Rotary pressure filter test device, test method and filter design method

A technology of test device and test method, which can be used in measuring device, by removing certain components, weighing, instruments, etc., to solve the problem of inability to obtain accurate slurry test parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

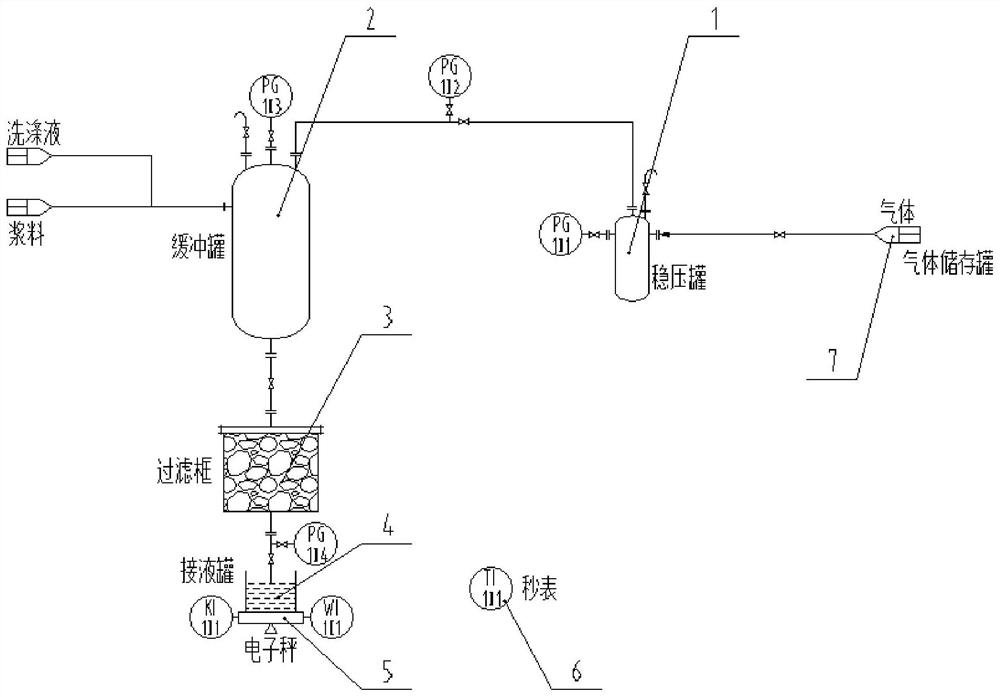

[0059] 1) Open the feed port of the buffer tank and ensure that other valves are closed. 11.26 kg of CTA slurry was poured into the surge tank and then into the filter frame.

[0060] 2) Open the valve at the air inlet of the buffer tank, pass the set 0.5MPa nitrogen into the buffer tank, open the valve at the bottom of the filter frame, filter, and time; record the filter time as 33.6s, and record the discharged The quality of the filtrate is 4.63kg; when the filtrate in the filter frame is flushed with the upper surface of the filter cake, close the valve and nitrogen valve at the bottom of the filter frame, and vent the nitrogen in the filter frame; take a sample of the filtrate to analyze the acetic acid content in the filtrate and cobalt, manganese and other impurities.

[0061] 3) Pass the dry gas of 0.5Mpa into the surge tank, fill it into the filter frame through the buffer tank, then open the valve at the bottom of the filter frame, measure the mass of the discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com