Constructing method of constructing structure of underwater bearing platform

A construction method and platform technology, which are applied in underwater structures, infrastructure engineering, construction, etc., can solve the problems that the back-sealing concrete does not play the role of back-sealing, affect the structural stability of the platform, and the construction positioning is inaccurate, etc. The effect of avoiding conflicts, alleviating constraints, and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention. In order to demonstrate the actual construction method of the underwater cap construction structure, the following embodiments will introduce the underwater cap and specific components, so that the application and connection relationship of the underwater cap construction structure can be displayed more clearly It is sufficient and easy to understand that it is worth noting that the protection scope of the present invention is not limited.

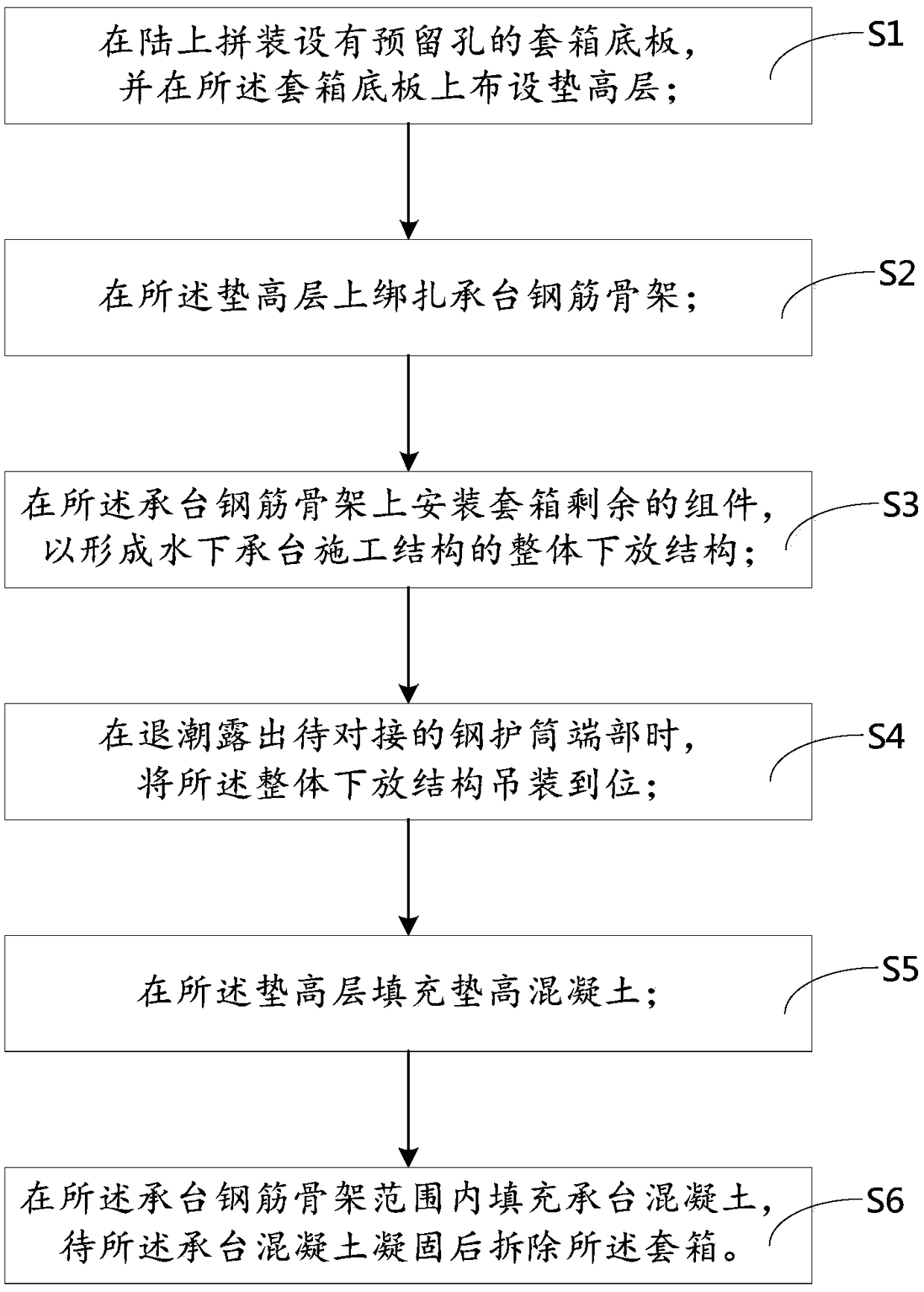

[0052] Please refer to figure 1 , figure 1 The specific steps of a construction method of an underwater cap construction structure are shown, specifically including:

