Equipment for installing head shell of battery

A technology for installing equipment and batteries, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as inconsistent beating strength, inconsistent size of lithium batteries, and improper installation of lithium batteries, etc., to achieve The effect of precise installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

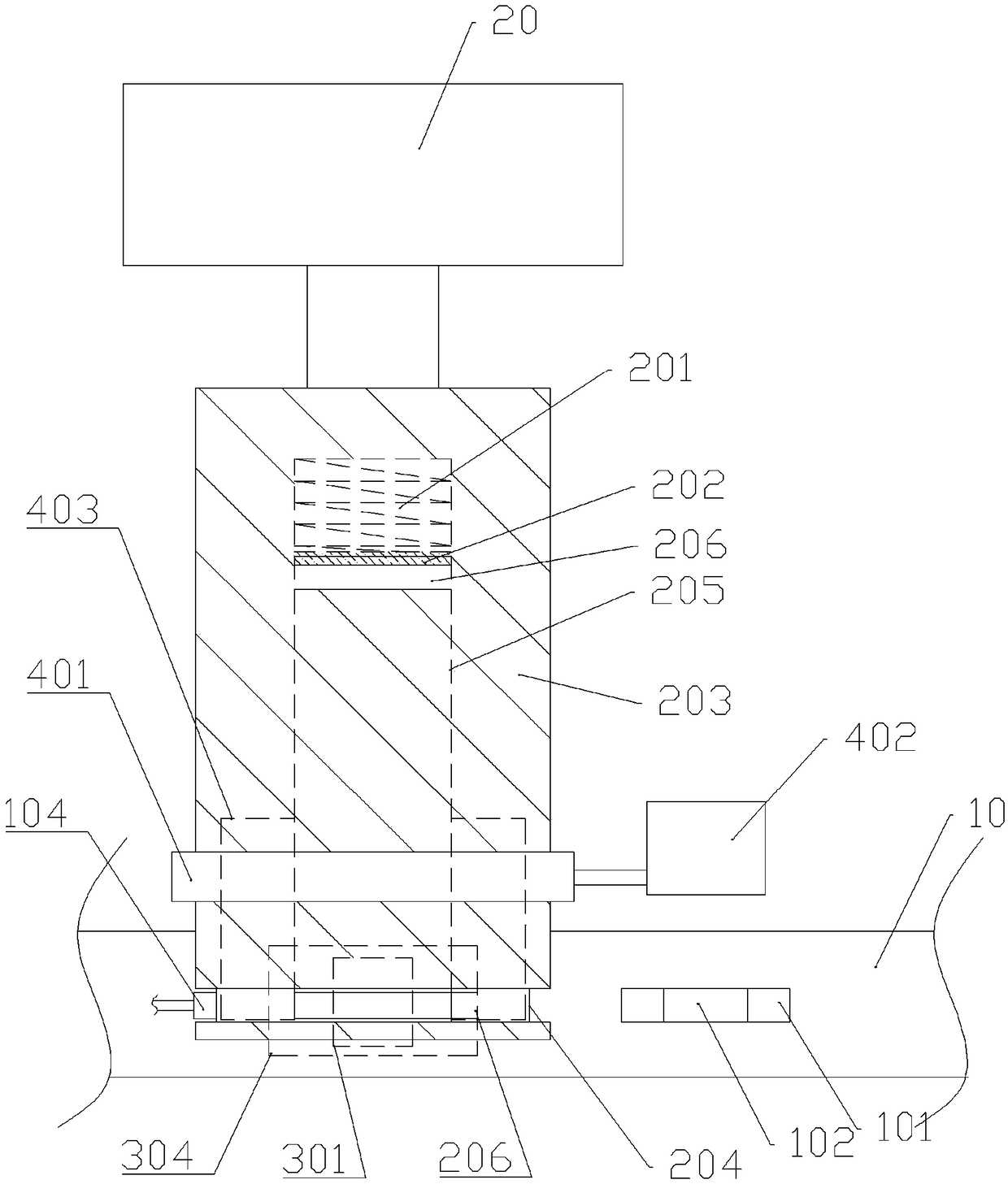

[0019] The reference signs in the drawings of the description include: conveyor belt 10, vertical through groove 101, through hole 102, lifting cylinder 103, support plate 104, motor 20, first spring 201, extrusion plate 202, transmission shaft 203, annular Slot 204, rectangular through slot 205, press port 206, feed port 206, limit block 301, third spring 303, fixed block 304, push rod 305, second spring 306, slide bar 307, press bar 308, installation ring 401, air pump 402, air bag 403, battery 50, head shell 60.

[0020] The embodiment is basically as attached figure 1 And attached figure 2 Shown: battery 50 head case 60 installation equipment, including conveyor belt 10, clamping mechanism, lifting cylinder 103, arc support plate 104, feeding mechanism and pressing mechanism, conveyor belt 10 is set horizontally, and conveyor belt 10 is provided with vertical The through groove 101; the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com