Sputtering target

A technology of sputtering target and target structure, applied in the field of sputtering target, which can solve the problems of unsteady sputtering, adhesion of conductive film, damage of transparent conductor layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] Hereinafter, the results of confirmation experiments conducted to confirm the effectiveness of the invention of the present application will be described.

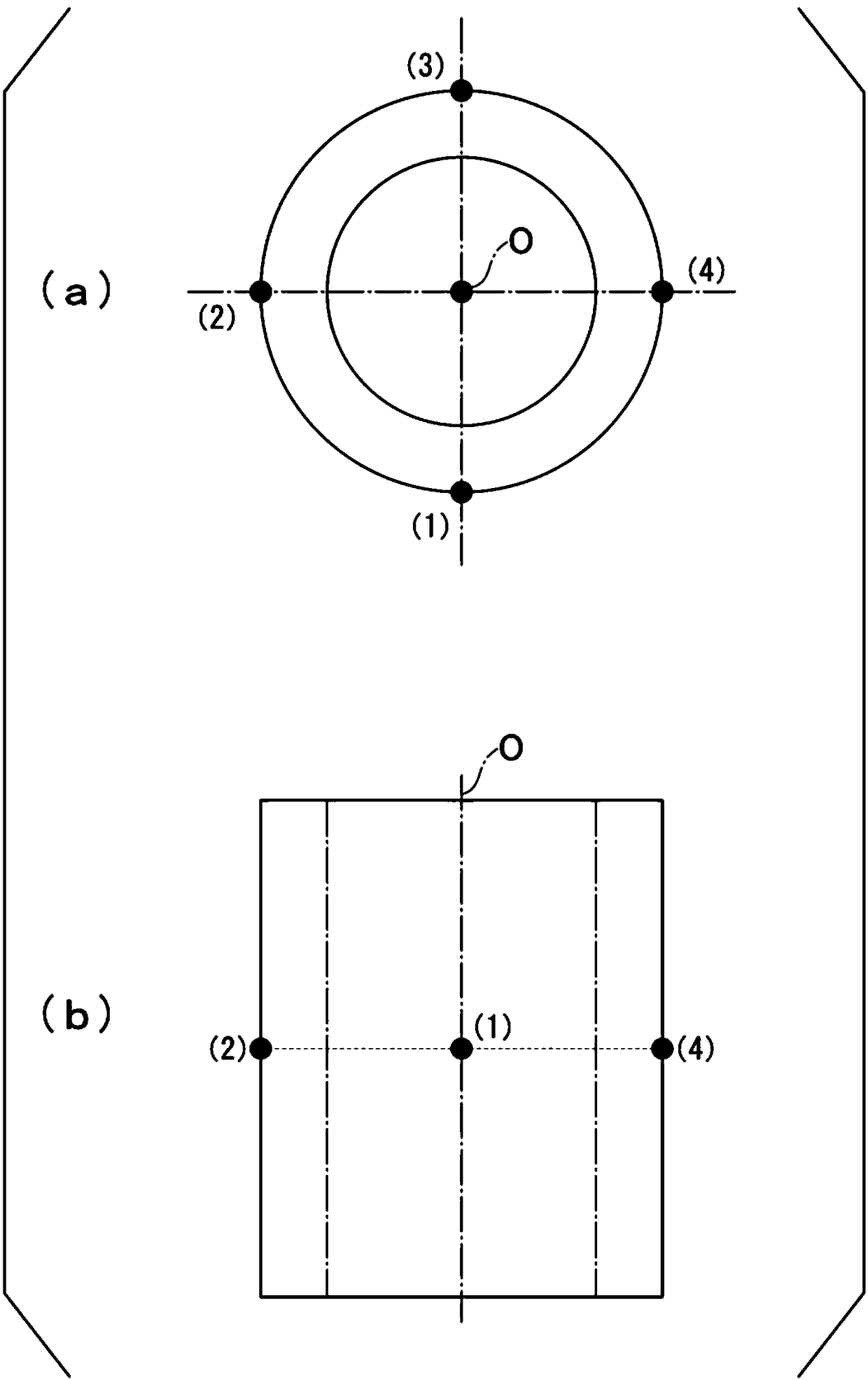

[0100] (sputtering target)

[0101] As raw material powders, metallic copper powder (purity: 99.9% by mass or more, average particle size is shown in Table 1), CuO powder (purity: 99% by mass or more, average particle size: 5 μm), Cu 2 O powder (purity: 99% by mass or more, average particle diameter: 3 μm).

[0102] These raw materials were weighed so as to become the molar ratio recorded in Table 1, and in the container of the ball mill device set as the Ar gas atmosphere, the raw materials weighed and zirconia balls (diameter: 5mm), and mixed for 3 hours.

[0103] After sieving the obtained raw material powder, it is filled in a hot-pressed flat plate and cylindrical shape molding die, at 200kgf / cm 2 At the sintering temperatures shown in Table 1, the flat plate shape was maintained for 3 hours and the cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com