Intelligent manufacturing equipment

A technology of intelligent manufacturing and equipment, applied in the field of intelligent manufacturing equipment, can solve problems such as unsmooth tapping of external threads, affecting thread quality, and consuming a lot of physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

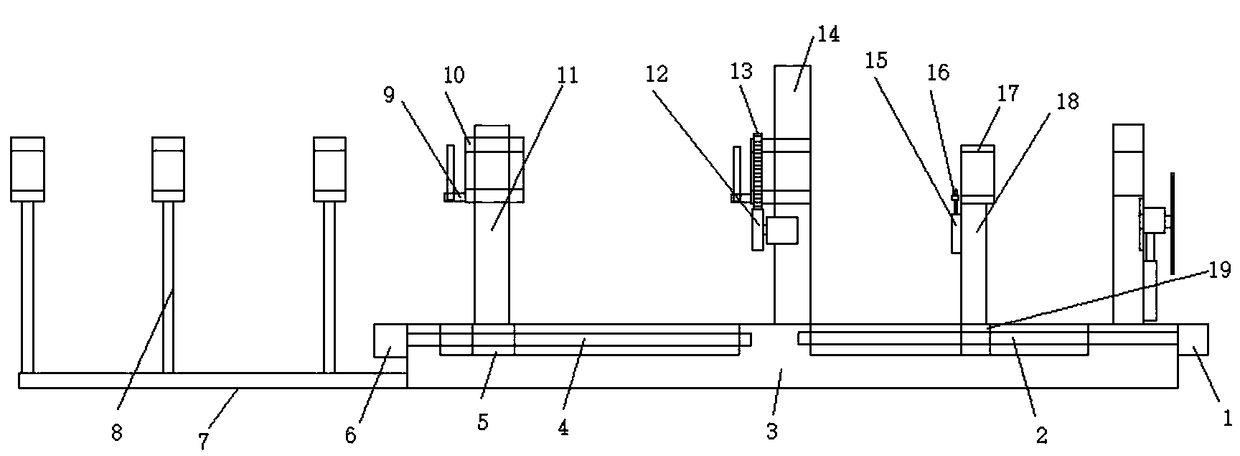

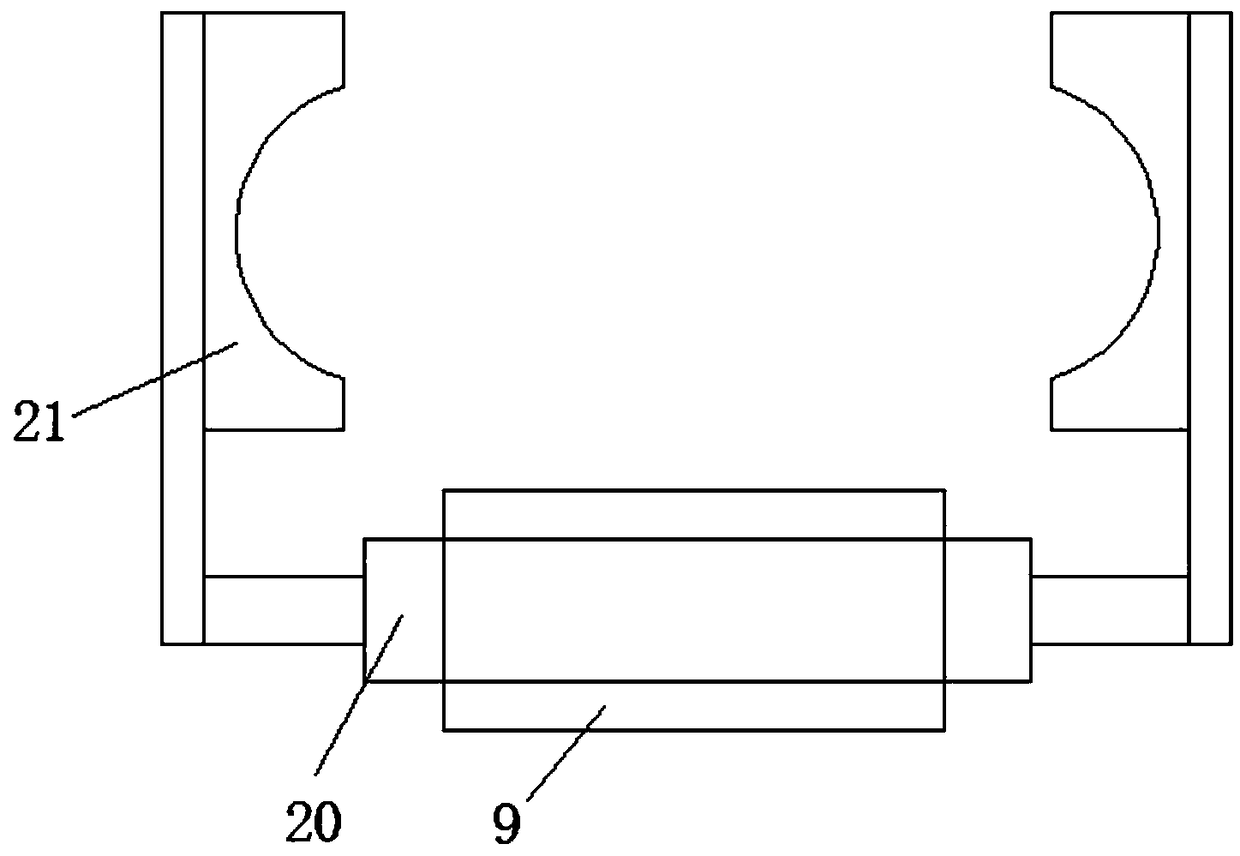

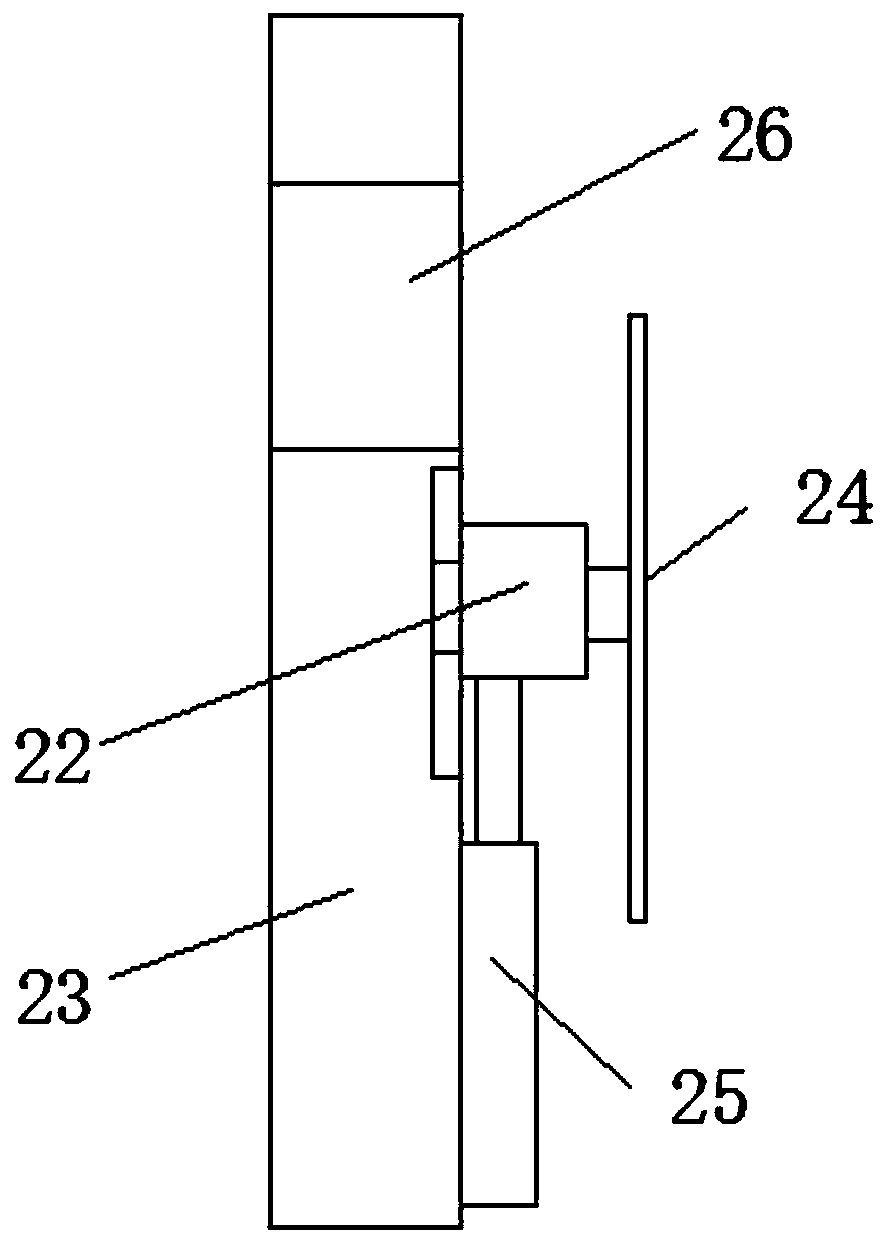

[0021] Embodiment: When in use, the metal column to be processed is placed on the auxiliary support frame 8 on the auxiliary support plate 7, and one end of the metal column passes through the rotating cylinder 10 on the first movable column 11 and extends to the fixed column 14. In the rotating cylinder 10, the controller controls the two piston rods of the double-headed cylinder 20 on the first movable column 11 to drive the two clamping blocks 21 to move to clamp and fix the metal column, and the second motor 6 drives the second The threaded rod 4 rotates, and the second threaded rod 4 is threadedly connected with the second sliding block 5, driving the second sliding block 5 to slide in the second sliding groove, so that one end of the metal column passes through the rotating cylinder 10 on the fixed column 14 and extends to In the guide cylinder 17, the two piston rods of the double-headed cylinder 20 on the first movable column 11 drive the two clamping blocks 21 to move. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com