Cloth dyeing device and cloth dyeing method utilizing device

An equipment and technology for dyeing cloth, applied in the field of printing and dyeing, can solve the problems of poor dyeing effect at the crease, prone to discounts, and reduced quality of dyed cloth, so as to achieve better dyeing cloth quality, reduce discounts, and improve the effect of penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

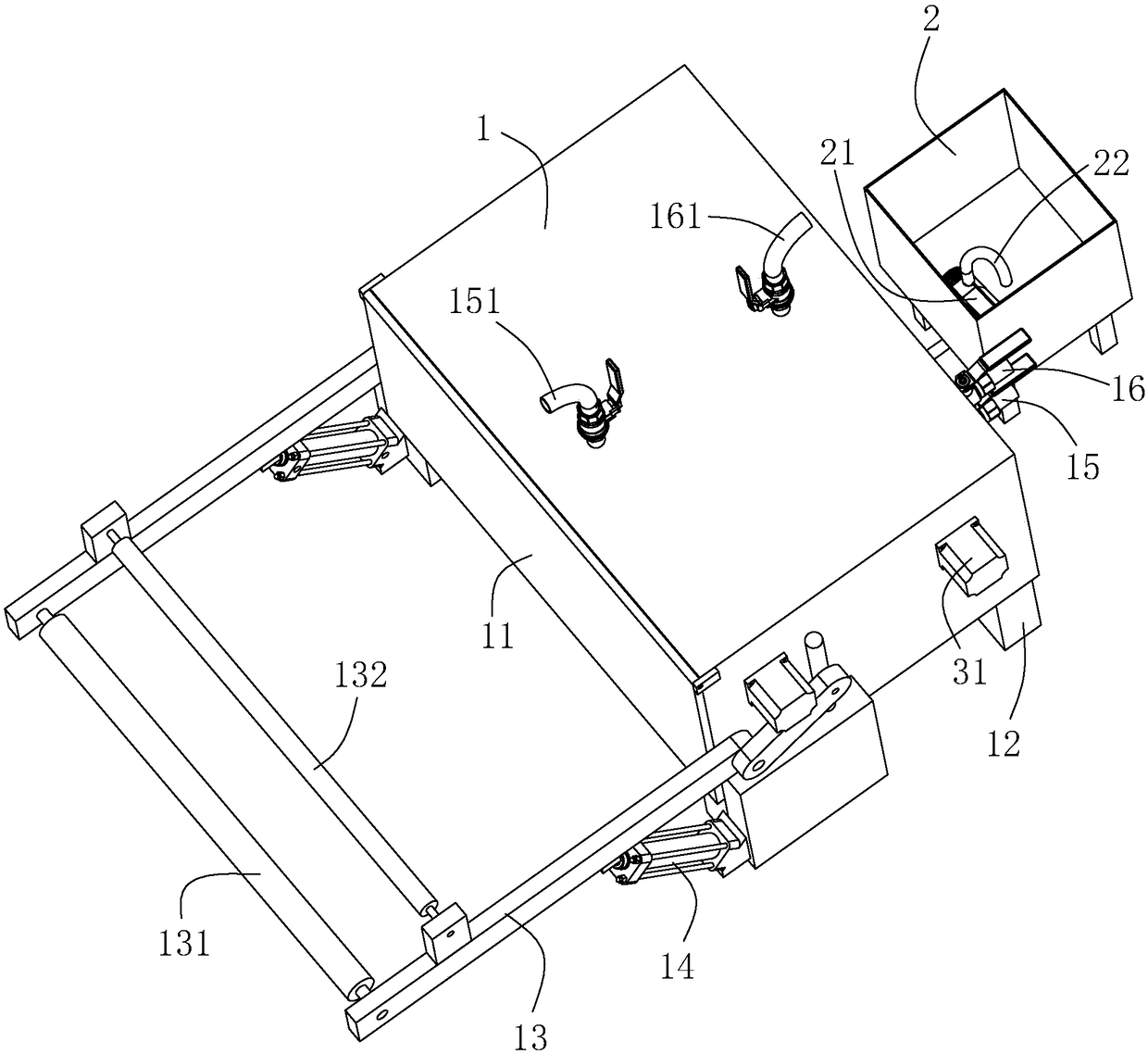

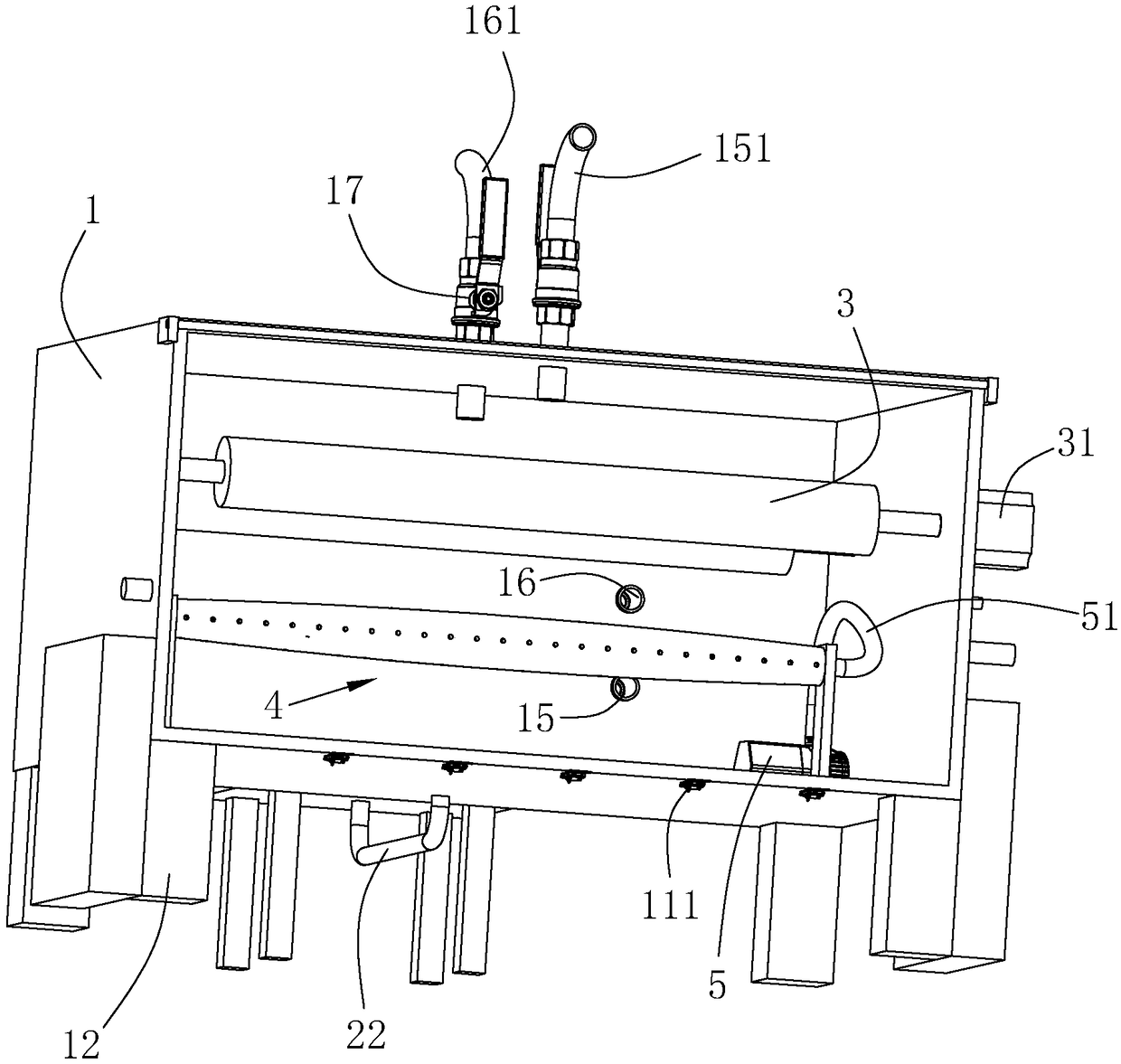

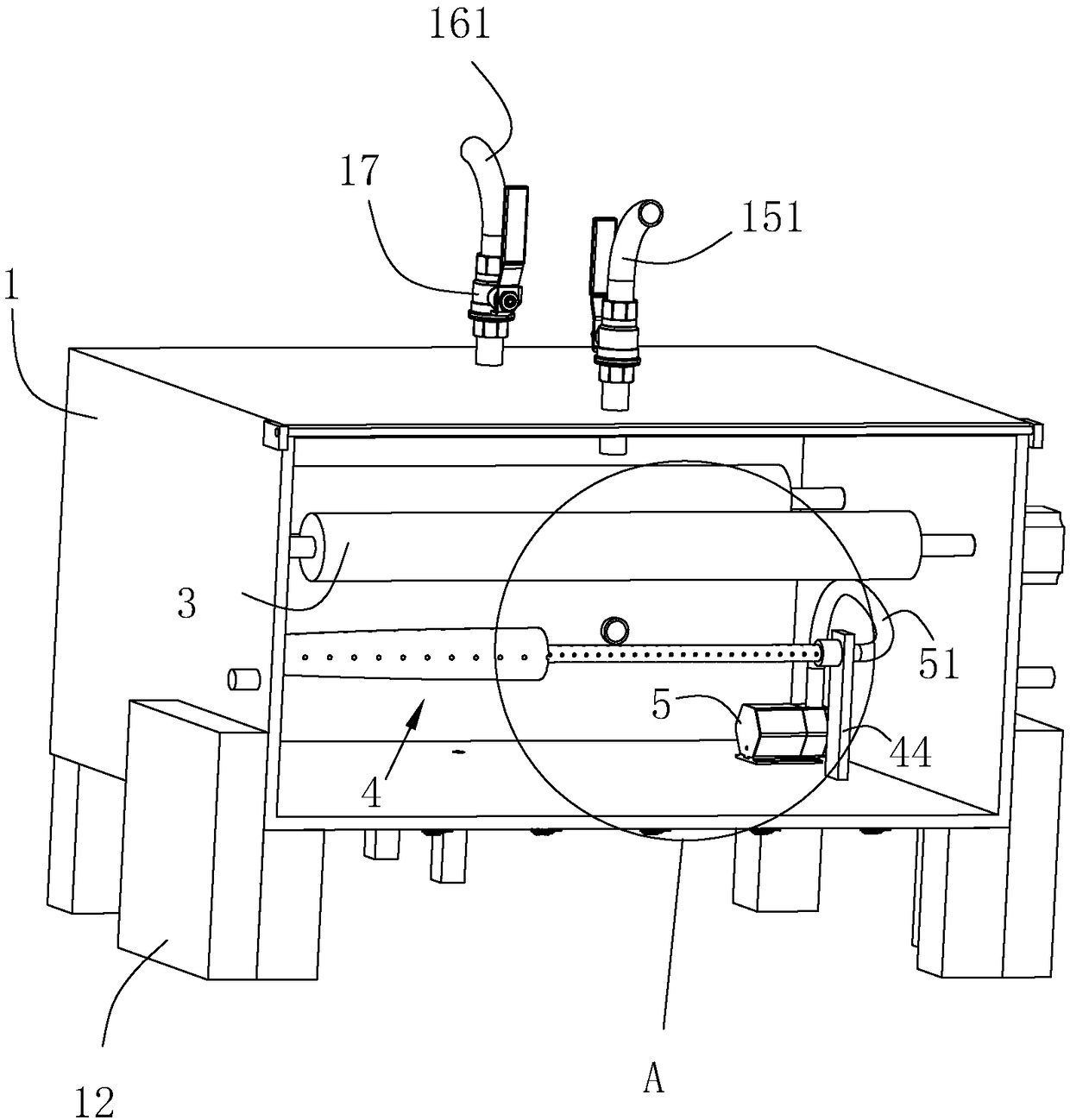

[0054] A kind of cloth dyeing equipment, refer to figure 1 as well as figure 2 , including the main dyeing vat 1 and the secondary dyeing vat 2 connected with the main dyeing vat 1, a pair of cloth rolling rollers 3 are rotatably connected in the main dyeing vat 1, and the main dyeing vat 1 is also fixed with a motor 31 that drives the cloth rolling roller 3 to rotate. A