Spring resetting mechanism for electric actuator

A technology of spring return mechanism and electric actuator, applied in the direction of engine components, spring/shock absorber, coil spring, etc., can solve problems such as power failure, valve out of control, brake motor inoperability, etc., to reduce operational risks and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

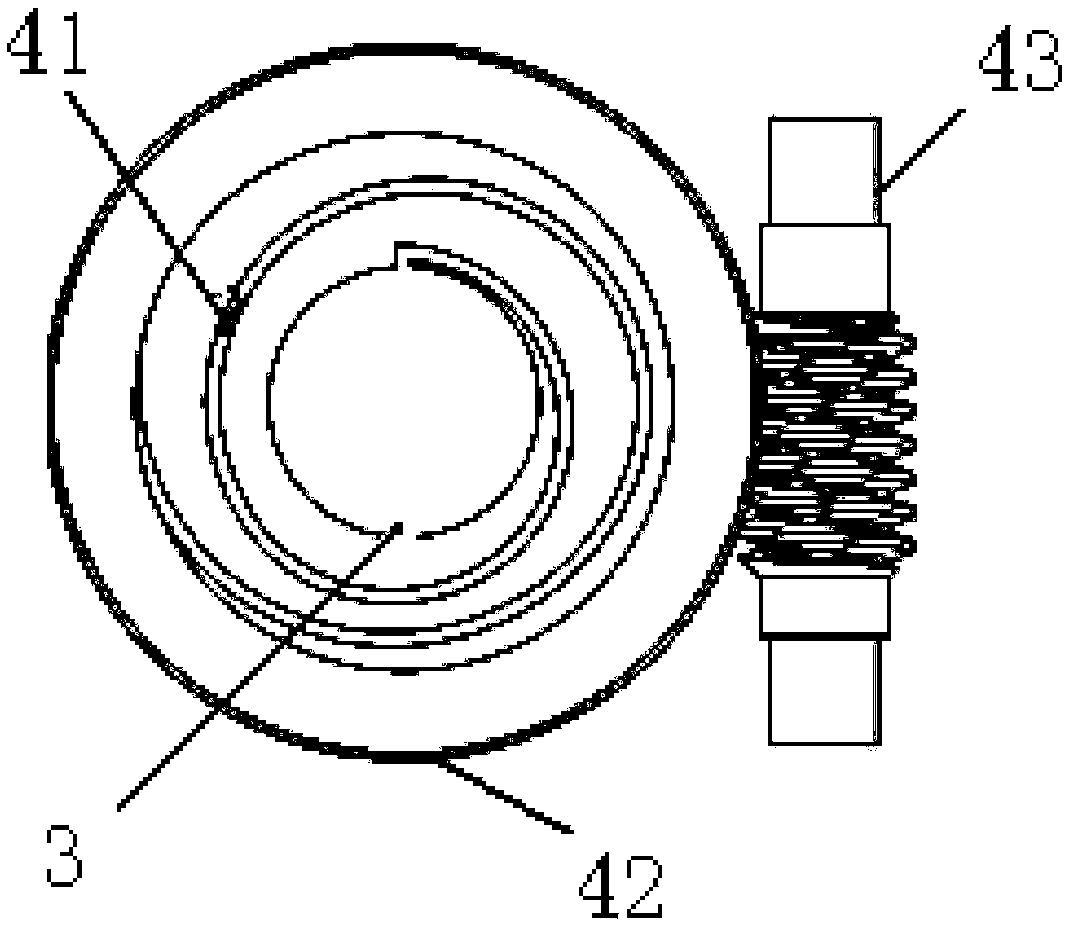

[0014] Such as figure 1 As shown, the spring return mechanism for the electric actuator of this embodiment includes a main shaft 3, a scroll spring 41, a turbine ring 42, and a worm screw 43 that cooperate with the valve stem for transmission. The main shaft 3 is sleeved in the scroll spring 41, and the scroll The spring 41 is sleeved in the turbine ring 42, the inner starting end of the scroll spring 41 is fixedly connected with the outer wall of the main shaft 3, the outer end of the scroll spring 41 is fixedly connected with the inner wall of the turbine ring 42, and the worm 43 is fixedly connected with the inner wall of the turbine ring 42. The outer sides of the ring 42 are meshed so that when the main shaft 3 rotates, the scroll spring 41 can be driven to store energy. When the worm 43 rotates, the turbine ring 42 can be driven to rotate to drive the scroll spring 41 to preload.

