Preparation method of jun porcelain artware of avalokitesvara

A technology of Guanyin Jun porcelain and its production method, applied in decorative arts, clay products, applications, etc., can solve the problems of low treasure rate, easy cracking, low Jun porcelain treasure rate, etc., and achieve the effect of high yield and good bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

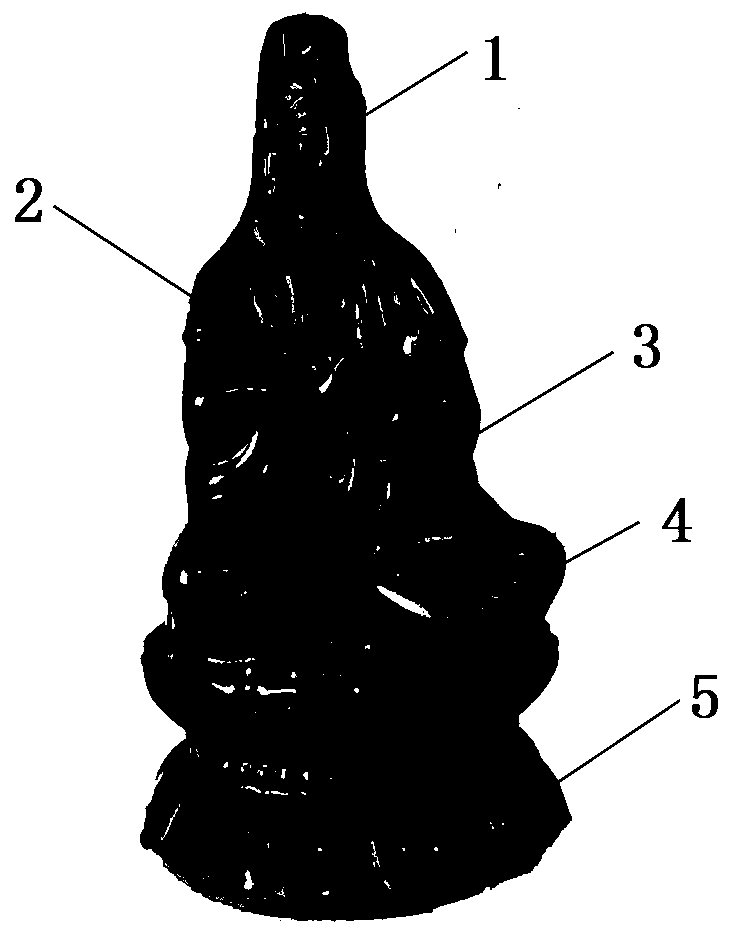

[0021] Such as figure 1 As shown, the invention discloses a method for making Guanyin Jun porcelain handicraft, comprising the following steps:

[0022] Step 1. Carve the model; divide the whole handicraft into multiple parts to carve separately, including head 1, hands, legs 4, main body and lotus stand 5, in which head 1 carves hair, facial features and hat; hands include left hand and The right hand 2 is carved separately; the palm of the left hand faces upward, the porcelain vase 3 is placed in the palm, and the left hand is placed on the leg; the four fingers of the right hand 2 are folded together, and the wrist and thumb are placed on the chest ; Carve hem and folds on the main body; the legs of the legs 4 sit cross-legged;

[0023] Step 2, making a mould; making plaster moulds, respectively, from the parts carved in step 1;

[0024] Step 3, select pottery clay; the pottery clay includes the following components: 60 parts of kaolin, 10 parts of sandstone, 10 parts of ...

Embodiment 2

[0033] Such as figure 1 Shown, a kind of preparation method of Guanyin Jun porcelain handicraft, comprises the following steps:

[0034] Step 1. Carve the model; divide the whole handicraft into multiple parts to carve separately, including head 1, hands, legs 4, main body and lotus stand 5, in which head 1 carves hair, facial features and hat; hands include left hand and The right hand 2 is carved separately; the palm of the left hand faces upward, the porcelain vase 3 is placed in the palm, and the left hand is placed on the leg; the four fingers of the right hand 2 are folded together, and the wrist and thumb are placed on the chest ; Carve hem and folds on the main body; the legs of the legs 4 sit cross-legged;

[0035] Step 2, making a mould; making plaster moulds, respectively, from the parts carved in step 1;

[0036] Step 3, select pottery clay; said pottery clay includes the following components: 70 parts of kaolin, 9 parts of sandstone, 9 parts of lead powder, 10 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com