Parameter optimization method of power assembly mounting system used for heavy chassis

A powertrain and suspension system technology, applied in the direction of design optimization/simulation, electrical digital data processing, special data processing applications, etc., can solve the problems of complex vehicle driving conditions, limited layout space, harsh vibration environment, etc., to achieve Suitable for popularization and use, avoiding resonance problems, and improving the effect of vibration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

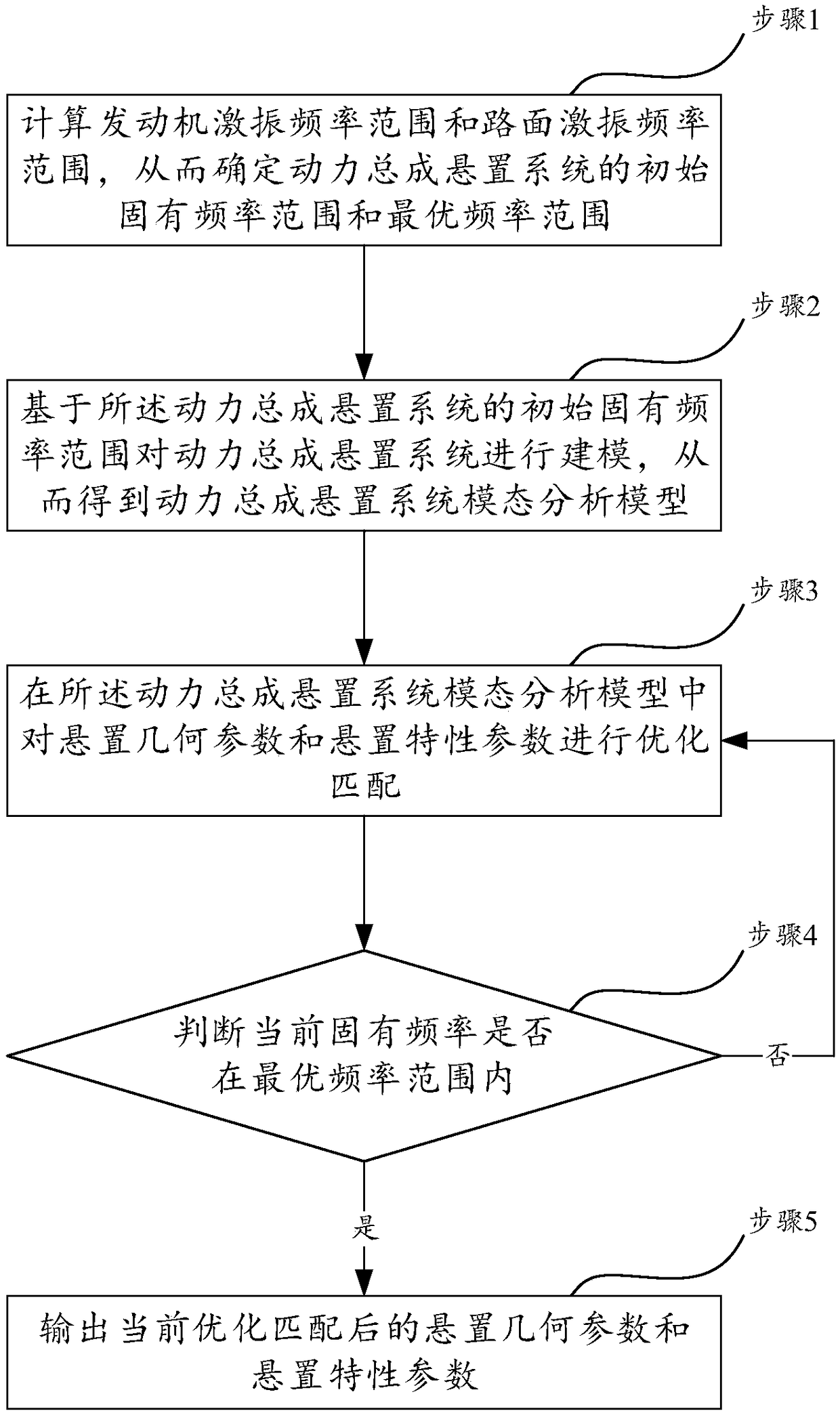

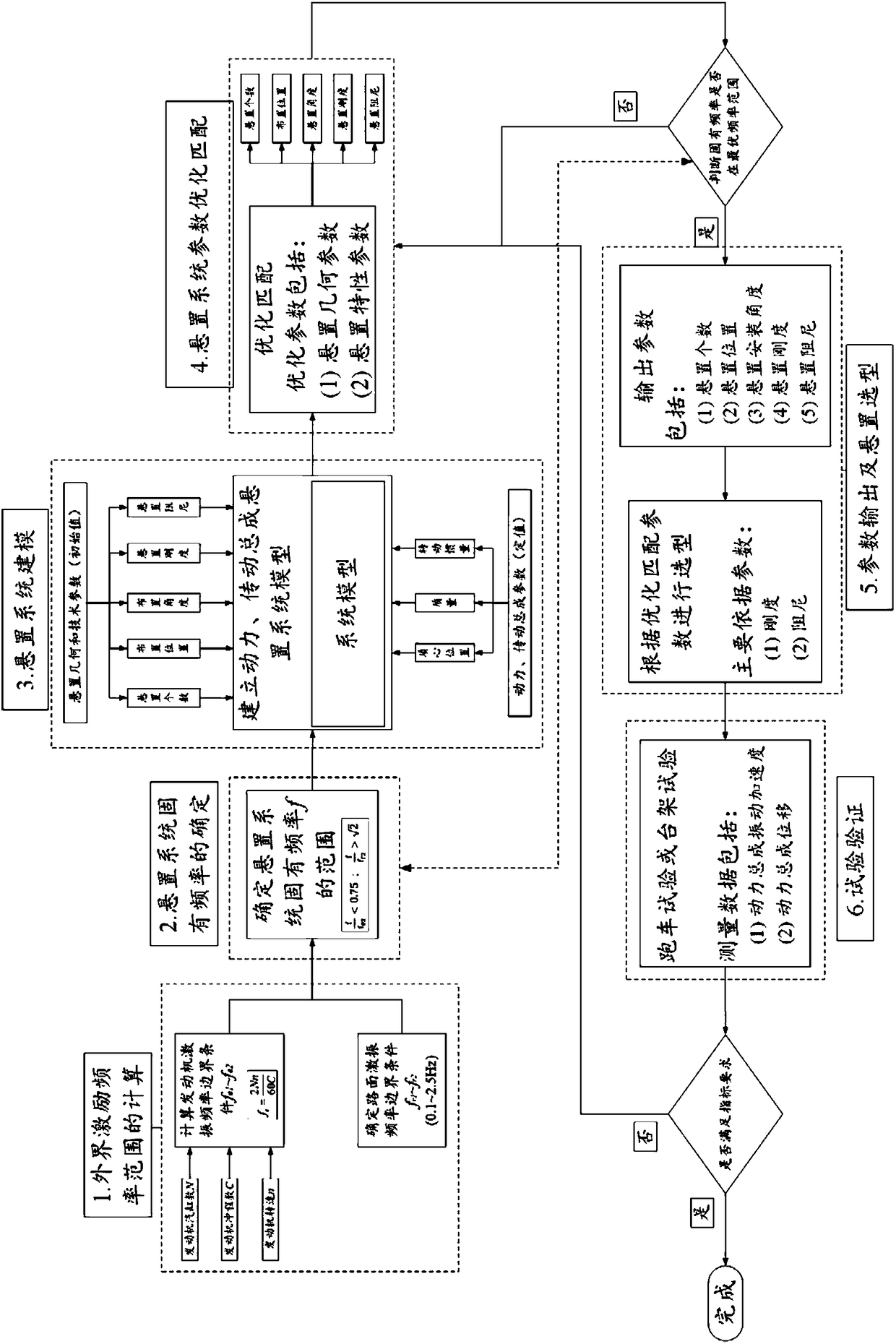

[0030] The parameter optimization method for the powertrain suspension system of the heavy-duty chassis according to the present invention will be explained and described in detail below in conjunction with the accompanying drawings.

[0031] Such as figure 1 , figure 2 As shown, the present invention specifically discloses a parameter optimization method for a powertrain suspension system of a heavy-duty chassis, in order to prevent resonance and play a damping role as the goal of suspension system optimization, the powertrain suspension system Considering the structural principle, basic knowledge of vibration, the function of the powertrain mount system, the mechanism of vibration reduction and other factors, so as to realize the parameter optimization of the powertrain mount system for heavy-duty chassis, specifically, the parameter optimization The method includes the following steps.

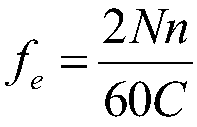

[0032] Step 1. Considering that the excitation source of the powertrain mount system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com