Anchoring element for a plumbing fastener

A technology for anchoring elements and fixing components, applied in the field of sanitary facilities, can solve the problems of reducing the firmness and increasing the difficulty of cost and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

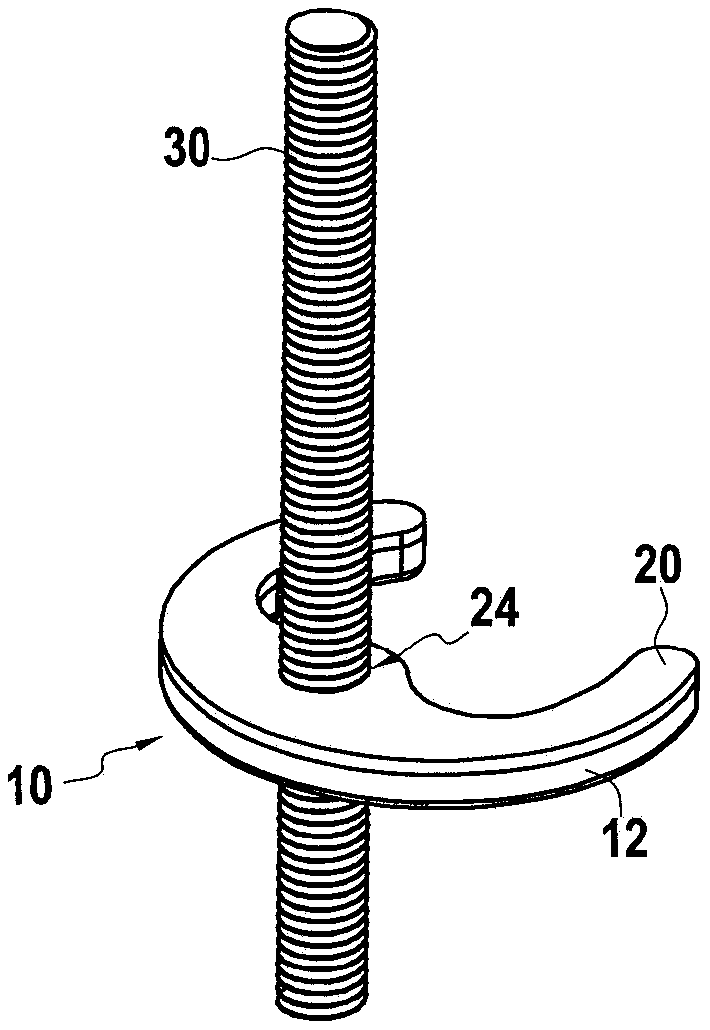

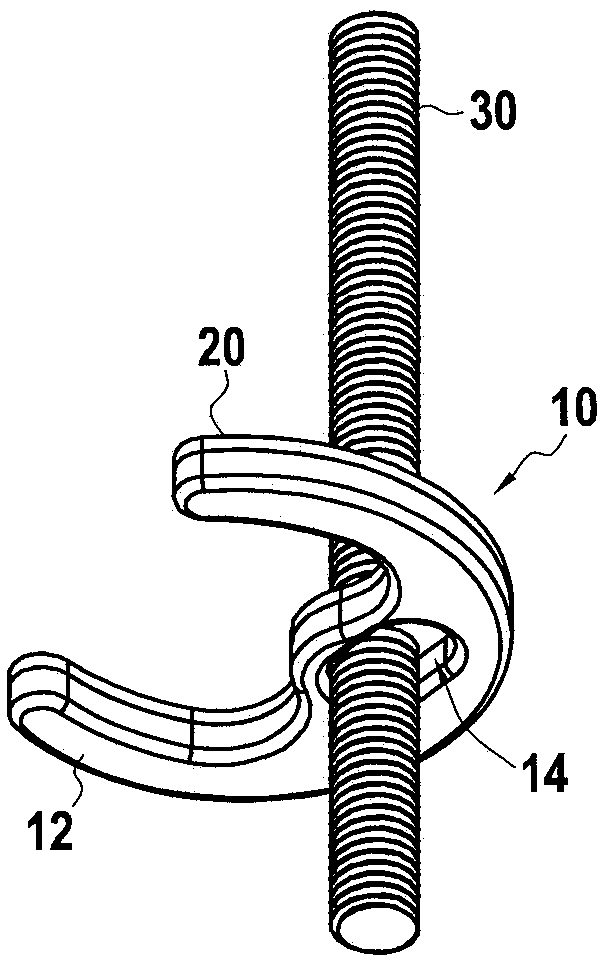

[0045] will refer to figure 1and 2 describe a first embodiment of an anchoring element for fixing a tap.

[0046] figure 1 Anchoring element 10 including base 12 is shown. The base 12 has a first through hole 14 . The first hole 14 allows a rod to be inserted, as described below. Here, the base 12 is generally C-shaped, U-shaped or horseshoe-shaped, having a central portion 16c and two arcuate arms 16a, 16b on either side of the central portion 16c. The two arms 16a, 16b and the central portion 16c lie substantially in the same main plane. The generally C-shape optimizes the support surface of the anchoring element while making it easy to pass the tap supply tube through the aperture of the mounting surface.

[0047] In this embodiment, the first hole 14 is provided in the central portion 16c.

[0048] The shape of the first hole 14 is configured such that the inclination angle of the rod can be changed. To achieve this, in this embodiment the first hole 14 is oblong. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com