Controller wire throwing structure integrating EMC module

A controller and filter module technology, applied in electrical components, gaskets/seals, sealed enclosures, etc., can solve the problems of occupying the controller, inconvenient installation, complicated design, etc., to eliminate and differential mode interference, easy installation and disassembly, Easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

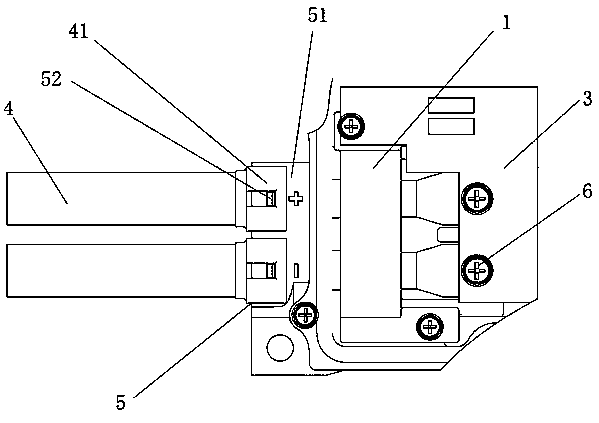

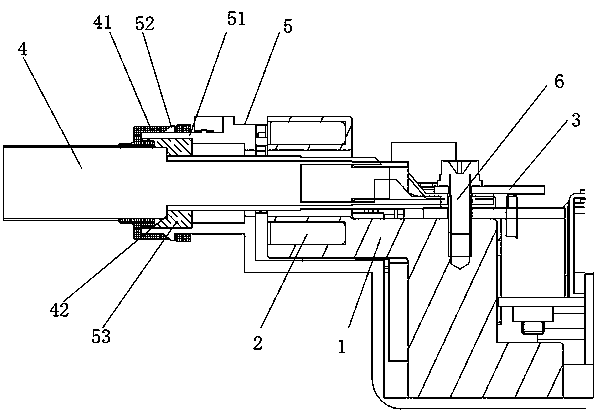

[0022] Such as figure 1 with 2 As shown, the controller wire-pulling structure of the integrated EMC module disclosed in the present invention includes a magnetic ring fixing seat 1, and a vertical magnetic ring 2 is fixed inside the front end of the magnetic ring fixing seat 1 (the number of magnetic rings is one or Multiple, this embodiment uses only one magnetic ring), the rear end is fixed with the filter module 3, the front end of the magnetic ring holder 2 is fixed with the plug structure 5 of the high-voltage bus 4, and the magnetic ring holder 1 is also provided with a through Passing through the through hole in the center of the magnetic ring 2, the front end of the through hole is connected to the plug-in structure 5, the back end leads to the filter module 3, and the high-voltage busbar 4 overlaps with the filter module 3 through the plug-in structure 5 and the through hole in turn. The filter module 3 is a circuit board structure, and the filter module 3 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com