Coal Mine Gas Drainage System and Method for Increasing Gas Drainage Concentration by Variable-diameter Reaming

A technology of gas drainage and coal mine gas, which is applied in the field of coal mine gas drainage system, can solve the problems that materials cannot be taken out for secondary use, the treatment effect has not been achieved, and drilling holes cannot be reused, etc., so as to avoid the increase of cost and realize convenience , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

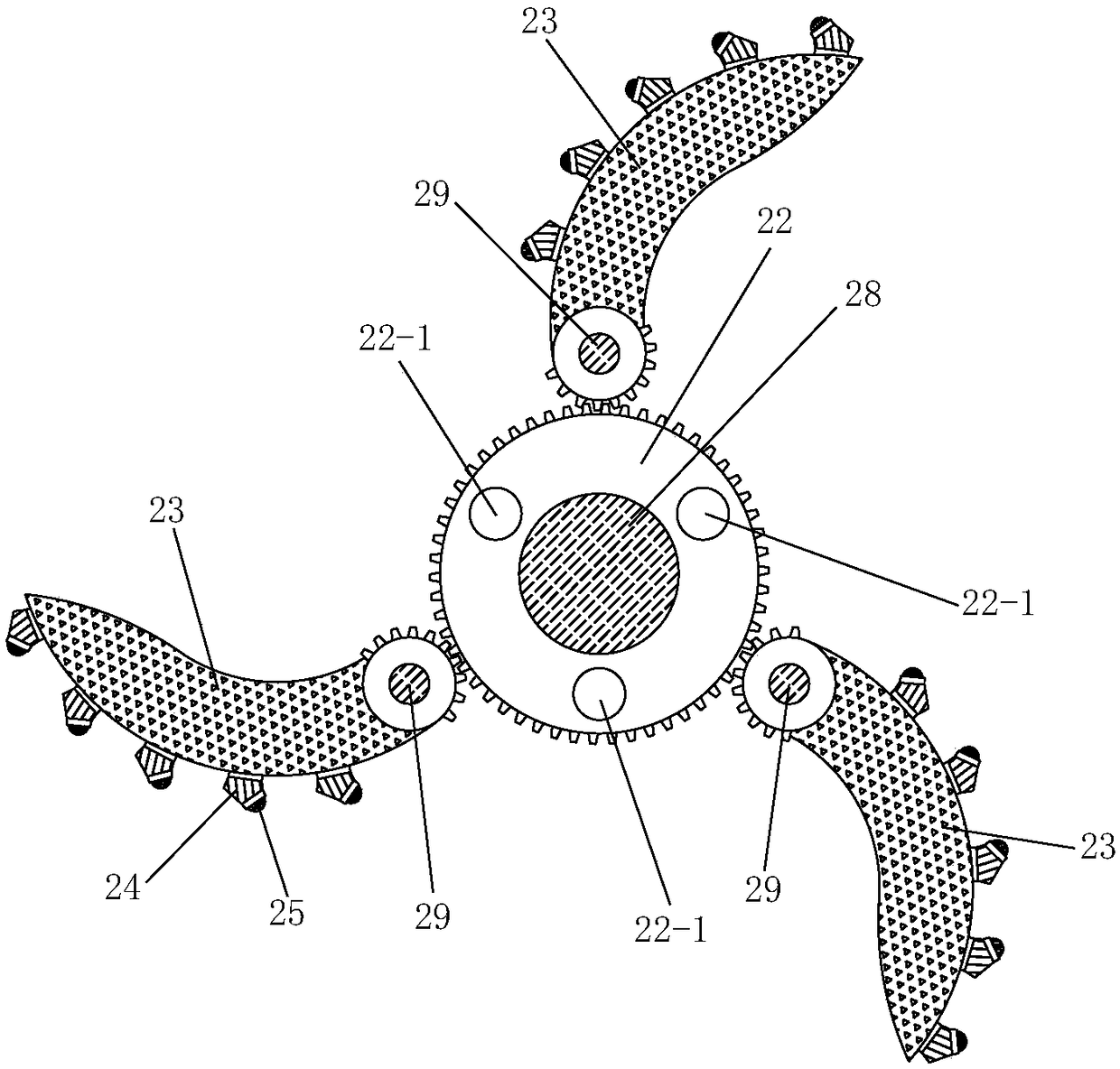

