Automatic oil lubrication device of bearing of wheel or pulley

An oil lubricating and pulley technology, applied in the field of automatic oil lubricating devices for wheels and pulley bearings, can solve the problems of long downtime, difficult control of grease replenishment quality, grease extrusion, etc. The effect of downtime risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

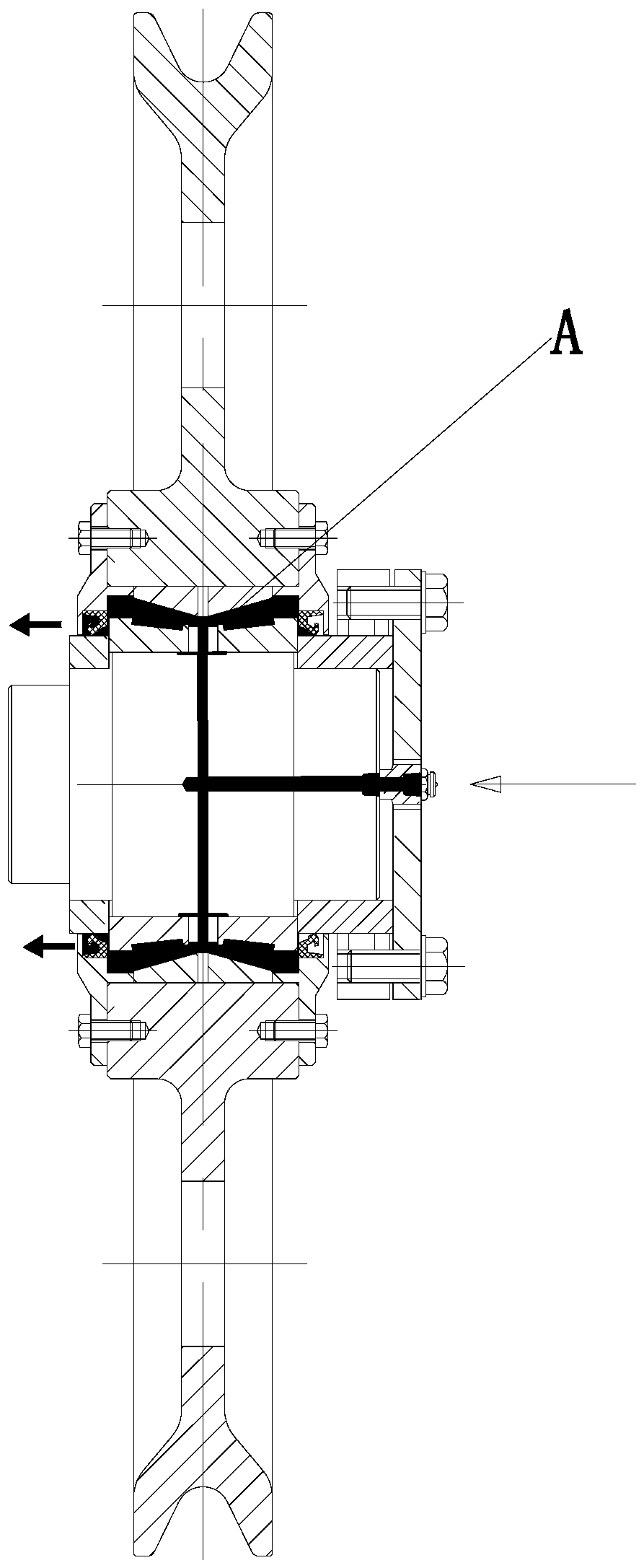

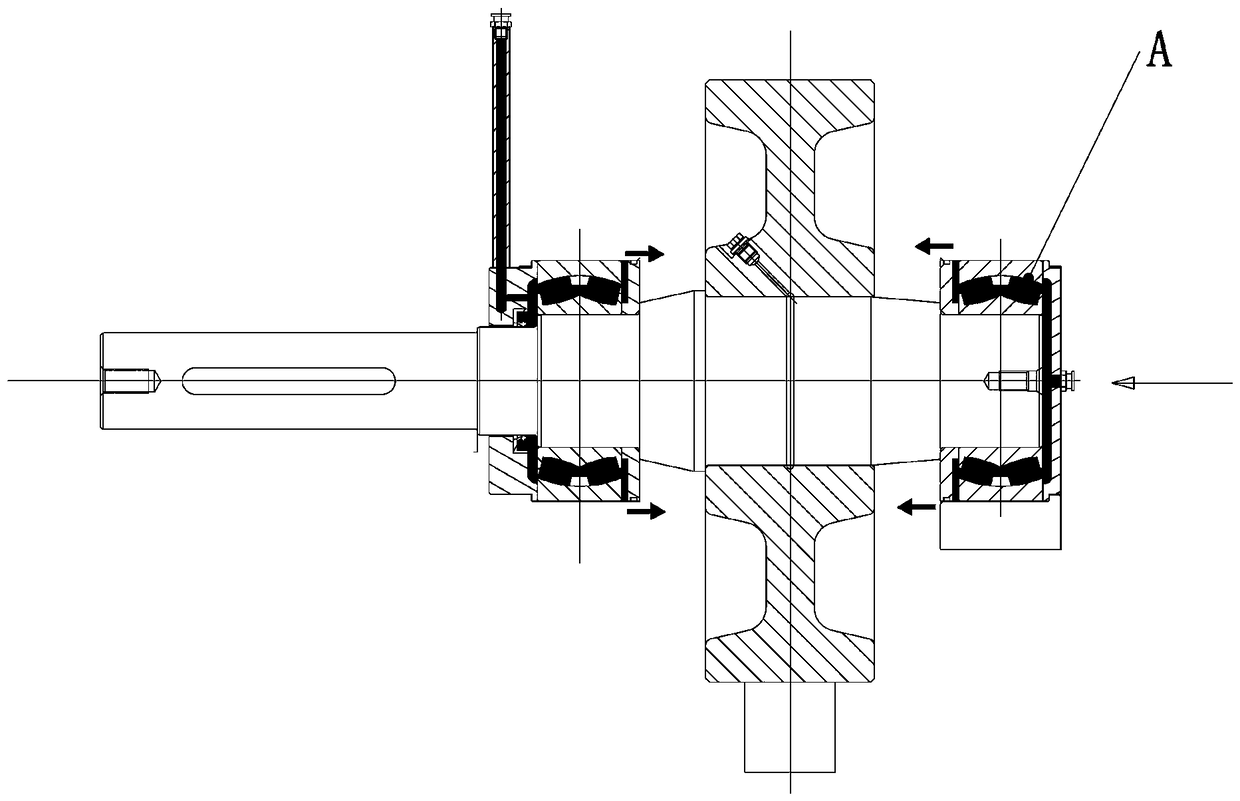

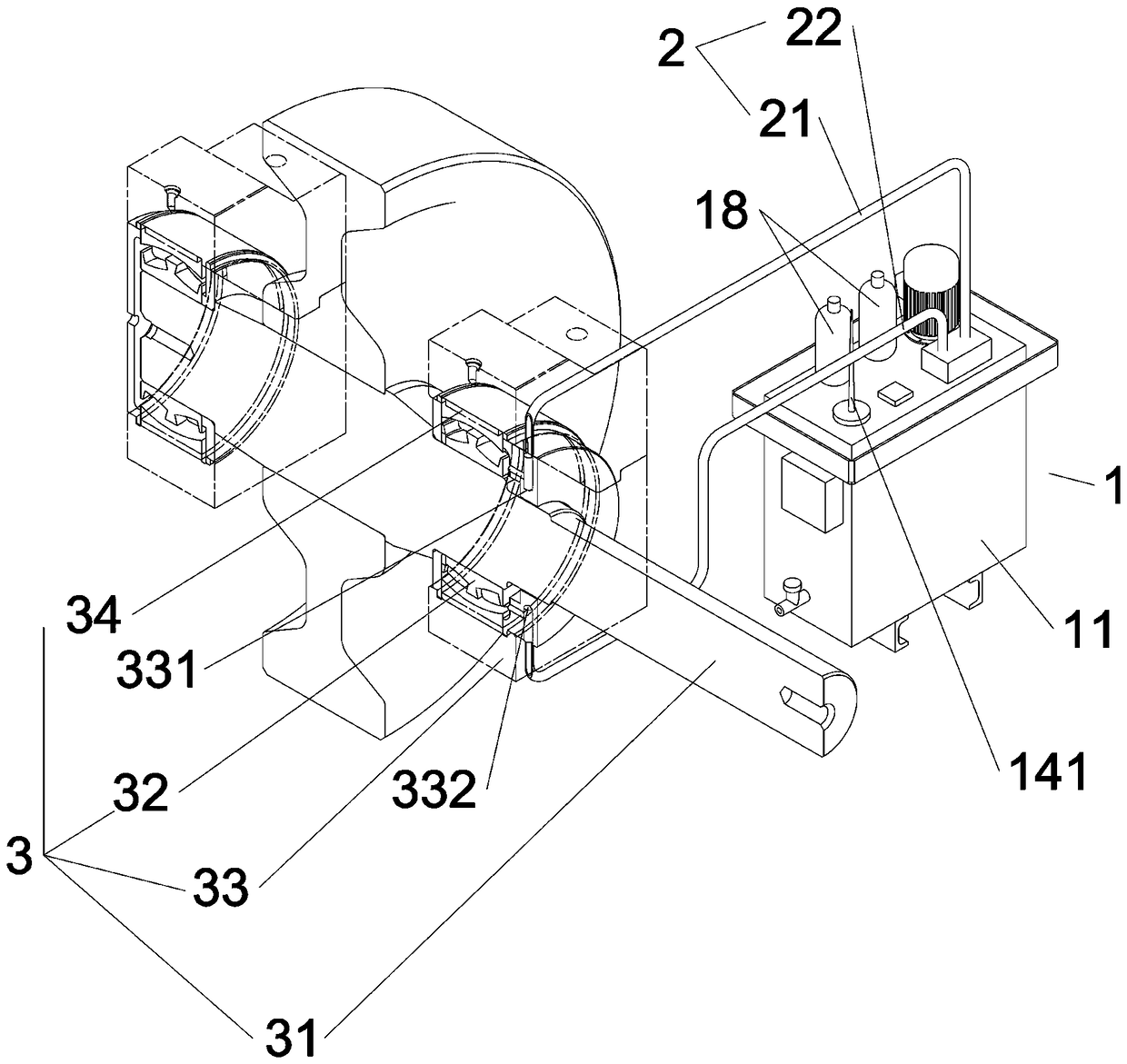

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0036] Figure 3-Figure 11 Shown is an embodiment of the present invention.

[0037] An automatic oil lubrication device for wheel or pulley bearings, comprising a lubrication system hydraulic station 1 and an oil lubrication mechanism 2, the lubrication system hydraulic station 1 is equipped with an oil tank 11, a motor 12, a valve block 13, an oil level and cleanliness detector 14, Output pipe 15, recovery pipe 16; oil lubrication mechanism 2 includes oil inlet pipe 21 and oil return pipe 22 respectively connected to the oil supply place of wheel 3 or pulley 4; wherein, the valve block 13 in the hydraulic station 1 of the lubrication system is connected to the oil tank 11 respectively. The output pipe 15, the recovery pipe 16, and the oil inlet pipe 21 and the oil return pipe 22 in the oil lubrication mechanism 2, the hydraulic oil in the oil tank 11 is sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com