tension roller 4 whose level is lower than that of the cloth rolling roller 3 is rotatably connected, and a number of injection holes 411 respectively facing the two ends of the tension roller 4 run through the side wall of the tension roller 4 .

[0055] A temperature sensor (not shown in the figure) and a pressure sensor (not shown in the figure) are fixed in the main dyeing vat 1, there are two temperature sensors, one is located at the top of the main dyeing vat 1, the other is located at the bottom of the main dyeing vat 1, and the pressure sensor is located at On the top of the main dyeing vat 1, a sti...

Embodiment 2

[0072] A kind of cloth dyeing method utilizing the cloth dyeing equipment of embodiment 1, with reference to Figure 5 , including the following steps:

[0073] S001 cloth feed, details are as follows:

[0074] Put down the swing arm 13, then wind the cloth on the cloth feeding roller 131, open the cylinder cover 11, wind the cloth on the cloth winding roller 3 close to the cloth feeding roller 131, and then take one end of the cloth from the tension roller 4 The bottom passes through and is wound on the cloth roll 3 away from the cloth feed roller 131, and then the cylinder cover 11 is closed to seal.

[0075] S002 dry, as follows:

[0076] Inject high-temperature gas through the high-temperature gas injection pipe 16 until the pressure in the main dyeing vat 1 is 0.2 MPa, then reduce the injection amount of the high-temperature gas injection pipe 16, and discharge the high-temperature gas through the high-temperature gas extraction pipe 161 to maintain a constant pressure ...

Embodiment 3

[0095] The difference from Example 2 is that in S004, after 6 processes of dyeing the cloth, it enters the heat preservation stage and heats it for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com