A Realization Method and Vibration Absorber Based on Hardened Cubic Stiffness

A cubic rigidity and realization method technology, applied in the direction of transmission, belt/chain/gear, inertial force compensation, etc., to achieve the effects of saving space, high reliability, and easy measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

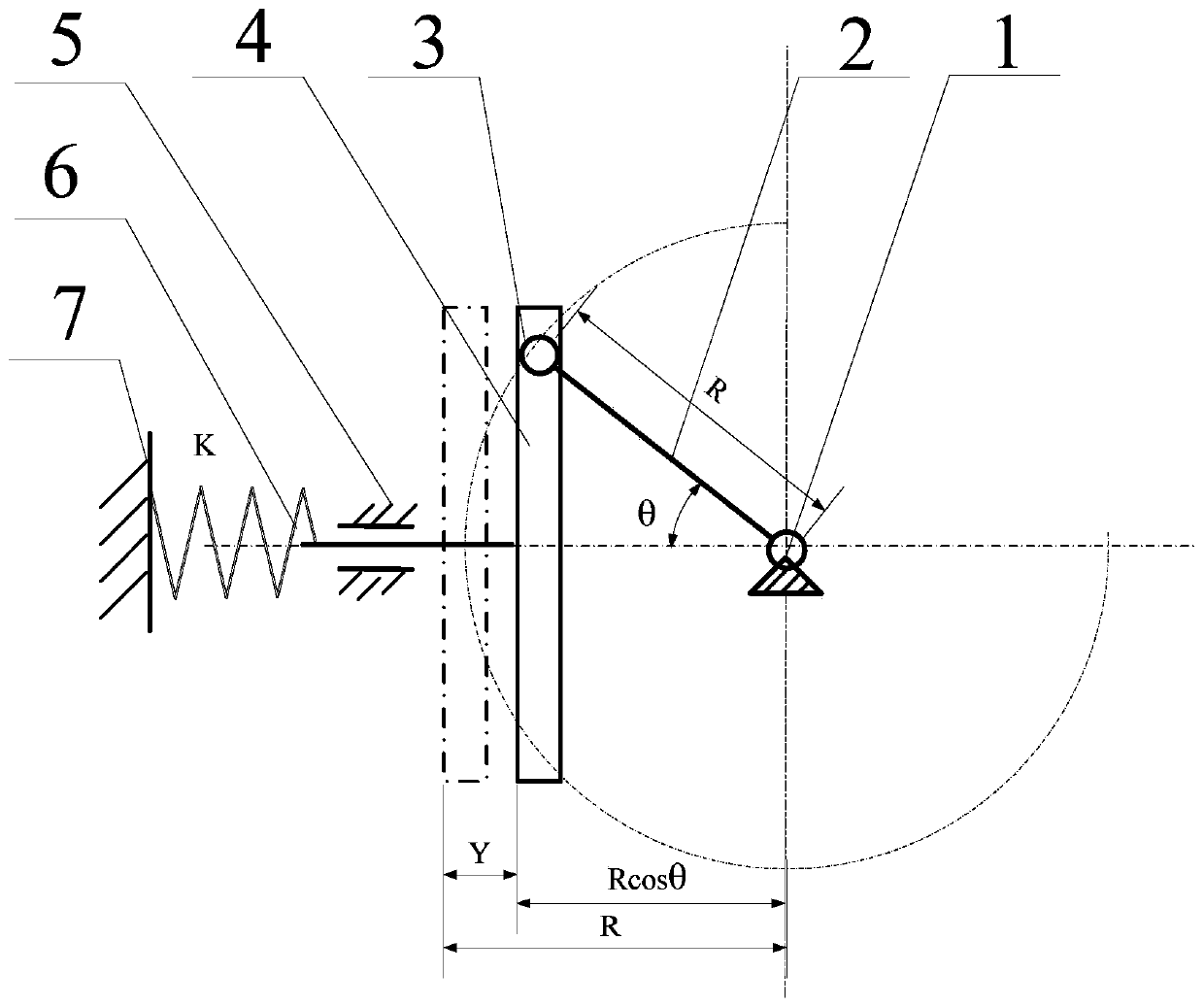

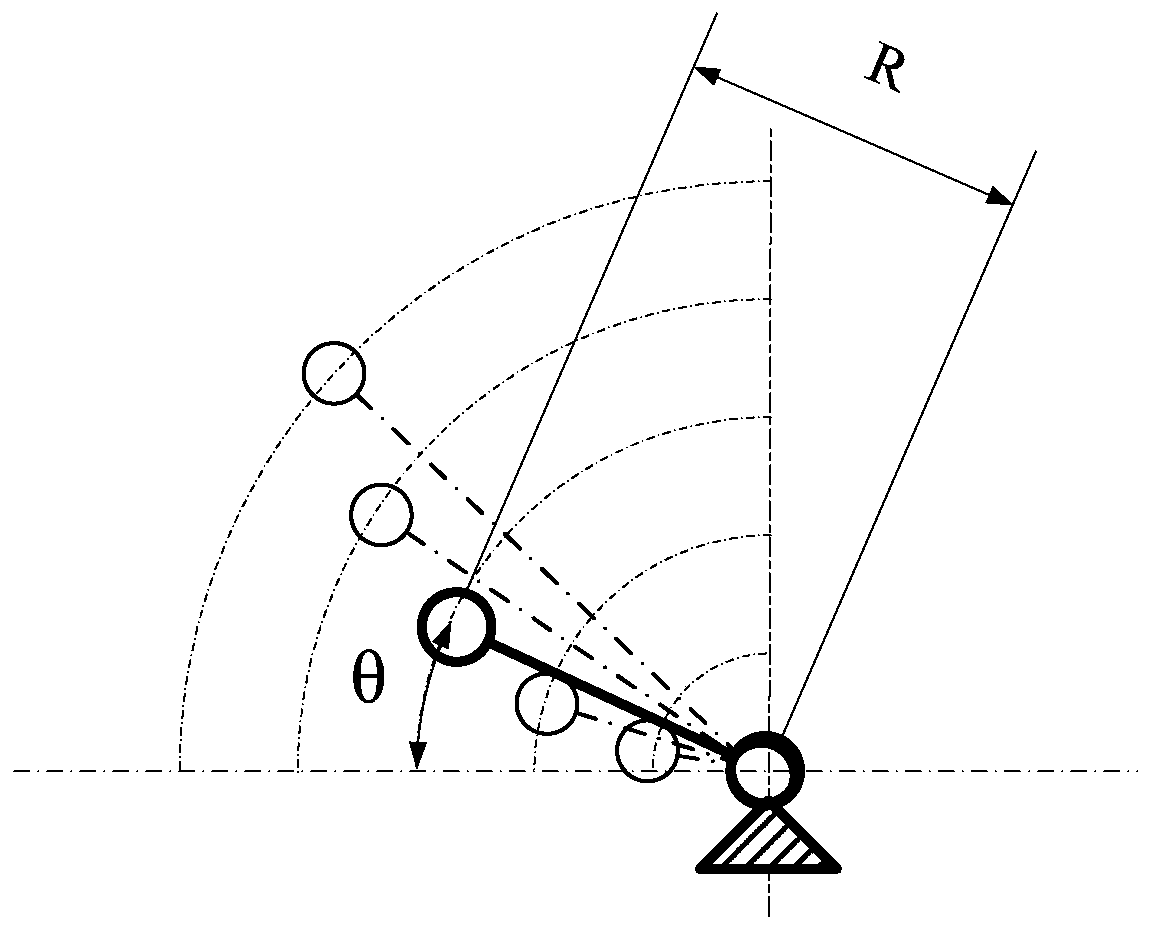

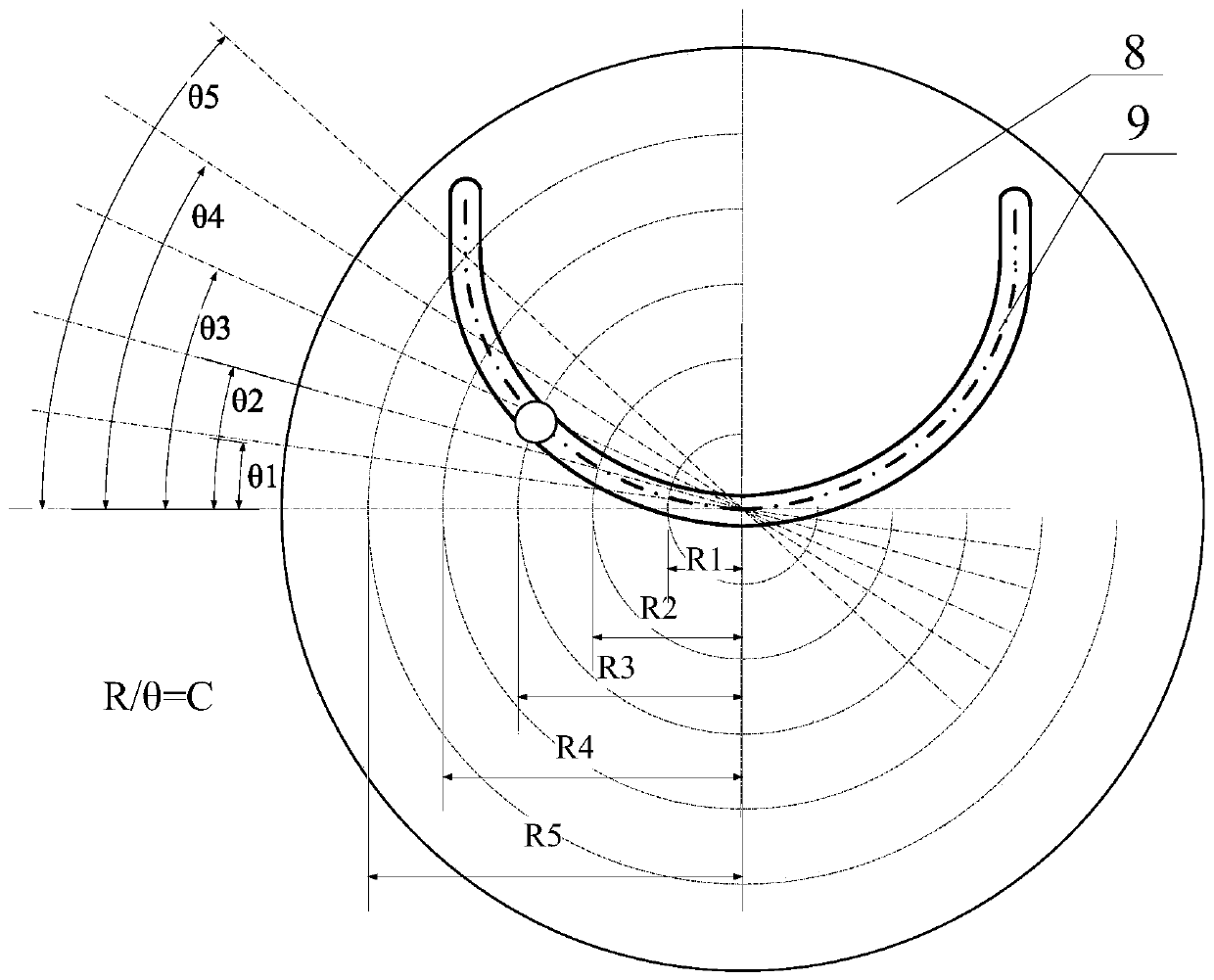

[0023] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the main structure of the present invention is a sinusoidal mechanism, including a support 1, a rocking bar 2, a roller 3, a slider 4, a sliding guide rail 5, an elastic element 6 and a spring support 7; the rocking bar 2 is an input end, and the The bracket 1 rotates, the rocker 2 drives the slider 4 to move linearly through the roller 3 , and the slider 4 is connected with the spring support 7 through the elastic element 6 . The slider 4 is restricted by the sliding track 5 to move in a straight line parallel to it. There is an inner track perpendicular to the movement direction inside the slider 4. The sliding track 5 and the rotation center of the rocker 2 are on a straight line. When the rocker 2 swings at a certain angle θ , the roller 3 at the end of the rocker will push the slider through the inner track of the slider 4 to make a linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com