Embodiment 2

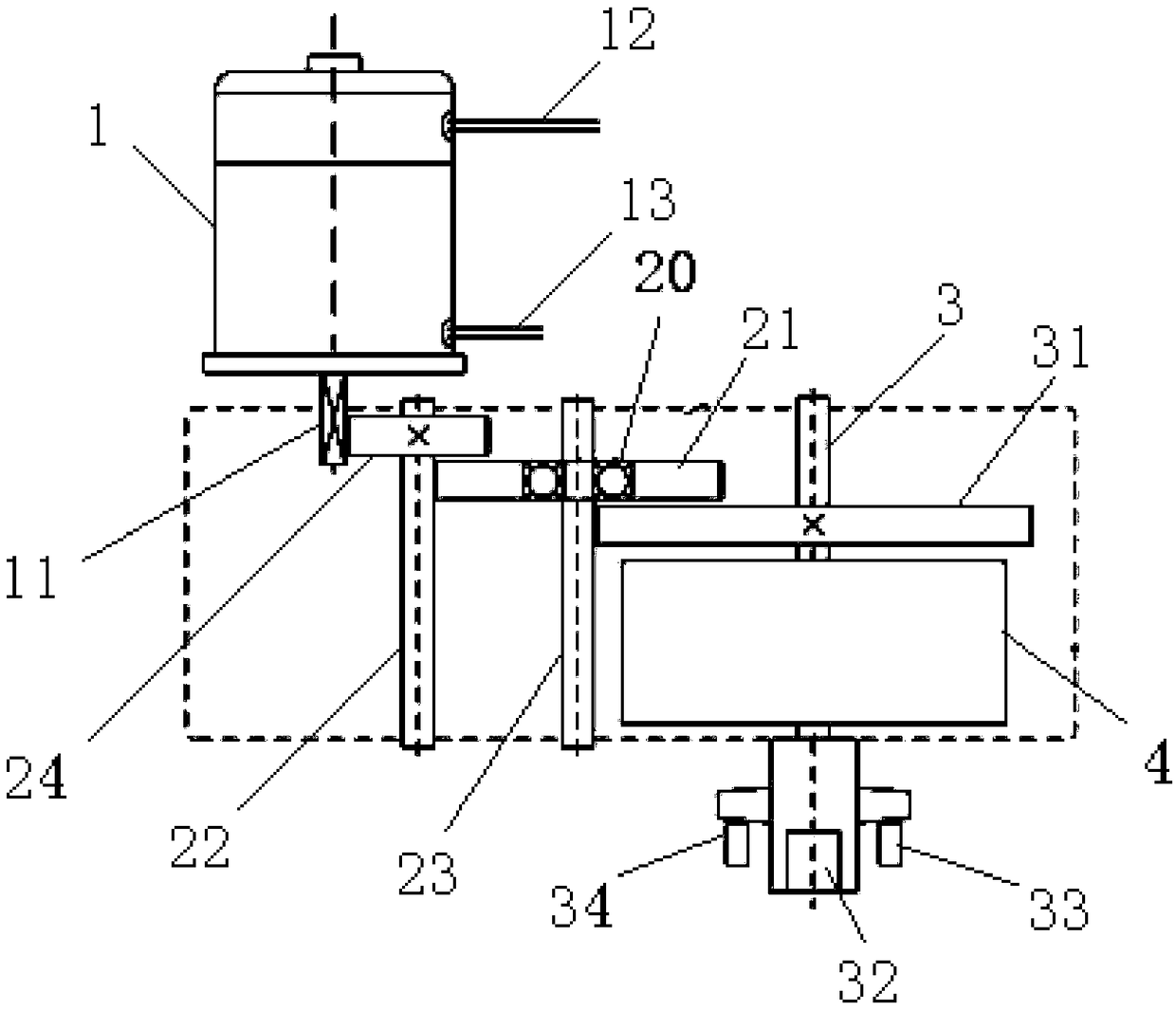

[0016] Such as figure 2 As shown, an electric actuator applying the spring return mechanism of Embodiment 1 includes a spring return mechanism 4 composed of a main shaft 3, a scroll spring 41, a turbine ring 42, and a worm 43, and also includes a brake motor 1, a one-way transmission mechanism, the one-way transmission mechanism includes a first transmission shaft 22, a second transmission shaft 23, a first gear 24, and an overrunning clutch. 23 through the one-way bearing 21 and the first transmission shaft 22 transmission and cooperation, and the first transmission shaft 22 is meshed with the outer ring 21 of the overrunning clutch 2, and the second transmission shaft 23 is fixedly connected with the inner ring 20 of the overrunning clutch 2, so that The brake motor 1 can drive the second drive shaft 23 to rotate; the spring return mechanism 4 also includes a second gear 31, a left limit bolt 34 and a right limit bolt 33 for limiting the rotation angle of the main shaft 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com