A method to improve the quality of copper-zinc-tin-sulfur thin film of photoelectrochemical water splitting photocathode

A copper-zinc-tin-sulfur, photoelectrochemical technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve problems such as adsorption of dense impurity particle layers, and achieve the effects of low cost, inhibition of high-temperature decomposition reaction, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

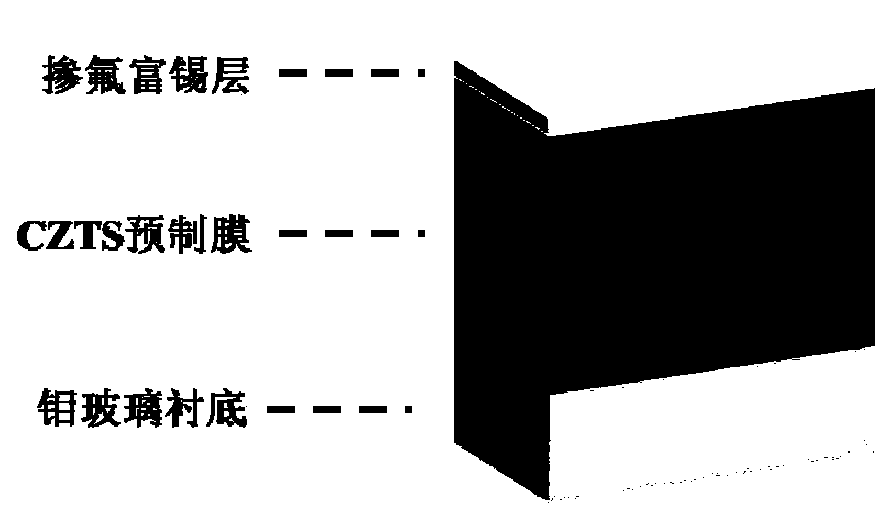

[0041] Embodiment 1: the preparation of copper-zinc-tin-sulfur film

[0042] (1) Weigh 0.002mol of copper chloride, 0.001mol of zinc chloride, 0.001mol of stannous chloride and 0.007mol of thiourea into 10ml of dimethylformamide solution, stir and dissolve to form copper zinc tin sulfur Precursor solution;

[0043] (2) Drop the copper-zinc-tin-sulfur precursor solution onto the molybdenum glass substrate for spin-coating, the spin-coating speed is set to 3000 rpm, the spin-coating time is 30 seconds, and 4 layers are spin-coated;

[0044] (3) Add 0.2mmol tin acetate and 0.002mmol sodium fluoride to a mixed solution of 1.9ml ethylene glycol methyl ether and 0.1ml ethanolamine, stir and dissolve to form a fluorine-doped tin-rich solution, and spin-coat this solution onto copper-zinc-tin-sulfur For the upper layer of the prefabricated film, the spin-coating speed is set to 2000 rpm, the spin-coating time is 20 seconds, and one layer is spin-coated;

[0045] (4) Place the above ...

Embodiment 2

[0048] Embodiment 2: the preparation of copper-zinc-tin-sulfur film

[0049] (1) Weigh 0.006 mole of copper acetate, 0.004 mole of zinc acetate, 0.033 mole of stannous acetate and 0.026 mole of thiourea and join in 10ml dimethylformamide, stir and dissolve to form a copper zinc tin sulfur precursor solution;

[0050] (2) Drop the copper-zinc-tin-sulfur precursor solution onto the molybdenum glass substrate, set the spin-coating speed to 3500 rpm, spin-coating time is 40 seconds, and spin-coat 6 layers;

[0051] (3) Add 0.4mmol tin nitrate and 0.008mmol sodium fluoride to 1.9ml ethylene glycol methyl ether and 0.1ml ethanolamine mixed solution, stir and dissolve to form a fluorine-doped tin-rich solution, and spin-coat this solution onto copper-zinc-tin-sulfur For the upper layer of the prefabricated film, the spin-coating speed is set to 3000 rpm, the spin-coating time is 30 seconds, and 2 layers are spin-coated.

[0052] (4) Place the above film on a hot plate at 300°C for p...

Embodiment 3

[0055] Embodiment 3: the preparation of copper-zinc-tin-sulfur film

[0056] (1) Weigh 0.008 mole of copper acetate, 0.005 mole of zinc acetate, 0.006 mole of stannous acetate and 0.025 mole of thiourea into 10ml dimethylformamide, stir and dissolve to form a copper zinc tin sulfur precursor solution;

[0057] (2) Drop the copper-zinc-tin-sulfur precursor solution onto the molybdenum glass substrate, set the spin-coating speed to 4000 rpm, spin-coating time is 40 seconds, and spin-coat 8 layers;

[0058] (3) Add 0.8mmol of tin nitrate and 0.024mmol of sodium fluoride to 1.9ml of ethylene glycol methyl ether and 0.1ml of ethanolamine mixed solution, stir and dissolve to form a fluorine-doped tin-rich solution, and spin-coat this solution onto copper-zinc-tin-sulfur The upper layer of the prefabricated film, the spin-coating speed is set to 3500 rpm, the spin-coating time is 35 seconds, and three layers are spin-coated;

[0059] (4) Place the above film on a hot plate at 400°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com