Hollow fiber membrane module and method for producing the hollow fiber membrane module

A hollow fiber membrane and hollow technology, which is applied in the field of manufacturing hollow fiber membrane modules, can solve problems such as strength reduction and thermal deformation, and achieve the effect of inhibiting damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

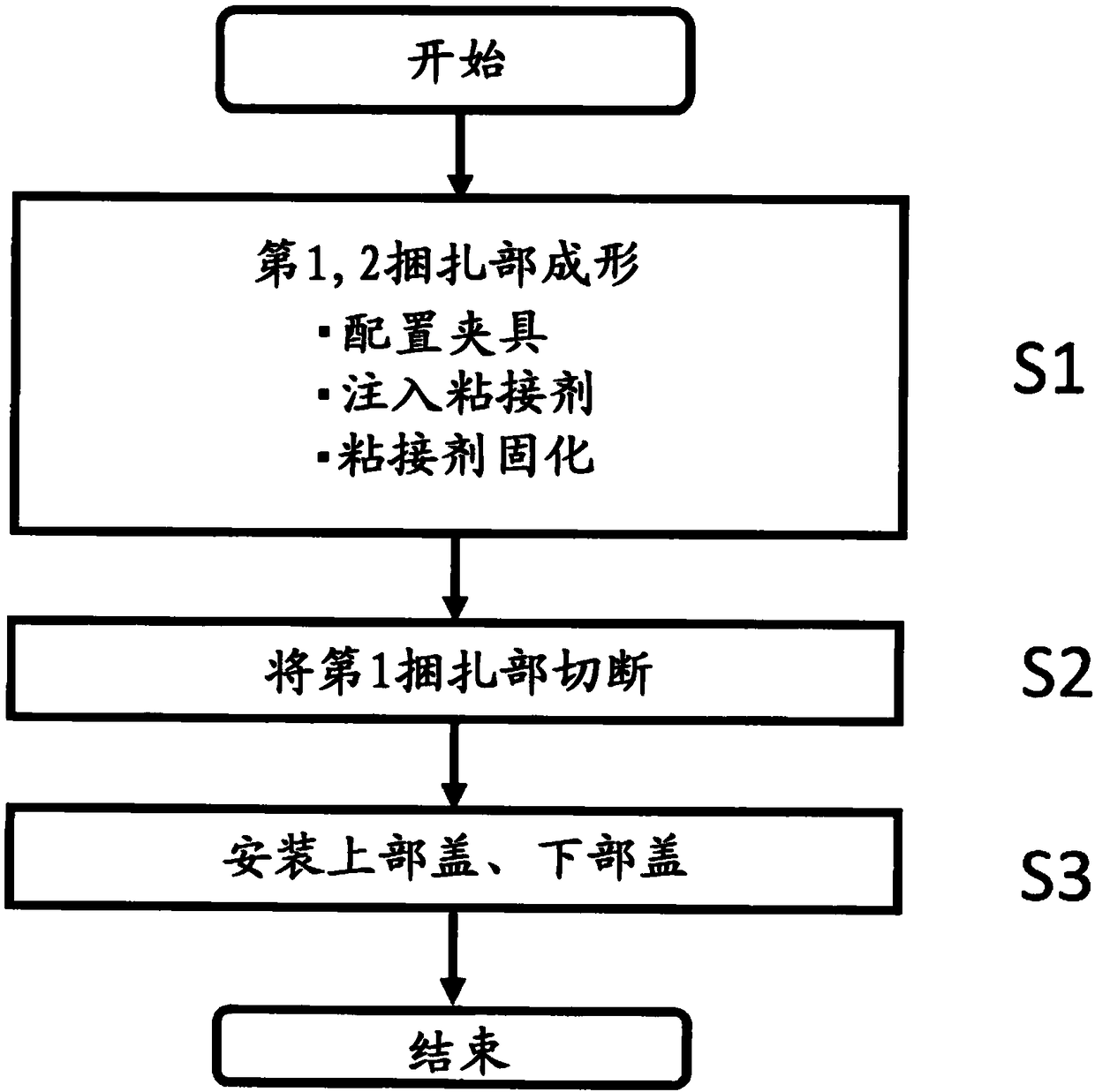

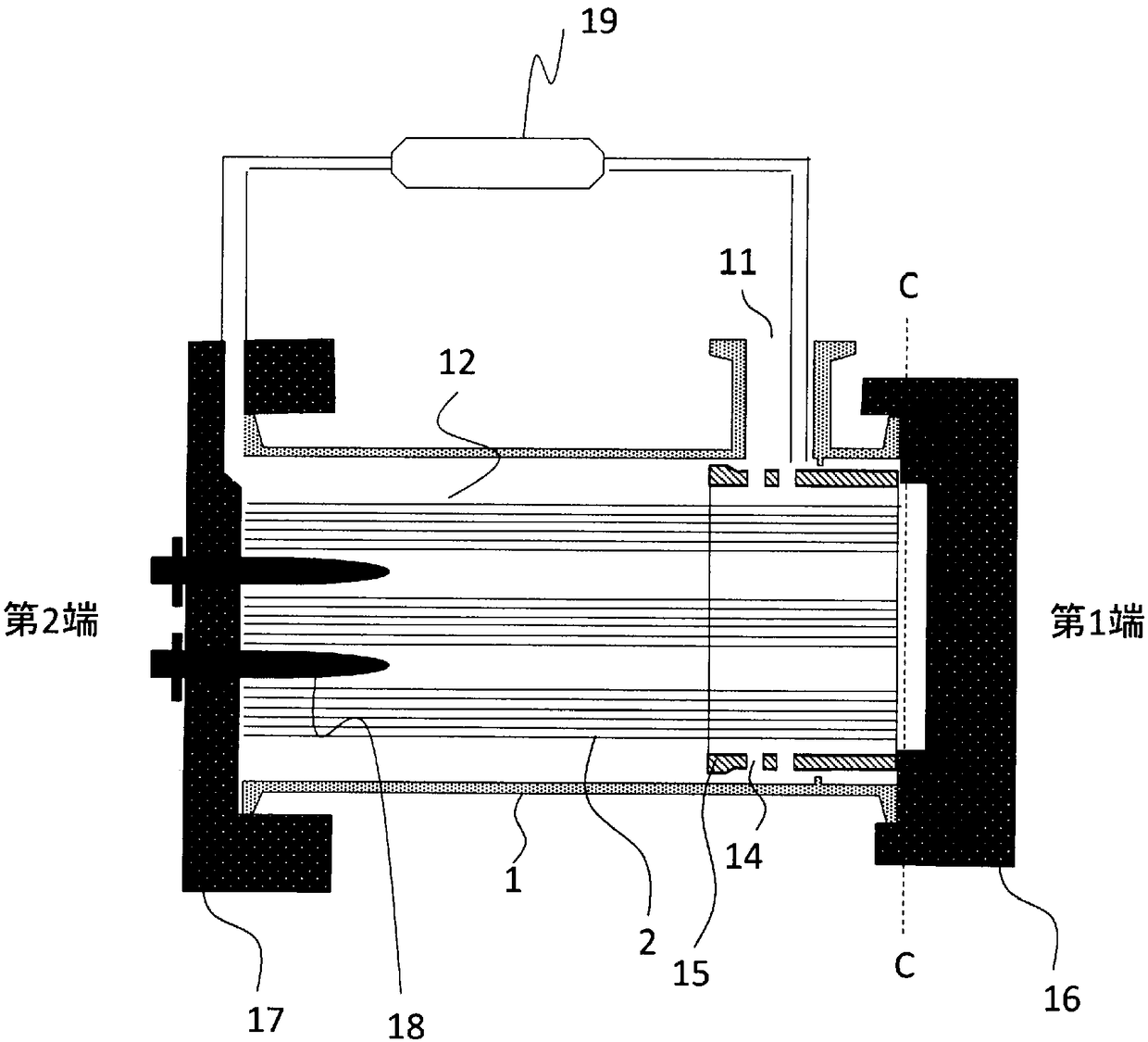

[0049] The structure of the hollow fiber membrane module according to the first embodiment of the present invention will be described with reference to the drawings. figure 1 It is a schematic longitudinal sectional view of an external pressure type hollow fiber membrane module 100A according to the first embodiment of the present invention.

[0050]

[0051]The hollow fiber membrane module 100A according to the first embodiment includes: a cylindrical case 1 having a first end and a second end in the height direction; The hollow fiber membrane bundle 12 of the plurality of hollow fiber membranes 2 whose ends on the second end side are closed; the first bundling part 3 for bundling the ends of the hollow fiber membranes 2 on the first end side; The second binding part 4 for binding the ends.

[0052] The cylindrical case 1 is composed of a hollow cylindrical case main body 1 , and upper covers 6 and lower covers 7 provided at both ends of the cylindrical case main body 1 . ...

no. 2 Embodiment approach

[0183] The structure of the hollow fiber membrane module 100B according to the second embodiment of the present invention will be described with reference to the drawings. Figure 4 It is a schematic vertical cross-sectional view of a hollow fiber membrane module 100B according to the second