A treatment method and treatment device for high-salt wastewater produced by crude glycerin purification

A high-salt wastewater and treatment method technology, applied in water/sewage treatment, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as difficulty in meeting discharge requirements, inability to oxidize and degrade organic matter, and inorganic salt pollution , to achieve the effect of low processing cost, realizing recycling and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

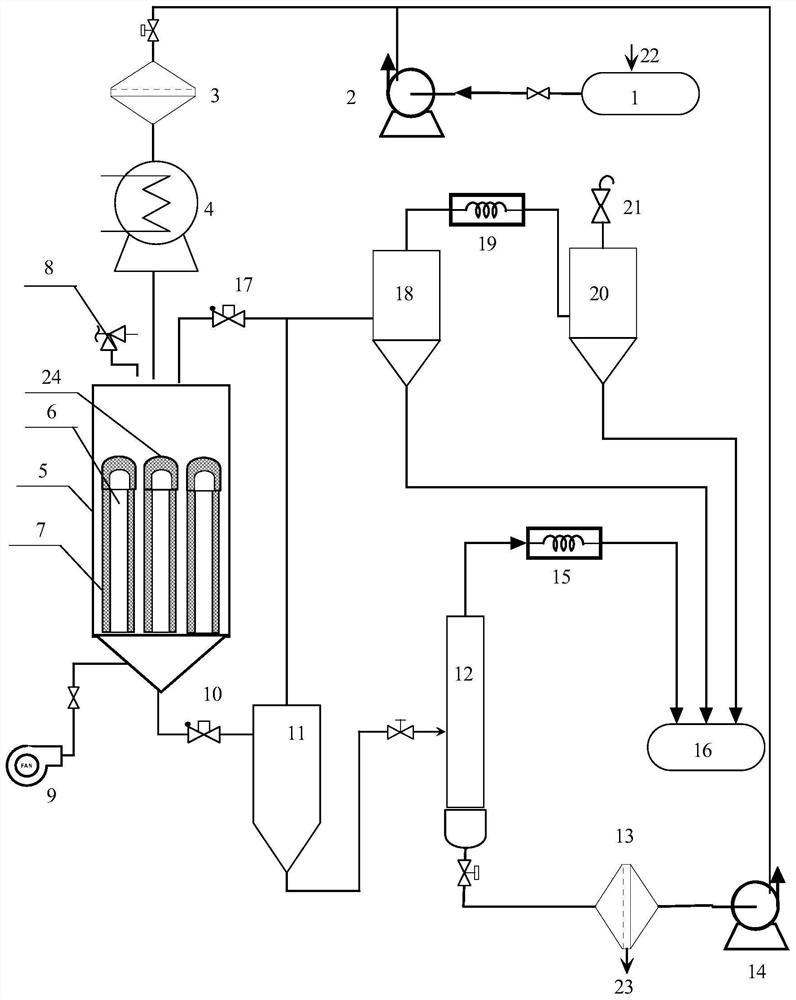

Method used

Image

Examples

Embodiment 1

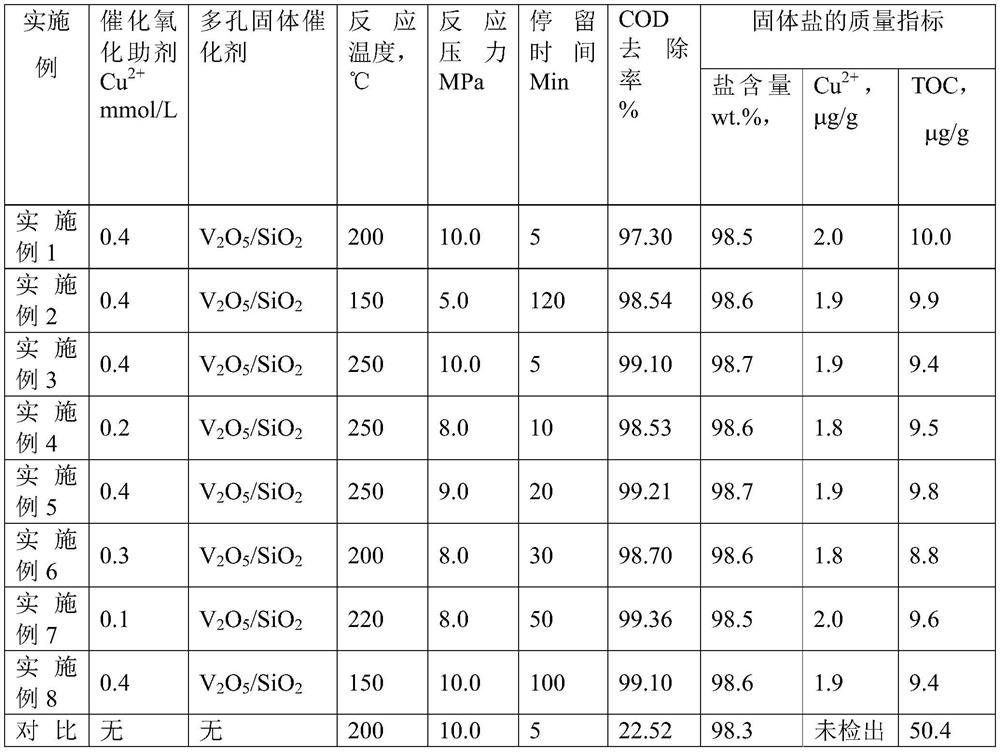

[0039] Add the high-salt wastewater produced by the purification of crude glycerin into the wastewater storage tank, add the catalytic oxidation aid anhydrous copper chloride and stir evenly, then preheat, and after preheating, enter the V 2 o 5 / SiO 2 In the oxidation reactor, it reacts with the oxidant, and controls the temperature, pressure, flow rate and residence time of the reaction; after the reaction is completed, samples are taken at the outlet of the oxidation reactor for analysis, and then the treated organic wastewater enters the flash device, and the temperature is lowered. The solid salt is separated by centrifugation through the desalination filter, and the concentrated liquid after centrifugation is returned to the filter device, then enters the preheating device, and is applied to the process to realize the recycling of catalytic oxidation additives. The treated organic wastewater was measured for COD and calculated for its removal rate, and analyzed after dr...

Embodiment 2

[0044] The processing is as in Example 1.

[0045] The process parameters are:

[0046] (1) NaCl content is 17.0wt.% in the high-salt wastewater produced by crude glycerin purification, and COD is 90000mg / L; After adding anhydrous copper chloride in the high-salt wastewater produced by crude glycerin purification, Cu 2+ The molar concentration in the high-salt wastewater produced by crude glycerin purification is 0.4mmol / L; the preheating temperature is 150°C; the reaction temperature is 150°C, the reaction pressure is 5.0MPa, the residence time is 120min, and the wastewater flow rate is 8.3ml / min , the oxidant is air;

[0047] (2) After testing, the COD removal rate of the treated organic wastewater is 98.54%, and the recovery rate of NaCl is 99.4%. After the solid salt is dried, it is analyzed, and its quality index is: NaCl: 98.6wt.%; Cu 2+ : 1.9 μg / g; TOC: 9.9 μg / g.

Embodiment 3

[0049] The processing is as in Example 1.

[0050] The process parameters are:

[0051] (1) NaCl content is 18.0wt.% in the high-salt wastewater produced by crude glycerin purification, and COD is 80000mg / L; After adding anhydrous copper chloride in the high-salt wastewater produced by crude glycerin purification, Cu 2+ The molar concentration in the high-salt wastewater produced by crude glycerin purification is 0.4mmol / L; the preheating temperature is 250°C; the reaction temperature is 250°C, the reaction pressure is 10.0MPa, the residence time is 5min, and the wastewater flow rate is 200ml / min. The oxidizing agent is oxygen;

[0052] (2) After testing, the COD removal rate of the treated organic wastewater is 99.10%, and the recovery rate of NaCl is 99.1%. After the solid salt is dried, it is analyzed, and its quality index is: NaCl: 98.7wt.%; Cu 2+ : 1.9 μg / g; TOC: 9.4 μg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com