Building outer eave special-shaped decoration piece anti-wind-pressure structure system and construction method

A decorative sheet, wind pressure resistance technology, applied in building structure, building, roof and other directions, can solve the problem of high probability of cracking of welds at the connection between steel keel and steel structure, inability to effectively limit the swing range of special-shaped decorative sheets, and special-shaped decorative sheets. The limitation of swing amplitude is not obvious, so as to achieve the effect of low material cost, high construction efficiency and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

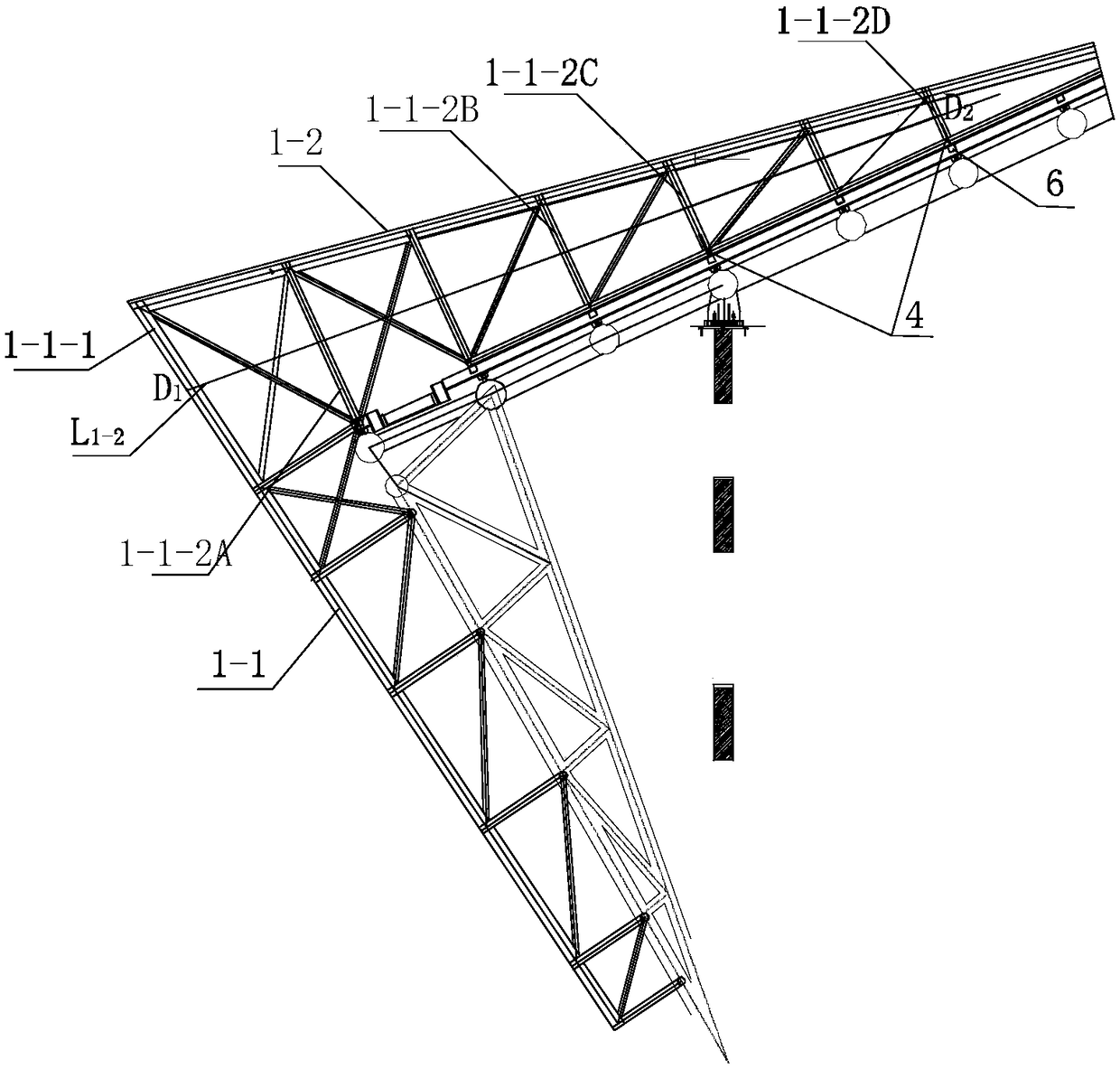

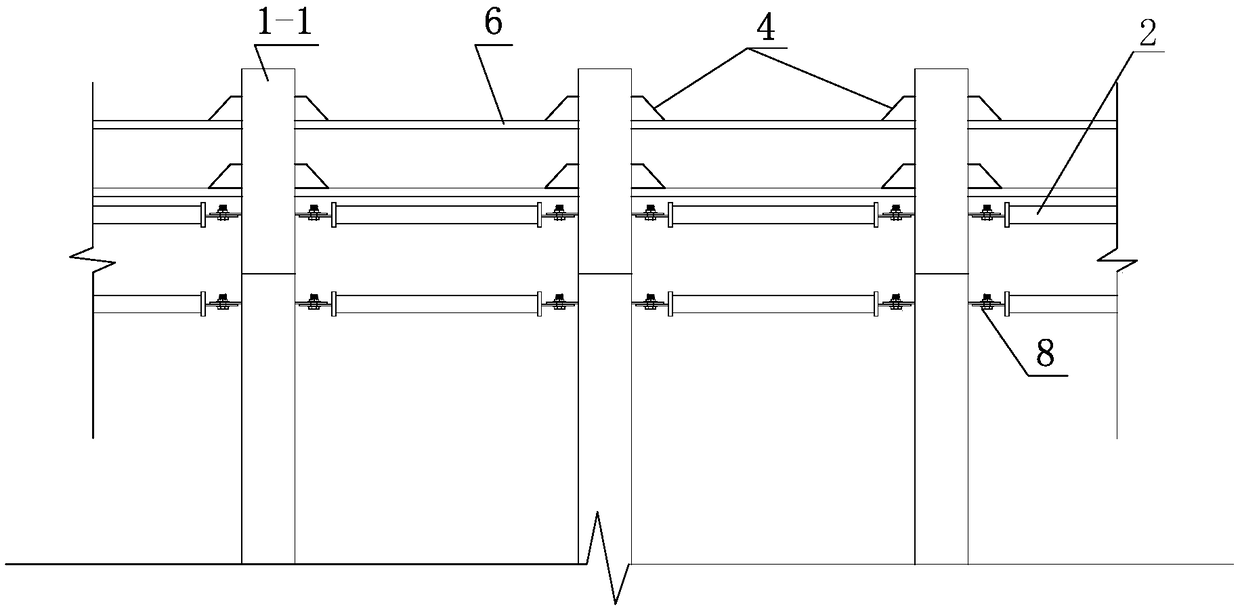

[0041] see Figure 1-Figure 8 , the building outer eaves special-shaped decorative sheet wind pressure resistant construction system, including the outer eaves metal curtain wall, oval roof 7, roof keel purlin 6, a plurality of special-shaped decorative sheets composed of decorative sheet keels 1-1 and decorative sheet panels 1-2 . The special-shaped decorative pieces are evenly distributed on the elliptical roof and the metal curtain wall of the outer eaves in an elliptical ring, and parallel support rods 2 are fixed between two adjacent special-shaped decorative pieces through connectors 5 and fasteners. The connectors in the adjacent special-shaped decorative sheet intervals at both ends of the long axis and the short axis of the shaped r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com