Steel ball cold heading test device

A test device and cold heading technology, applied in the direction of operating device, hammer drive device, forging/pressing/hammer device, etc., can solve problems such as confusion, waste of manpower and material resources, and equipment paralysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

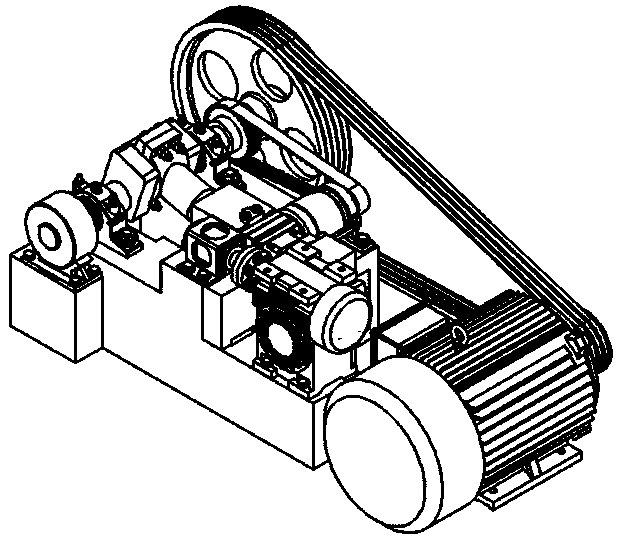

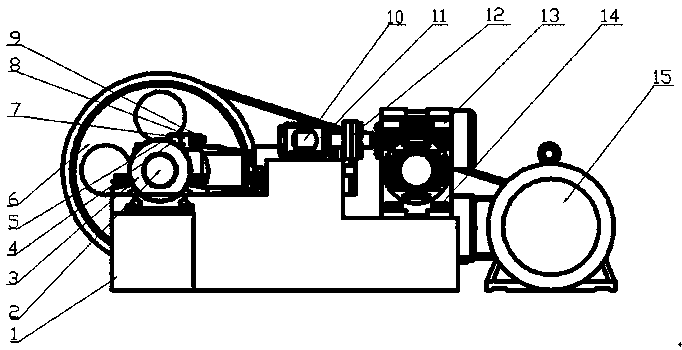

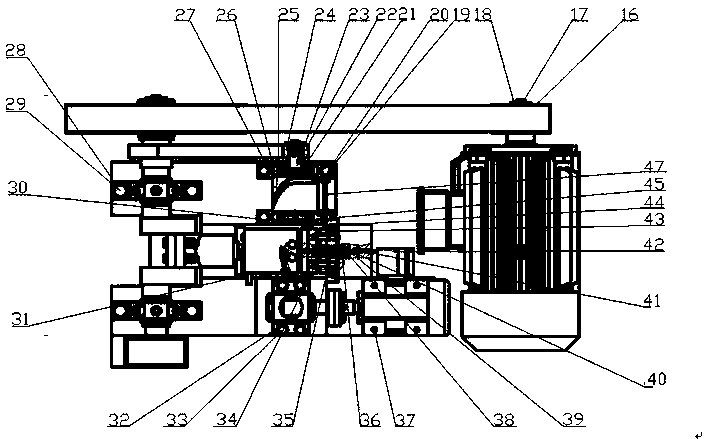

[0015] Such as Figure 1 to Figure 4 As shown, the present invention includes 1 fuselage, 2 magnetic powder brakes, 3 sliding bearings, 4 upper bearing bushes, 5 hex head bolts, 6 large pulleys, 7 slider groups, 8 spring washers, 9 hex nuts, 10 servo motors, 11 Servo motor support, 12 Coupling, 13 Reducer, 14 Hex head bolt, 15 Motor, 16 Small pulley, 17 Set screw, 18 Baffle plate, 19 Roller, 20 Hex head bolt, 21 Sleeve, 22 Cylindrical cam, 23 key, 24 small synchronous pulley, 25 deep groove ball bearing, 26 bearing seat, 27 spring washer, 28 spring washer, 29 hexagon head bolt, 30 hexagon head bolt, 31 linear guide, 32 spring washer, 33 hexagon Head bolt, 34 guide column, 35 mold, 36 sensor, 37 spring washer, 38 ejector rod, 39 spring, 40 spring pressure plate, 41 hex nut, 42 plane cam, 43 cold heading die die, 44 spring washer, 45 Baffle plate, 46 hex head nut, 47 push rod, 48 sleeve, 49 crankshaft, 50 sleeve, 51 key, 52 large synchronous pulley, 53 key, 54 sleeve, 55 synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com