Crusher screen with double-sided slotted steel plate

A pulverizer, steel plate technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of not having the function of material crushing, not having the interference of the circulation layer, occupying the effective screening area, etc., to increase the shearing opportunity, Effect of reducing hole connection area and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

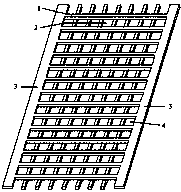

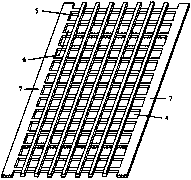

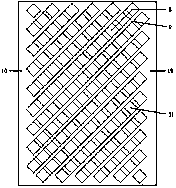

[0025] The hole shapes of the double-sided slotted hole screen include: triangular holes, square holes, elongated holes, rhombus holes, regular hexagonal holes and round holes. The slotting methods of double-sided slotting screen with holes include: parallel slotting and non-parallel slotting with the width of the steel plate. The slotting shapes of the double-sided slotting screen with holes are: linear slotting and broken line slotting. exist figure 1 , first reserve the width of the front edge (3), and then determine the width of the parallel straight front groove (2) parallel to the width of the steel plate and the width of the parallel straight front groove edge (1). The value range of the width of (1) is preferably between 3 / 5 and 1 / 3 of the width of the parallel straight front groove (2). According to the width of the parallel straight front groove (2), the diameter of the milling cutter is selected to be the same as its width. Then start to open the parallel straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com