Inner hole detecting device of workpiece and using method thereof, and detection assembly line

A detection device and workpiece technology, applied in the direction of mechanical diameter measurement, sorting, etc., can solve problems such as the inability to automatically classify workpieces, and achieve the effects of simple and reliable structure, low production and use costs, and fast material distribution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

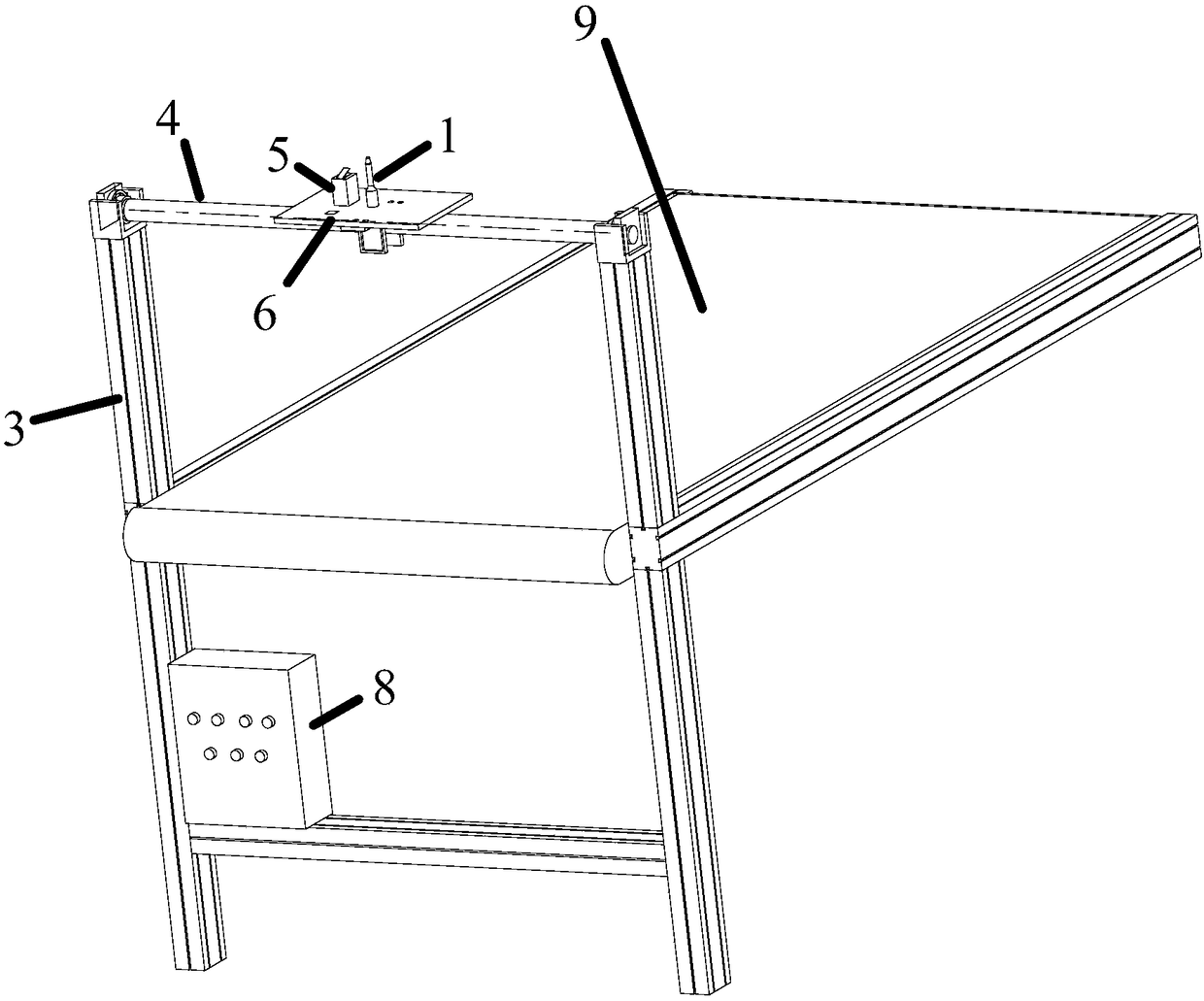

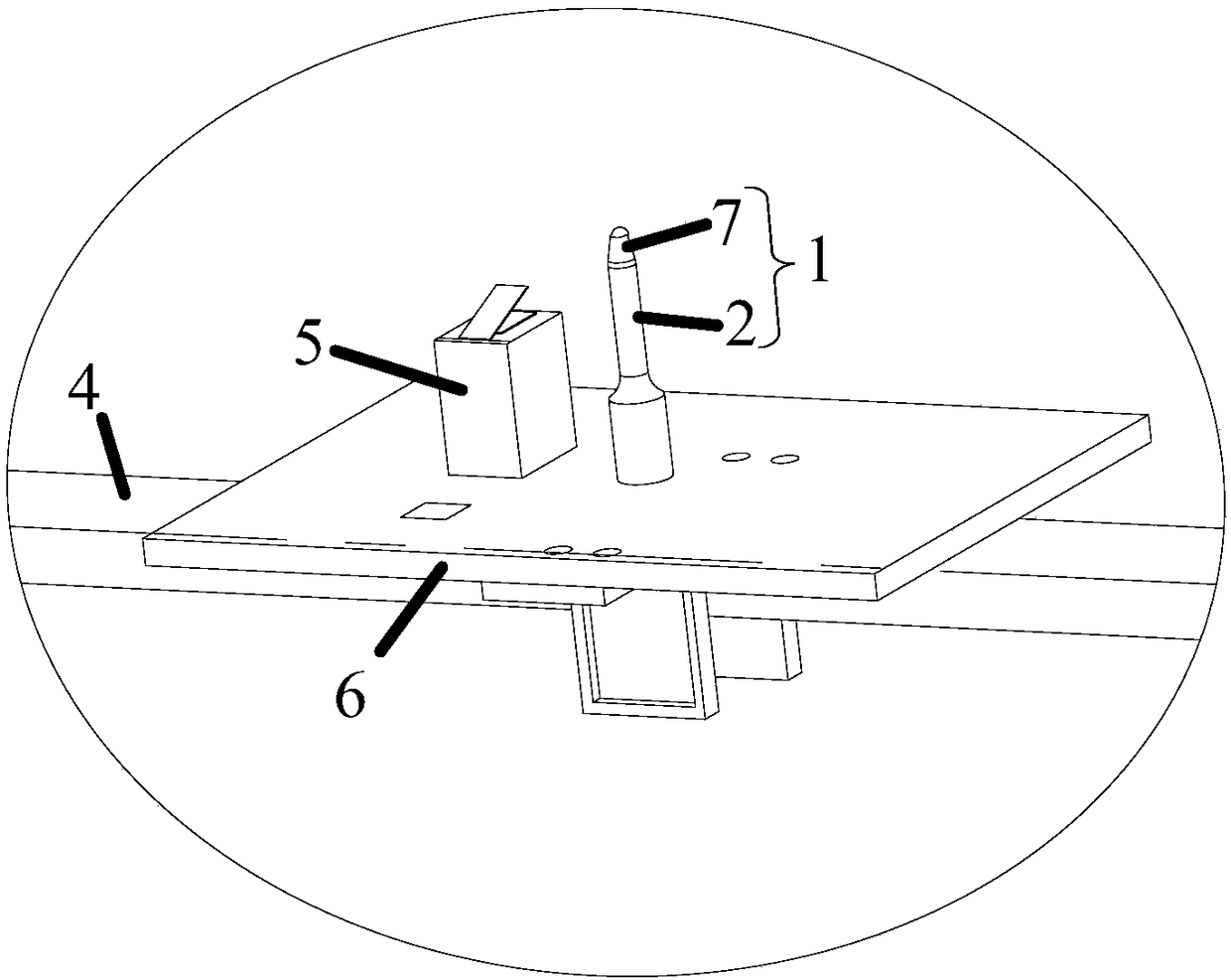

