Fixing clamp for developing electronic product

A technology for fixing fixtures and electronic products, which is applied to manufacturing tools, workpiece clamping devices, etc., can solve the problems that fixed fixtures cannot be lifted and adjusted in height and angle, and electronic products are deformed by heat, so as to achieve more diverse device functions and prevent heat deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

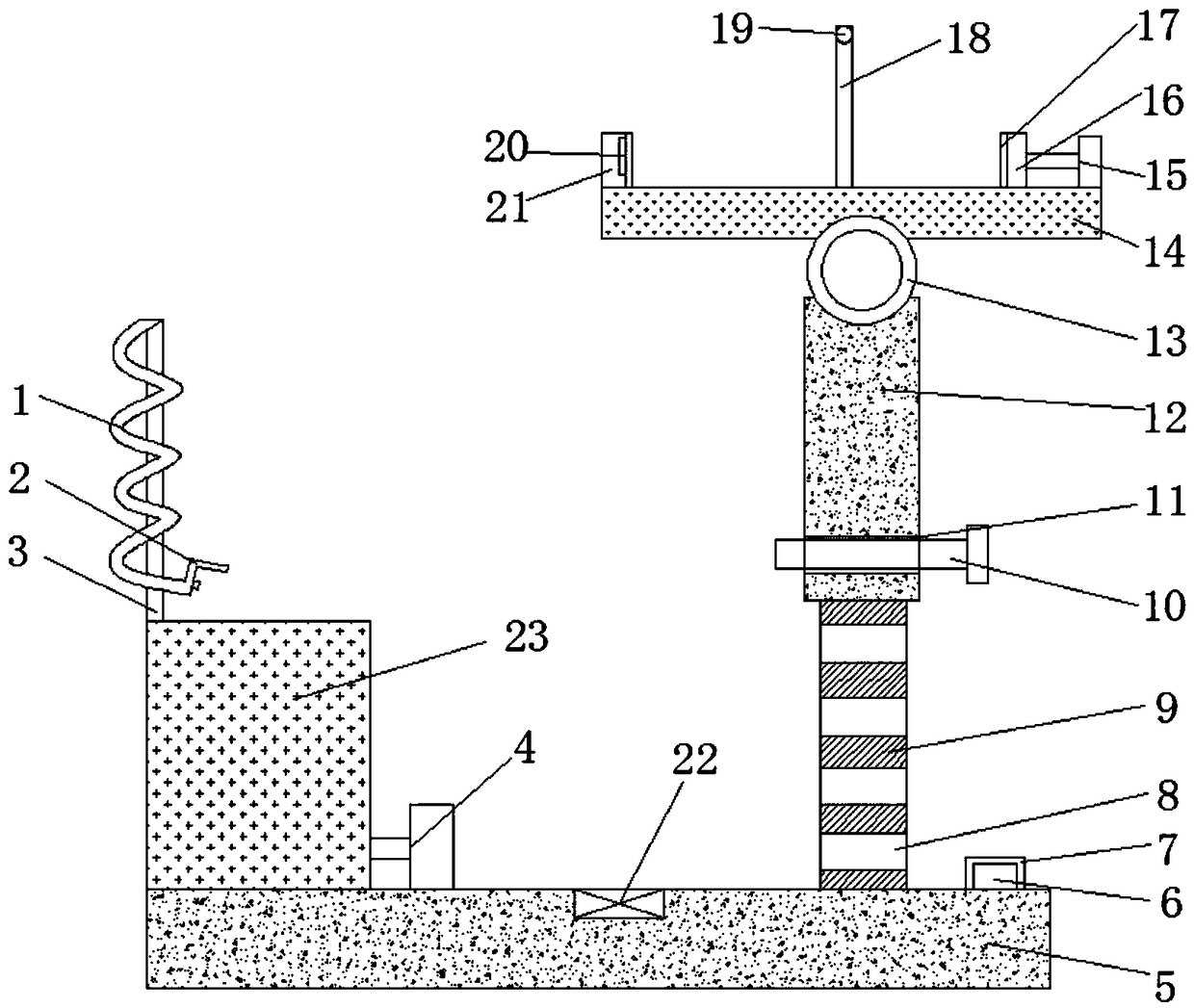

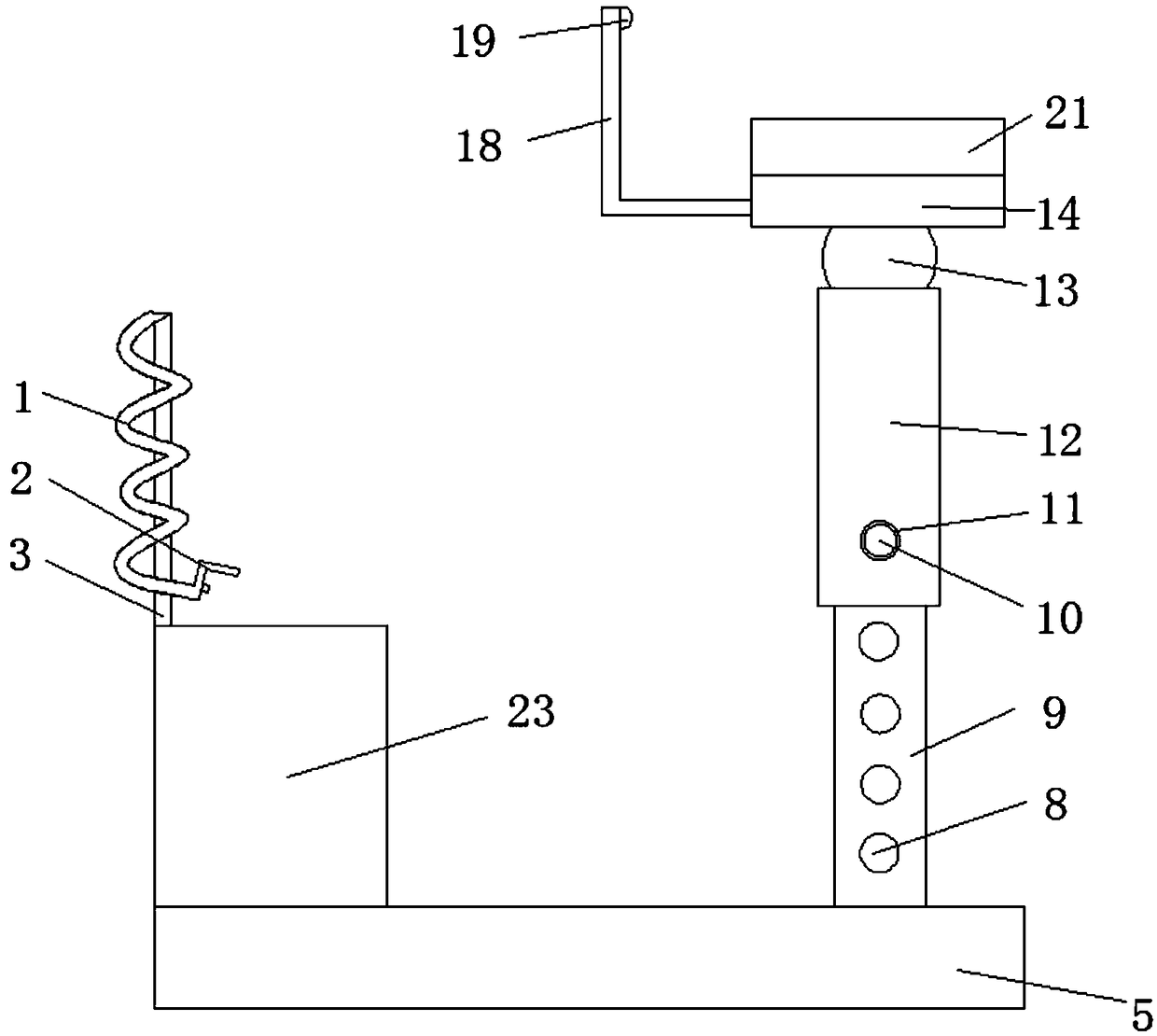

[0021] refer to Figure 1-2 , a fixing fixture for electronic product development, including a base 5, the outer wall of the top side of the base 5 is connected with a gas storage tank 23 by bolts, and a through hole is opened on the top side of the gas storage tank 23, and a stainless steel gas pipe is welded at the through hole 3. The top of the stainless steel gas pipe 3 is connected to the first hose 1 through a high-pressure pipe clamp, and the other end of the first hose 1 is connected to the air gun 2 through threads, and the outer wall of the top of the base 5 is connected to the air pump 4 through screws. The air pump 4 can give The gas storage tank 23 suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com