Method for detecting air leakage rate of ring cooler based on blind source separation single-side detection method

A technology of blind source separation and detection method, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve unloading temperature burns, conveyor belt production accidents, lack of effective means for air leakage rate, and waste of energy for blowers and other problems, to achieve the effect of low implementation cost, good real-time performance, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

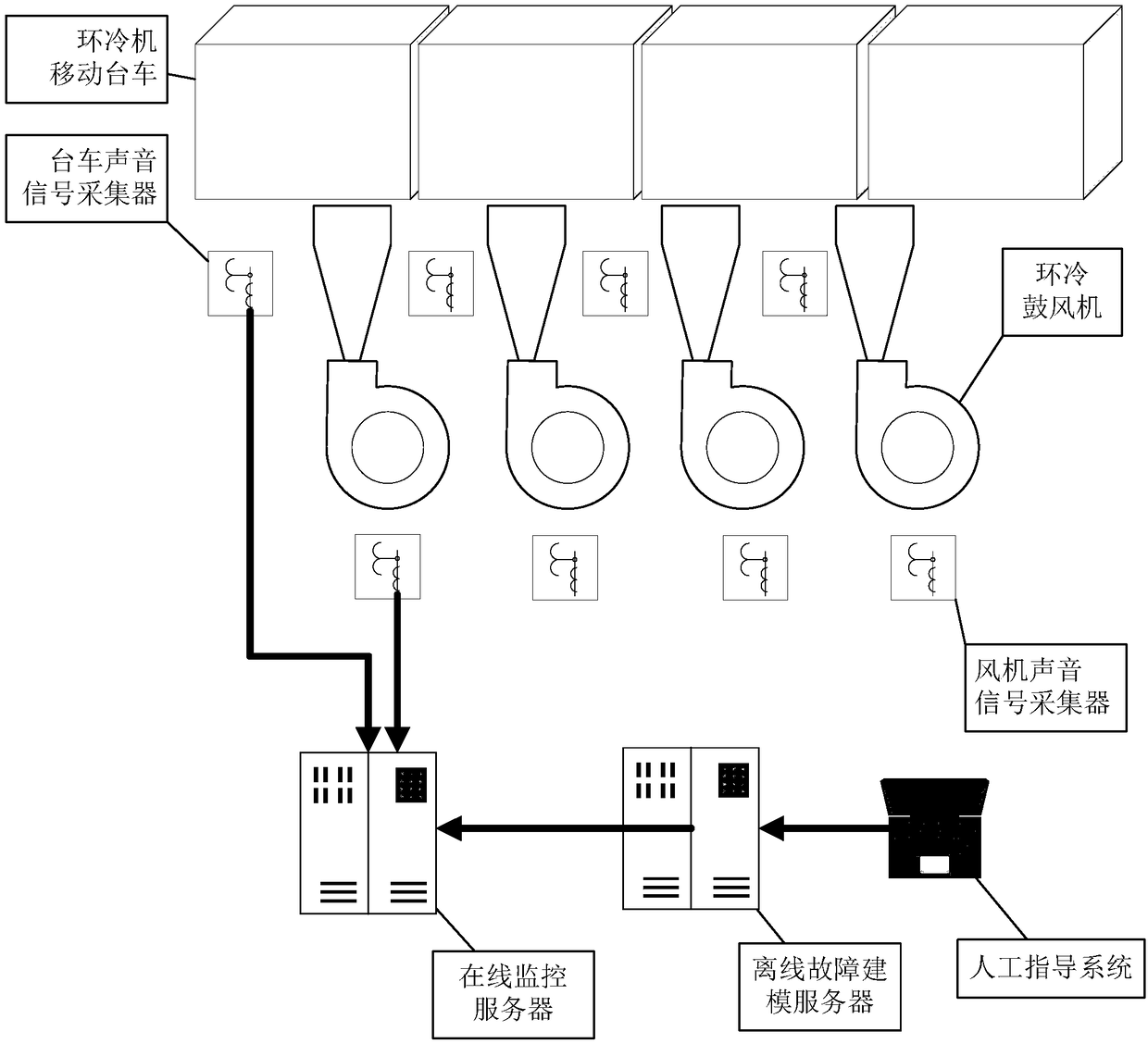

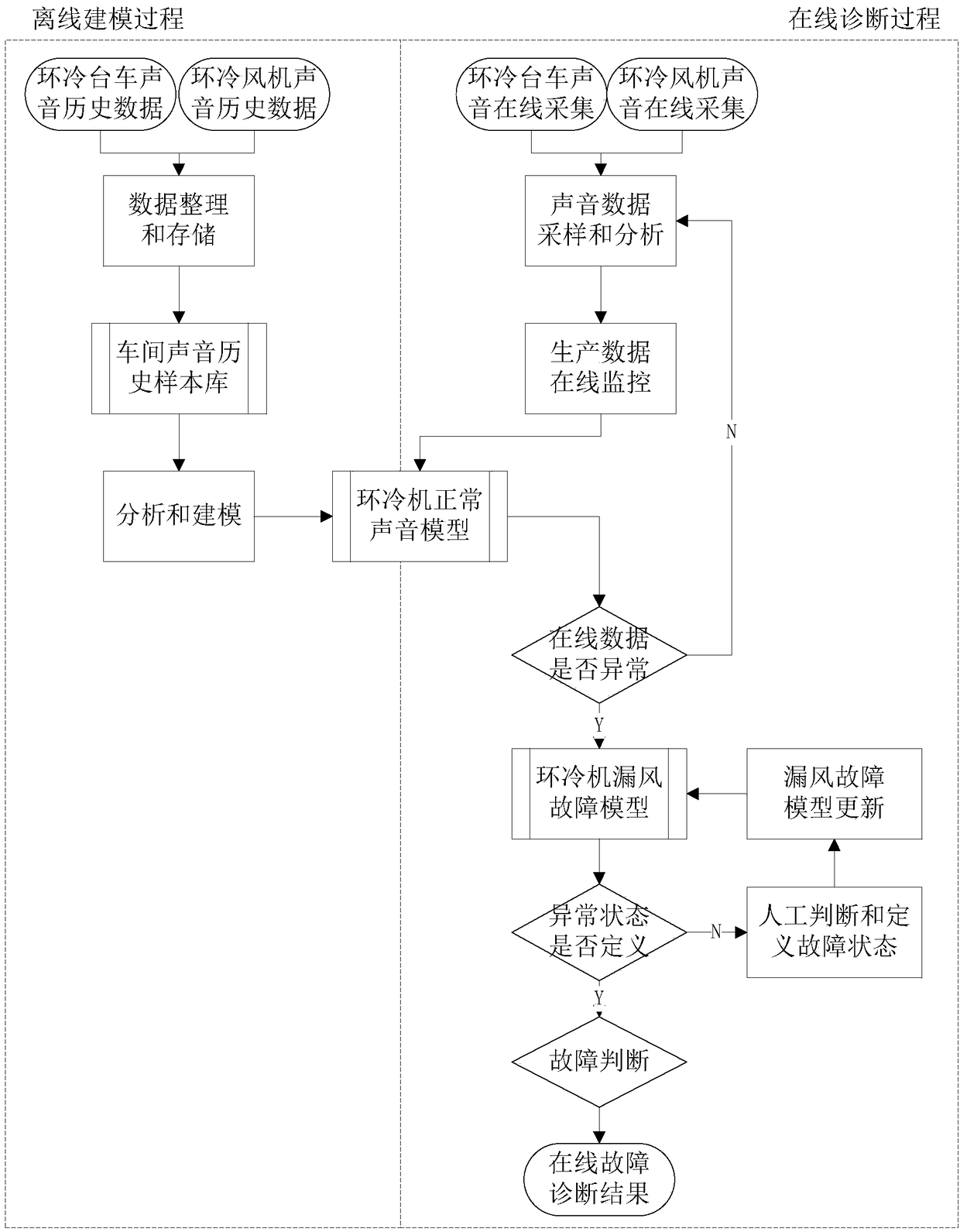

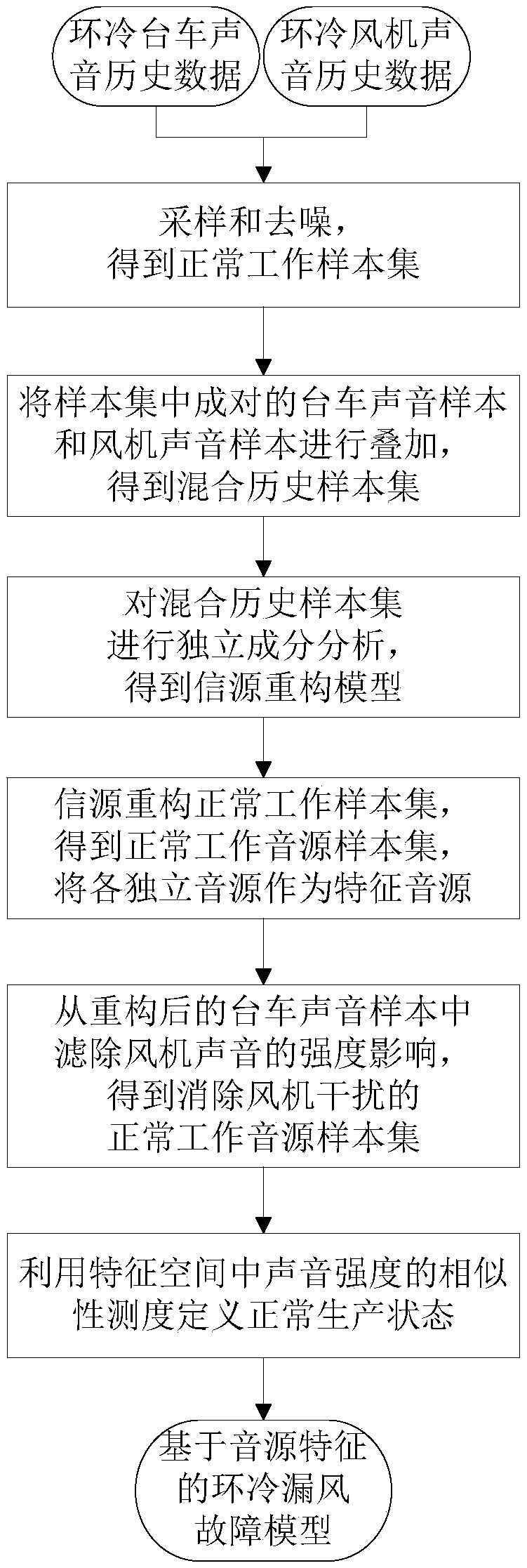

[0038] combine figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, a method for detecting air leakage rate of an annular cooler based on blind source separation and unilateral detection method is provided. Several first sound signal collectors are installed at the trolley of the annular cooler, and several second sound signal collectors are installed at the annular cooler fan. Acoustic signal collector, described method comprises the steps:

[0039] Including installing a plurality of first sound signal collectors at the trolley of the annular cooler, and installing a plurality of second sound signal collectors at the annular cooling fan, the method includes the following steps:

[0040] Step 1: Collect the sound data of the trolley and the sound data of the fan under normal working conditions, and obtain the sound samples of the trolley and the sound samples of the fan. The sound samples of the trolley and the sound samples of the fan correspond to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com