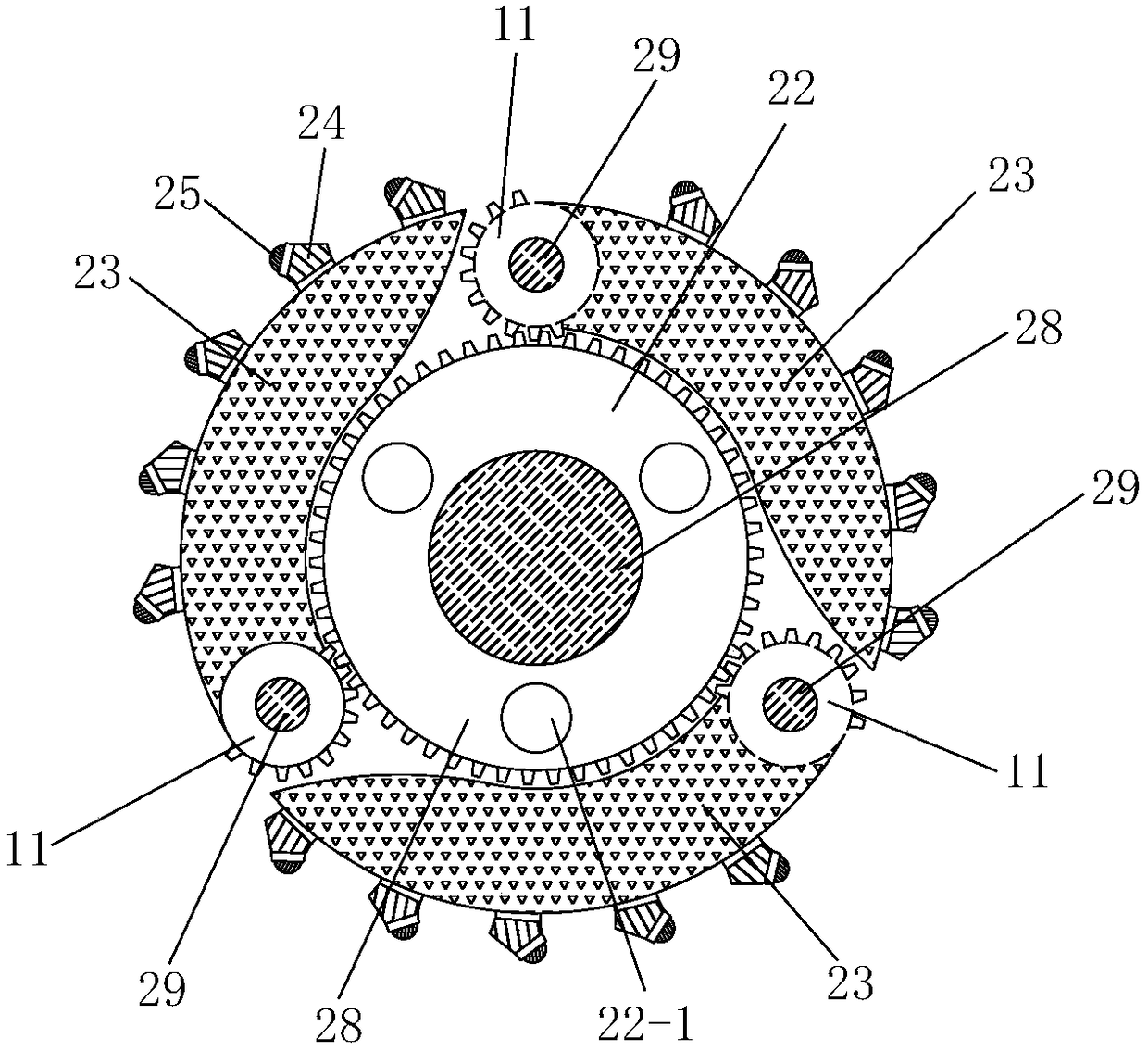

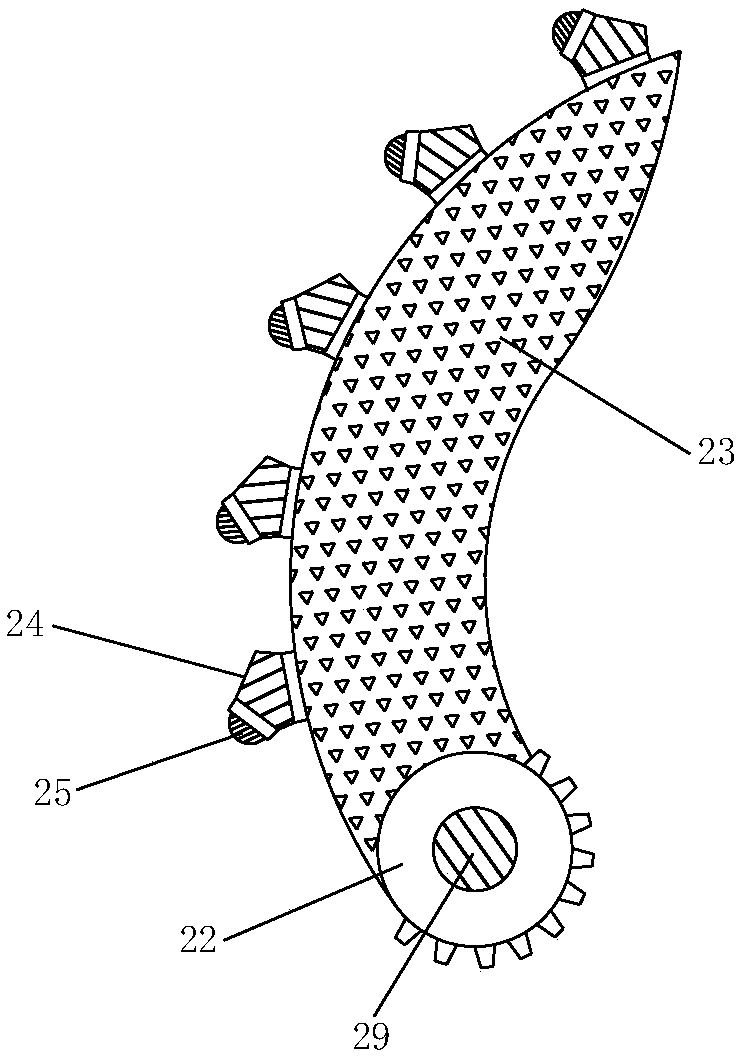

[0054] The coal mine gas drainage system for increasing the concentration of gas drainage with variable diameter reaming of the present invention includes a coal mine drilling rig, a drilling bit, a hole sealing mechanism, a grouting pipeline system and a gas drainage pipeline system; it also includes a reaming drill bit, Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the reaming drill bit includes a power transmission mechanism and a drill blade 23, and the power transmission mechanism includes a sun gear 22 and three planetary gears 11 that are evenly arranged on the periphery of the sun gear 22 and meshed with the sun gear 22. Said sun gear 22 is fixedly connected on the sun gear rotating shaft 28, said planetary gear 11 is rotatably connected on the planetary gear rotating shaft 29, and the quantity of said drill bit vanes 23 is three and three drill bit vanes 23 are connected with three planetary gears respectively. The gear 11 is fixedly connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com