Gasket hoop

A gasket and clamp technology, applied in the field of fixed support devices, can solve the problems that the clamp performance cannot meet aviation and aerospace standards, oil resistance, acid and alkali corrosion resistance, high temperature resistance, and traditional rubber pads have poor wear resistance and other problems. , to facilitate the replacement of composite materials, reduce maintenance and repair costs, and achieve significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

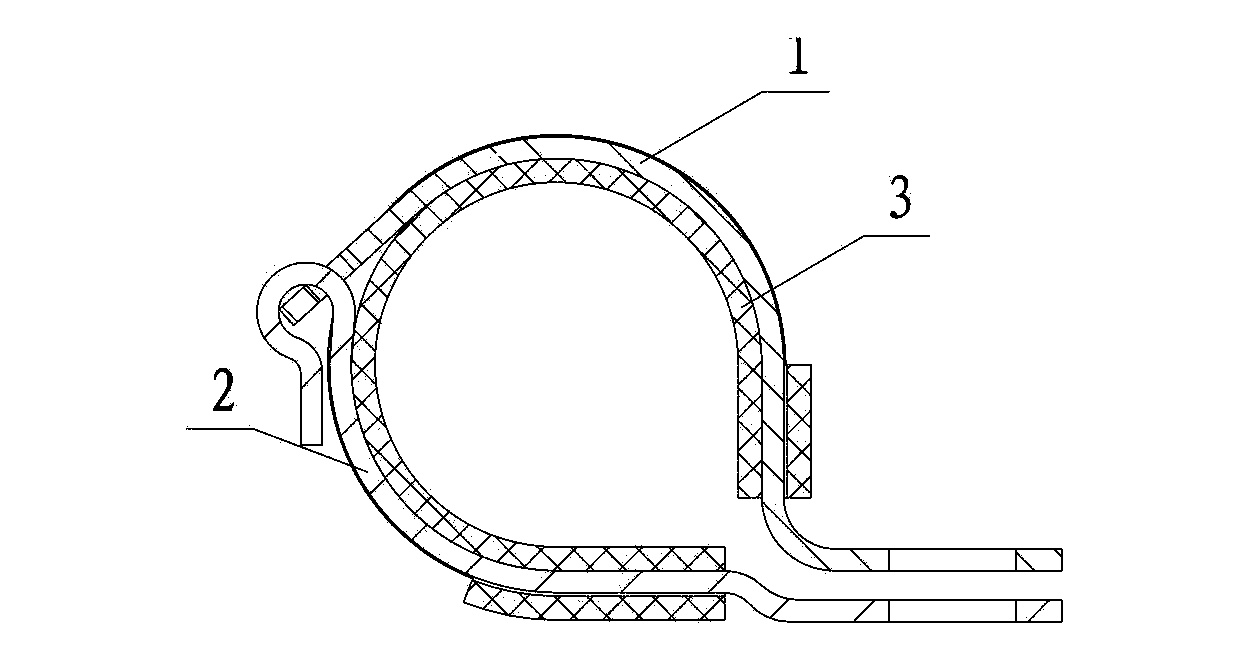

[0028] The specific embodiment of the present invention is shown in the accompanying drawings, the liner clamp is composed of a metal upper frame 1, a metal lower frame 2 and a composite material liner 3; it is characterized in that the metal upper frame 1 and the metal lower frame 2 phase connection; the two ends of the composite material liner 3 are processed with skeleton sleeves 3.1; the two skeleton sleeves 3.1 are respectively set on the metal upper frame 1 and the metal lower frame 2, and the composite material liner 3 is installed on the metal upper frame 1 and the metal lower frame 2. The inner side of the metal lower frame 2.

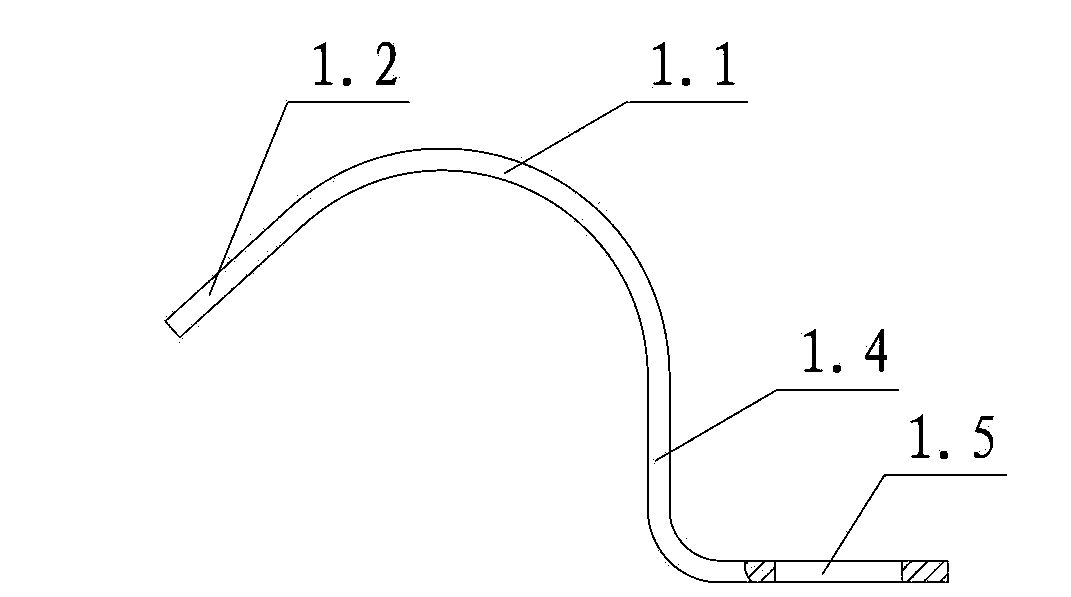

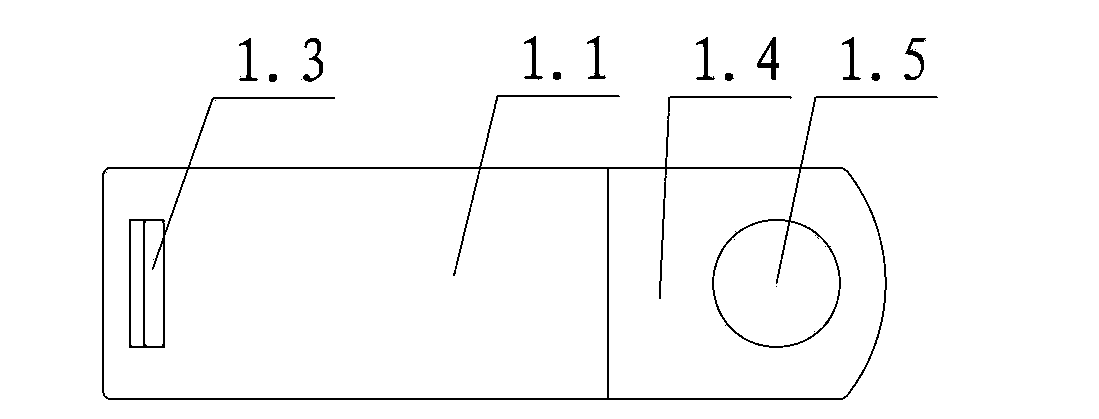

[0029] The metal upper frame 1 is a strip-shaped metal plate, its main body is a 1 / 3 arc 1.1, and one end of the 1 / 3 arc 1.1 has a straight line extension 1.2, and a closed square groove 1.3 is processed at the end of the straight line extension 1.2; The other end of 1 / 3 circular arc 1.1 has linear extension plate 1.4, and linear extension pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com