Probe suction device

A suction device and probe technology, applied in the direction of measuring devices, instruments, measuring electronics, etc., can solve problems such as defective products, time-consuming, small size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Referring to the drawings, where the same reference numerals represent the same components or similar components, the principles of the present invention are exemplified when implemented in a suitable computing environment. The following description is based on illustrated specific embodiments of the invention, which should not be construed as limiting other specific embodiments of the invention not described in detail herein.

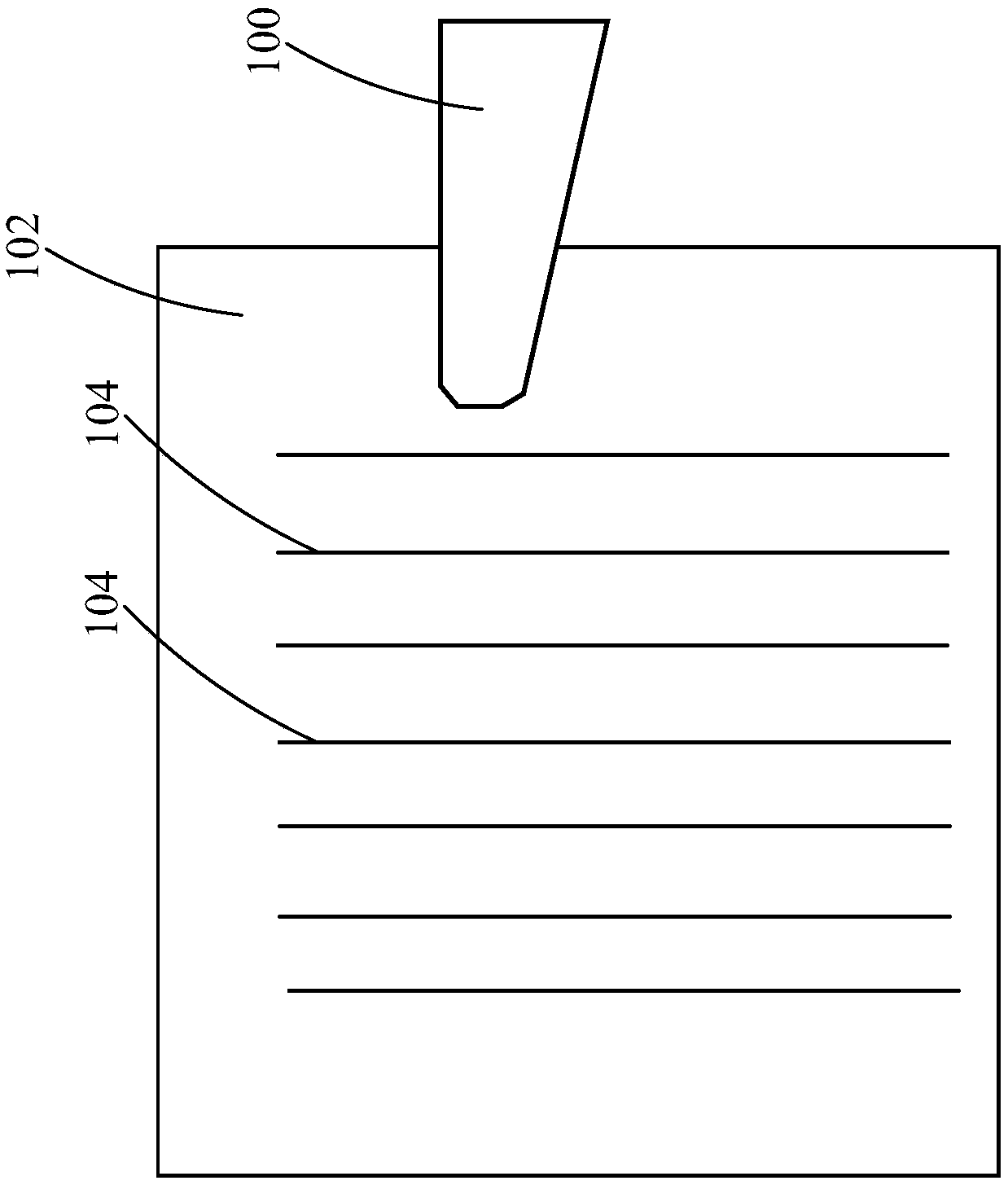

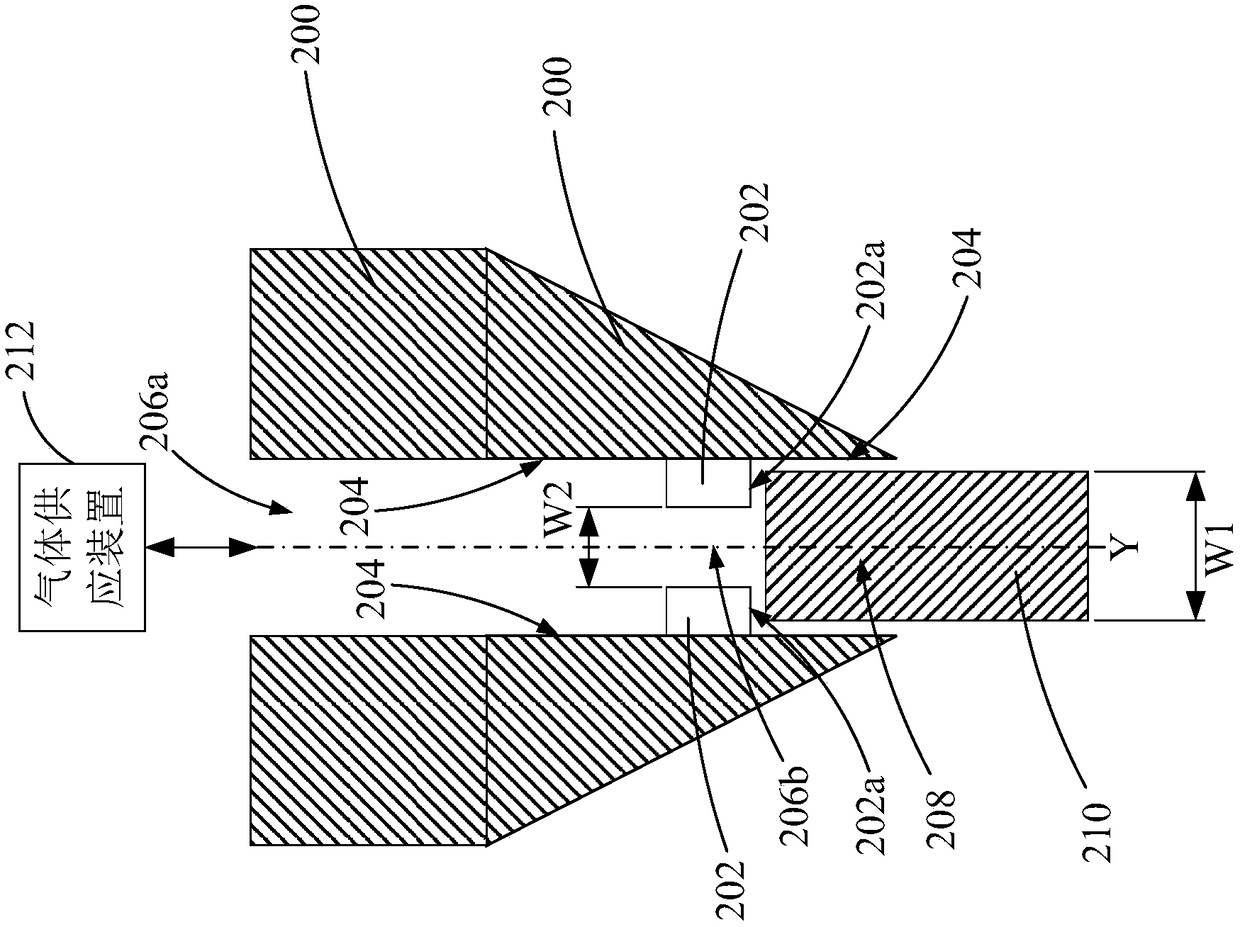

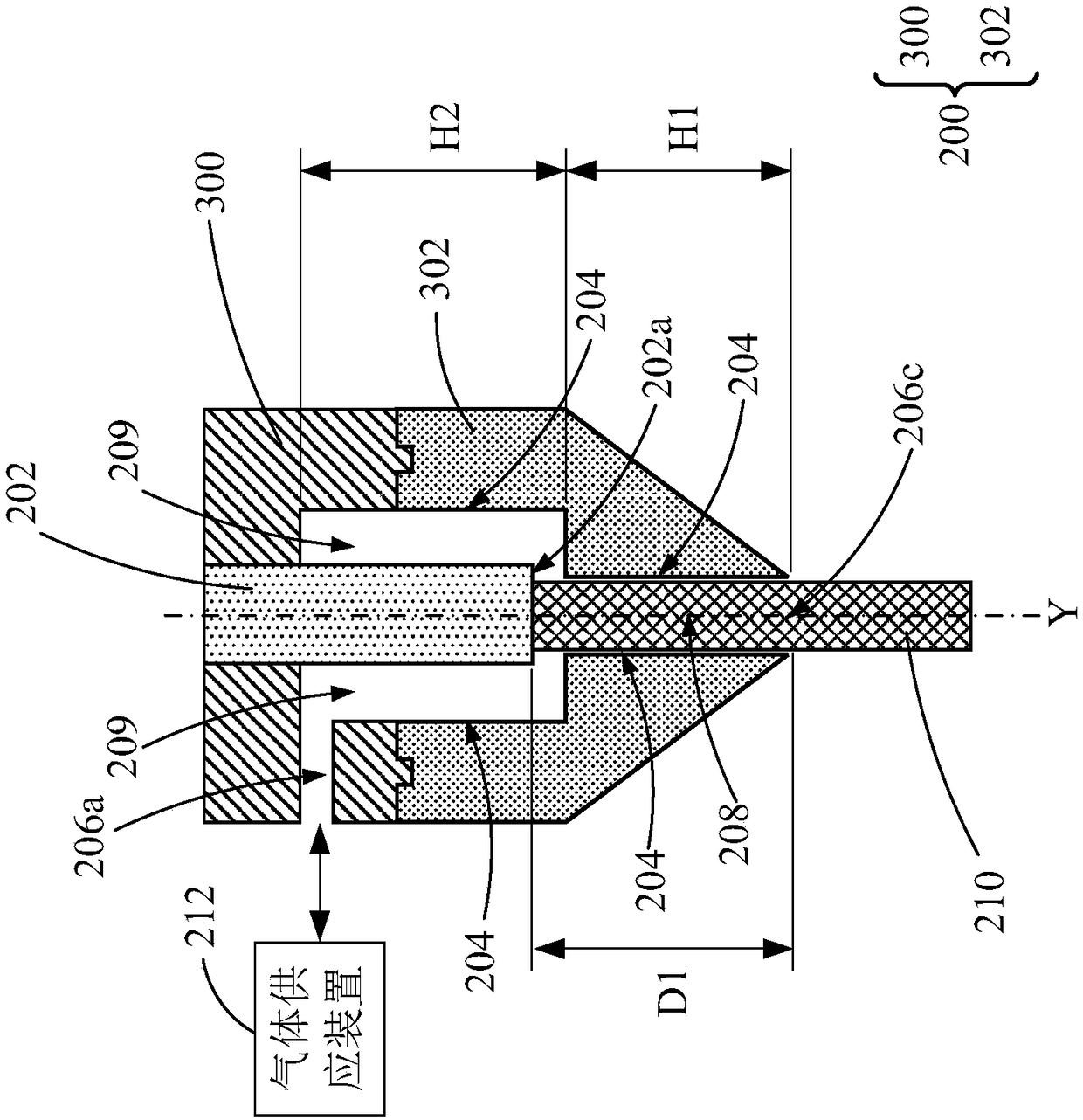

[0022] figure 2 A cross-sectional view of the probe suction device in the first embodiment of the present invention is shown. The probe suction device includes a body 200 and a stopper 202 . The body 200 has a sidewall surface 204 and a first opening 206a. The stopper 202 is fixed on the side wall surface 204, and the stopper 202 and the side wall surface 204 form a first receiving space 208, wherein the first opening 206a of the body 200 and the The first accommodating space 208 communicates, when the body 200 sucks the gas in the first acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com