Foundation module for fabricated house

A prefabricated, housing technology, applied in wine cellars, building components, buildings, etc., can solve the problems affecting the bearing capacity and safe use of the house, the complicated operation of the house foundation, and the sinking of the house foundation. Guaranteed bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

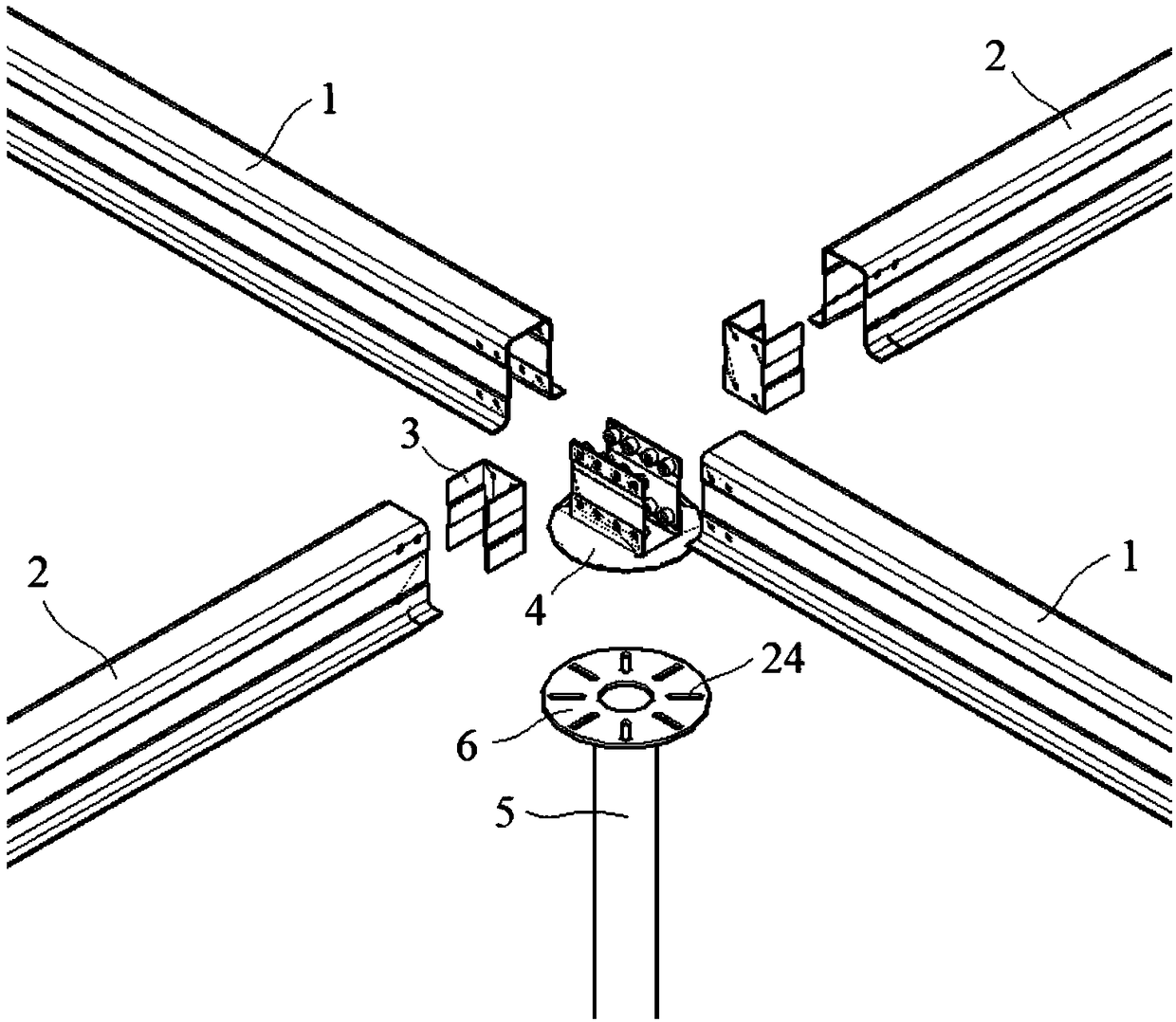

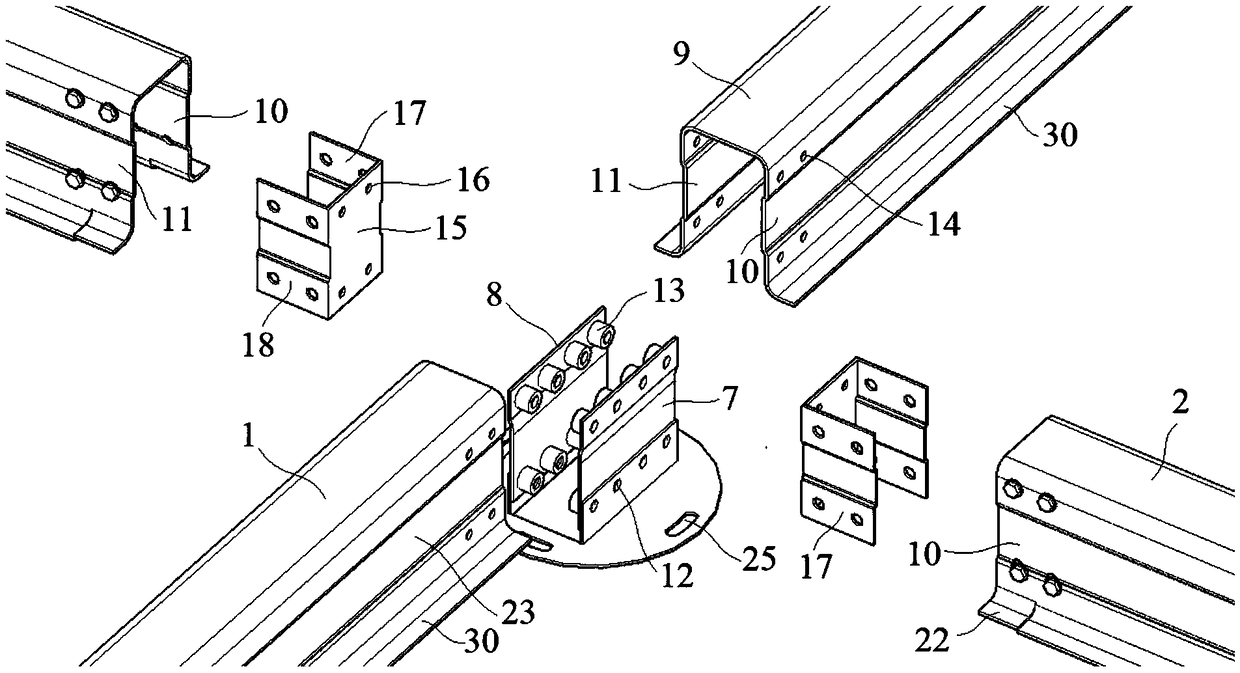

[0025] Embodiment 1: A foundation module for a prefabricated house, including 2 X beams 1, 2 Y beams 2, 2 connectors 3, connection plates 4 and ground piles 5, the 2 X beams 1 The two Y beams 2 are respectively installed and connected to the connection plate 4 and the X beam 1 through two connectors 3, and the ground pile 5 is installed on the lower surface of the connection plate 4 through a mounting plate 6. , the upper surface of the connection plate 4 is symmetrically provided with a first vertical plate 7 and a second vertical plate 8, and the two ends of the first vertical plate 7 are respectively installed and connected with two X beams 1, and the two ends of the second vertical plate 8 are The ends are installed and connected with two X beams 1 respectively;

[0026] The X beam 1 and the Y beam 2 further include a top plate 9 and a first side plate 10 and a second side plate 11 positioned on both sides of the top plate 9, and the first vertical plate 7 and the second v...

Embodiment 2

[0030] Embodiment 2: A foundation module for a prefabricated house, including 2 X beams 1, 2 Y beams 2, 2 connectors 3, connection plates 4 and ground piles 5, the 2 X beams 1 The two Y beams 2 are respectively installed and connected to the connection plate 4 and the X beam 1 through two connectors 3, and the ground pile 5 is installed on the lower surface of the connection plate 4 through a mounting plate 6. , the upper surface of the connection plate 4 is symmetrically provided with a first vertical plate 7 and a second vertical plate 8, and the two ends of the first vertical plate 7 are respectively installed and connected with two X beams 1, and the two ends of the second vertical plate 8 are The ends are installed and connected with two X beams 1 respectively;

[0031]The X beam 1 and the Y beam 2 further include a top plate 9 and a first side plate 10 and a second side plate 11 positioned on both sides of the top plate 9, and the first vertical plate 7 and the second ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com