embodiment. In addition, regarding the structure of the hollow fiber membrane module 100B not mentioned below, the same structure as the hollow fiber membrane module 100A of the first embodiment can be applied. Members having the same functions as those described in the first embodiment are denoted by the same reference numerals and their descriptions are omitted.

[0184] In the filtration operation using the internal pressure type hollow fiber membrane module 100B according to the second embodiment, the filtrate enters from the filtrate inlet 21 and passes through the hollow fiber membrane 2 from the second end side of the second binding part 4 The hollow part is taken out from the filt...

no. 3 Embodiment approach

[0190] The structure of a hollow fiber membrane module 100C according to a third embodiment of the present invention will be described with reference to the drawings. Figure 5 It is a schematic vertical cross-sectional view of the first end side of the hollow fiber membrane module 100C according to the third embodiment. In addition, about the structure of 100 C of hollow fiber membrane modules which are not mentioned below, the same structure as 100 A of hollow fiber membrane modules of 1st Embodiment can be applied. Members having the same functions as those described in the first embodiment are denoted by the same reference numerals and their descriptions are omitted.

[0191] In the hollow fiber membrane module 100C according to the third embodiment, the first binding part 3 compresses the sealing material 25 and the sealing material 26 to be fixed to the second cylindrical case 15 and the upper cover 6 in a liquid-tight manner.

[0192] The second cylindrical case 15 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com