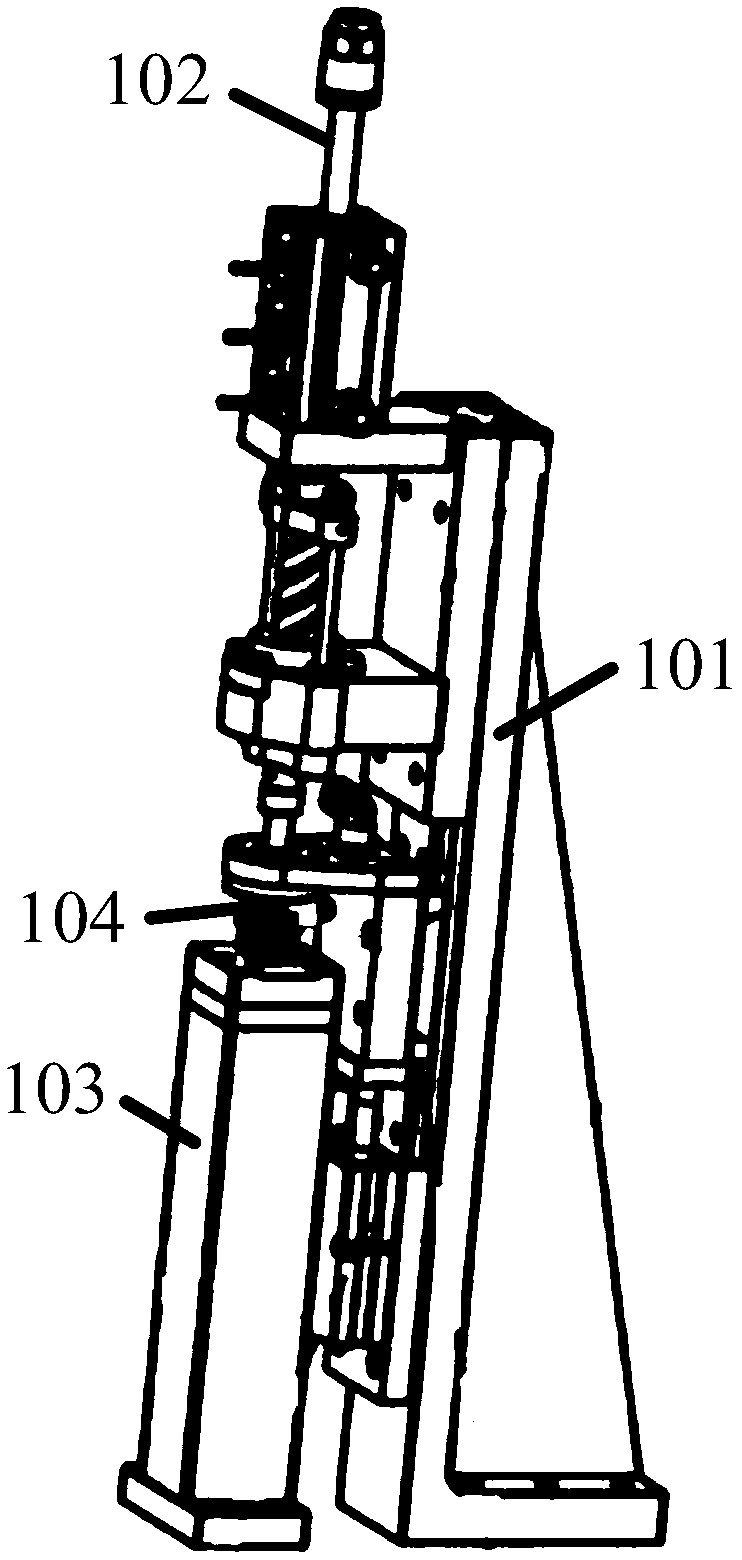

[0042] This embodiment provides a detection line for detecting whether the inner cavity diameter of the fan blade shaft sleeve is qualified, such as figure 1 The detection assembly line shown includes a workpiece inner hole detection device with a material distribution function, a feeding mechanism and a discharging mechanism for transferring the qualified workpiece to the next station. The feeding mechanism is a manipulator, and the manipulator grabs the air. The blade shaft sleeve is moved towards the workpiece inner hole detection device with a constant force, and the discharge mechanism is a conveyor belt 9 arranged in the qualified area of the workpiece, and the qualified blade shaft sleeve is transported to the next station. Such as figure 1 and figure 2 The workpiece inner hole detection device shown includes:

[0043] Sorting mechanism, which includes a support frame 3 arranged between the workpiece waste area and the workpiece qualified area, and a rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com