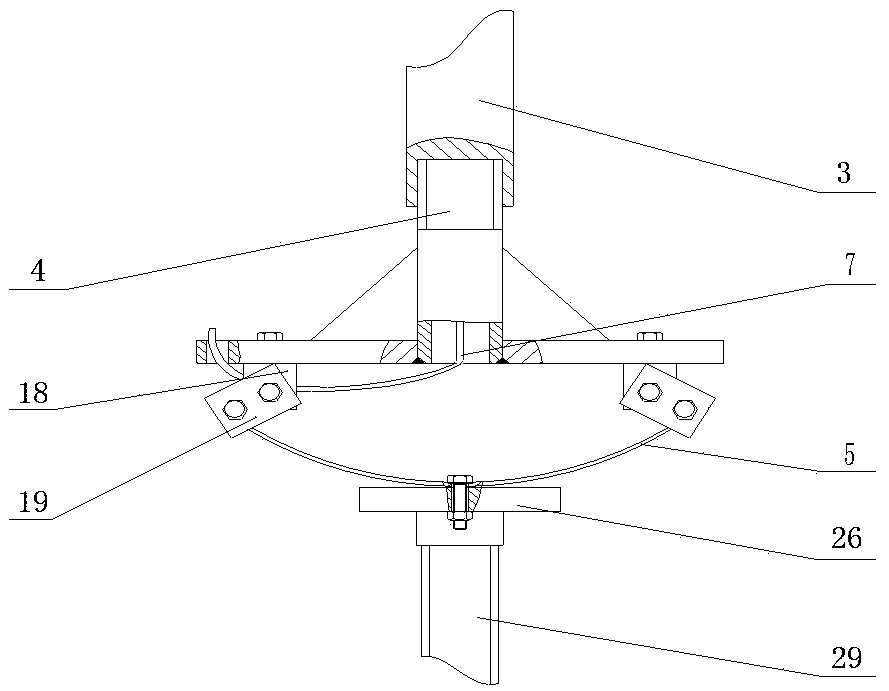

[0027] This embodiment provides a high temperature and corrosion resistant airtight slag discharge valve with temperature measurement, such as figure 1 As shown, it includes outer barrel, valve core 1, valve seat 2, valve stem 3, connecting frame 4, leaf spring 5, elevator 6 and temperature measuring element 7; the top surface of the outer barrel is provided with a slag inlet, and There is a slag discharge port, and a deflector 8 that is inclined downward and communicates with the slag discharge port is arranged inside; the valve seat 2 is made of ceramics and is arranged below the slag discharge port; the valve core 1 is made of ceramics, such as figure 2 As shown, it includes the bottom of the spool 1.1, the spherical surface 1.2 of the spool extending upward along the edge of the bottom 1.1 of the spool, the anti-camber surface 1.3 of the spool concave inward along the edge of the spherical surface 1.2 of the spool and the anti-camber surface 1.3 along the spool Surface 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com