Cover film sticking test method and press machine used

A testing method and covering film technology, applied in the direction of using mechanical devices, chemical instruments and methods, lamination, etc., can solve the problem of inability to test accurately and effectively, and achieve the effect of uniform and constant pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

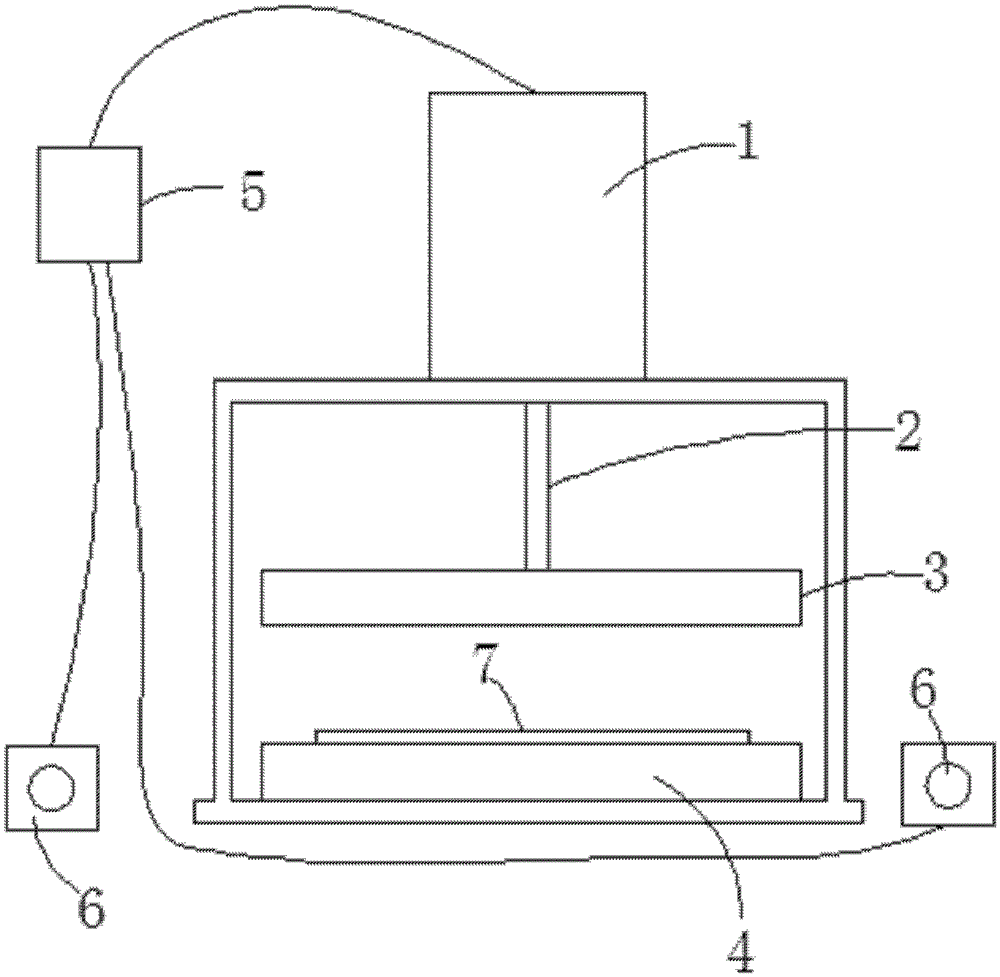

Image

Examples

Embodiment

[0024] Embodiment: a kind of covering film sticking plate test method, carry out according to the following steps:

[0025] ①. Test the amount of glue overflow of the cover film, and formulate the pressing parameters according to the amount of glue overflow. 40-80%.

[0026] ②. Cut the covering film to a width of 5cm and a length of 25 to 40cm, then tear off the release paper and paste the covering film. It must be flat and free of air bubbles when pasting, and then use a pressing machine to cover the pasted The film is cold pressed and the pressure is controlled at 0.2kgf / cm 2 to 0.6kgf / cm 2 , The pressing time is 5 seconds. ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com