Anti-falling water-stop converter

A converter and water-stop technology, applied in couplings, textiles and papermaking, other washing machines, etc., can solve the problems of inconvenient operation, high manufacturing cost, loss, etc., to eliminate potential safety hazards, avoid serious waste, and be easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

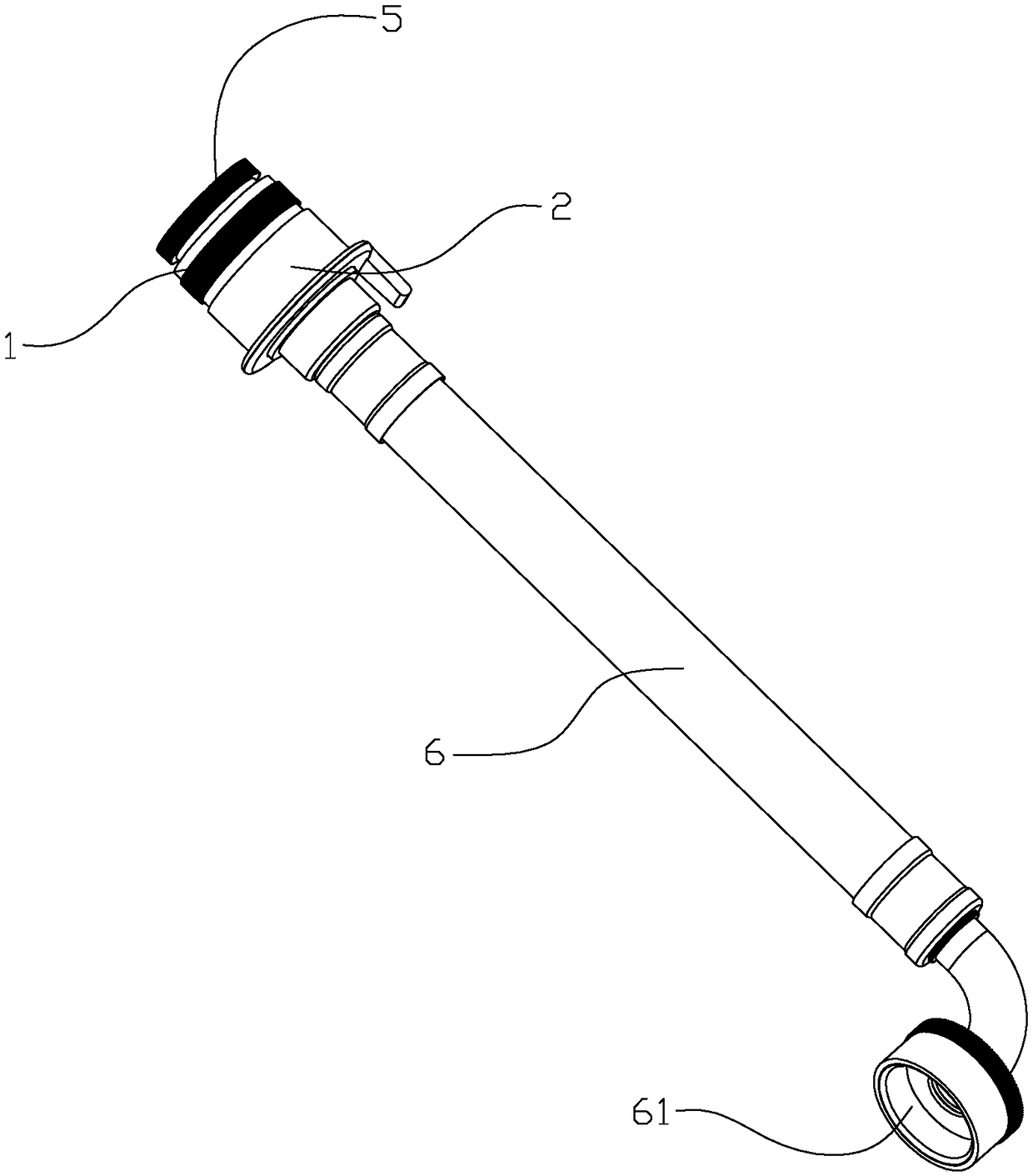

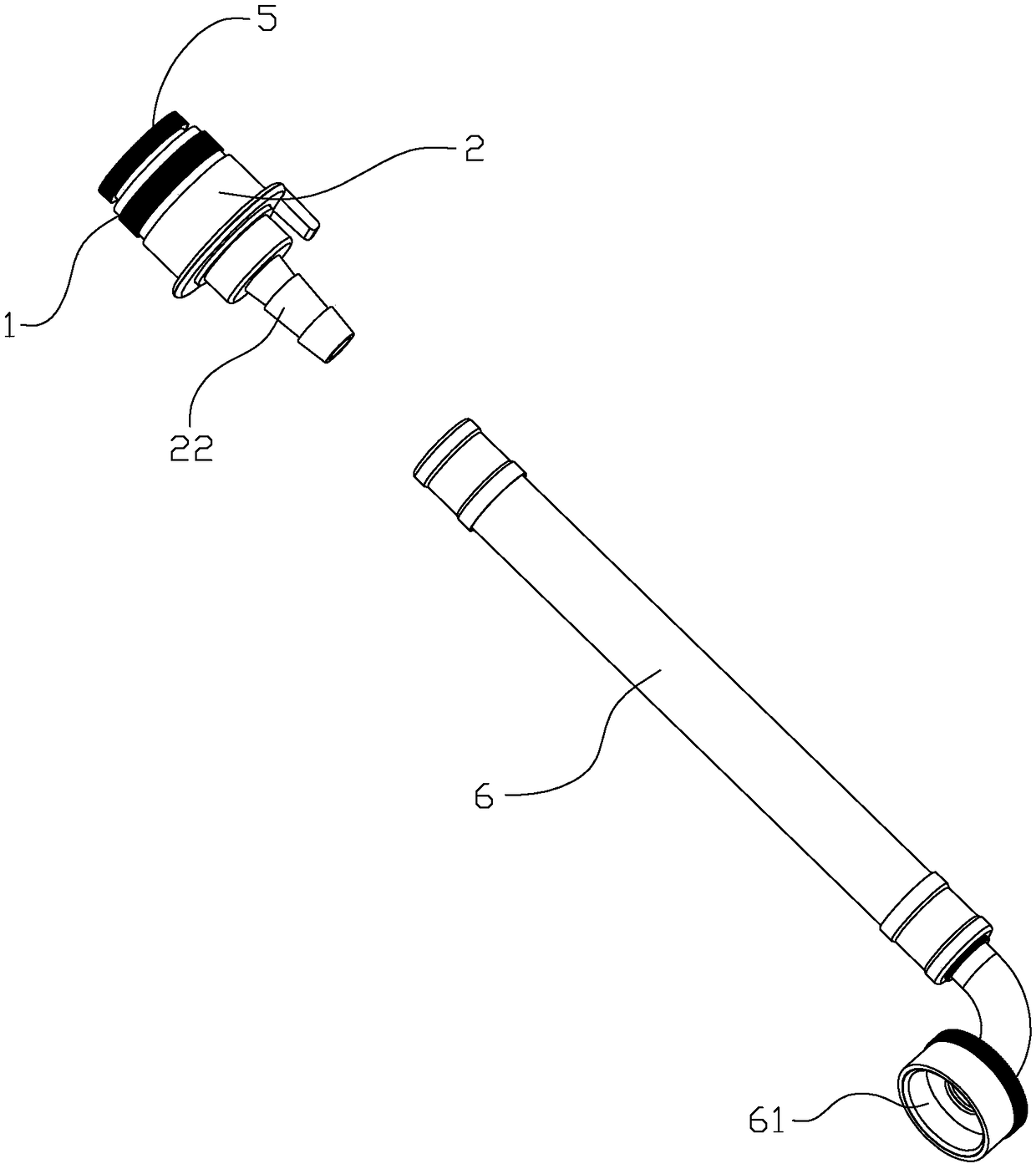

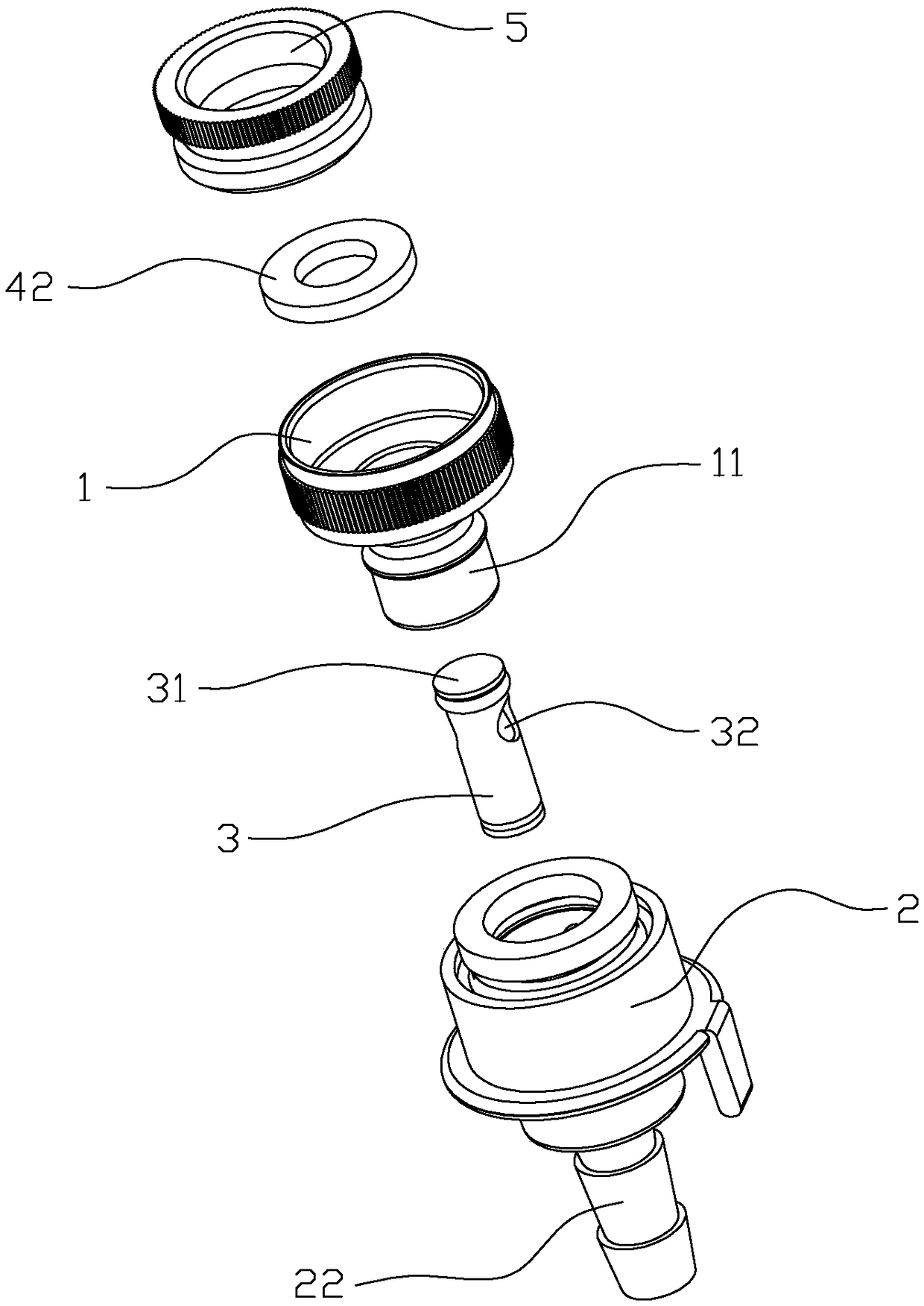

[0018] refer to Figure 1 to Figure 4 , a detachment-proof water converter, including an adapter seat 1 and a quick joint 2, the lower end of the adapter seat 1 is provided with a water outlet 11, and the quick joint 2 is connected to the water outlet 11, so The lower end of the water outlet nozzle 11 is provided with a water outlet hole, the adapter seat 1 is provided with a piston inner core 3 that is movably inserted in the water outlet hole, and the upper end of the piston inner core 3 is provided with a water outlet hole that is compatible with the water outlet hole. Cooperate with the sealed plug head 31, the lower part of the piston inner core 3 is a hollow pipe body and the outer peripheral wall is provided with a water hole 32, and the quick joint 2 is provided with a stopper that abuts against the lower end of the piston inner core 3 Block 21, under the restriction of the block 21, the water hole 32 is located inside the adapter seat 1 and communicates with the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com