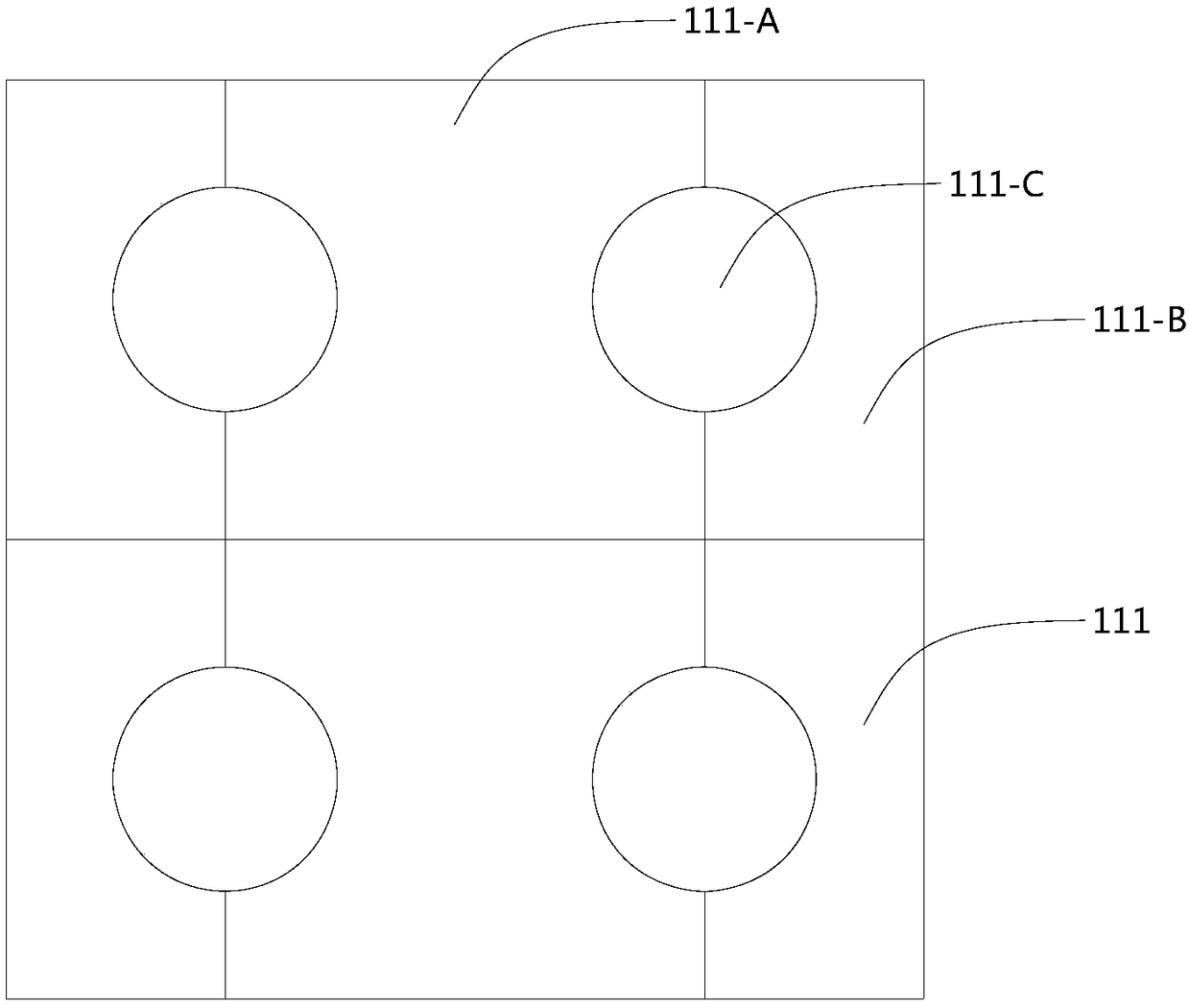

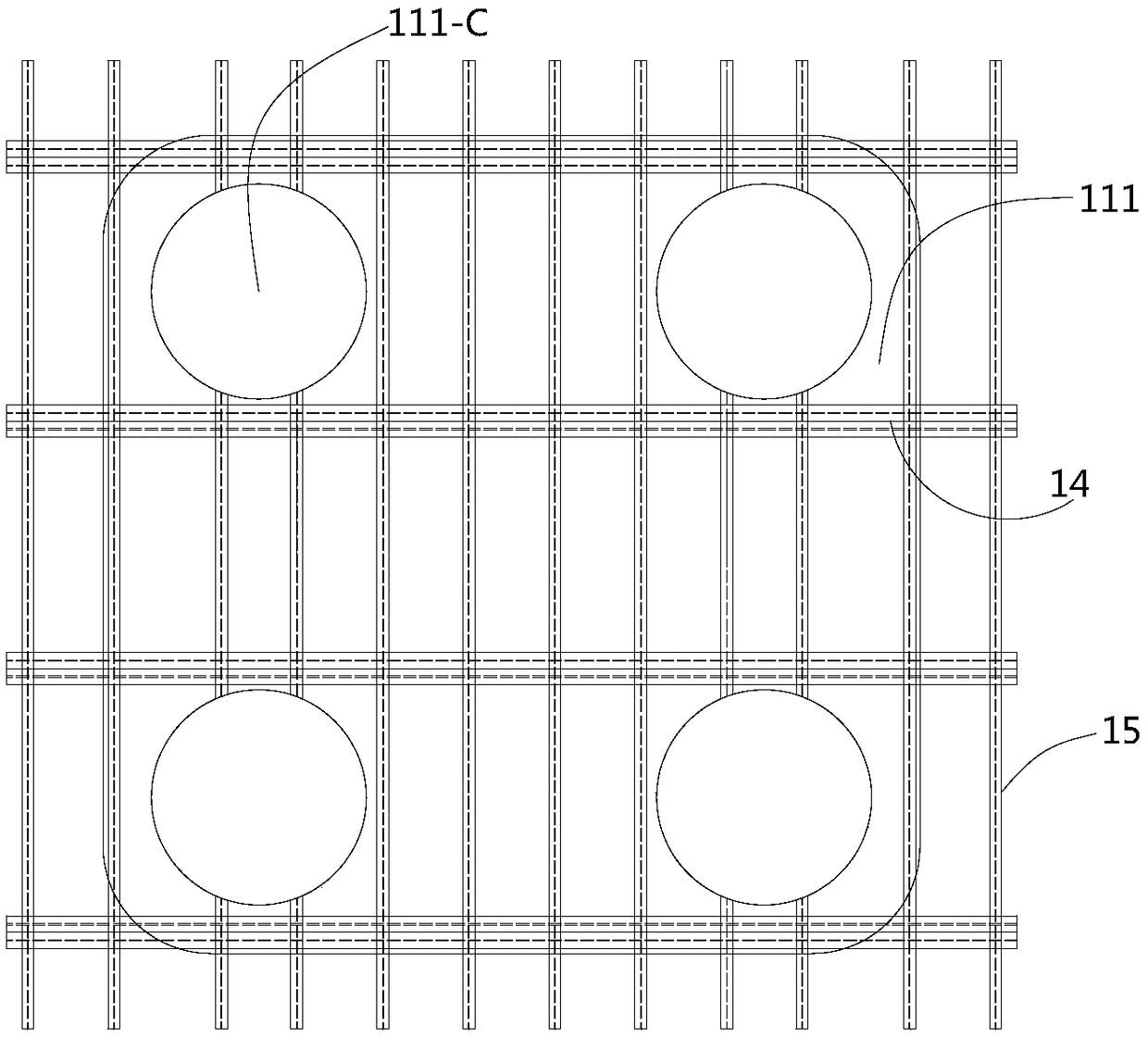

[0053] Step S1: Please combine Figure 4 auxiliary reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com