Simple safety valve shield for stand column

A safety valve and shield technology, which is applied to pillars/supports, mining equipment, earth-moving drilling, etc., can solve the problems of affecting the strength of the cylinder block, increase the cost, complex structure, etc., achieve simple structure, convenient installation and disassembly, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

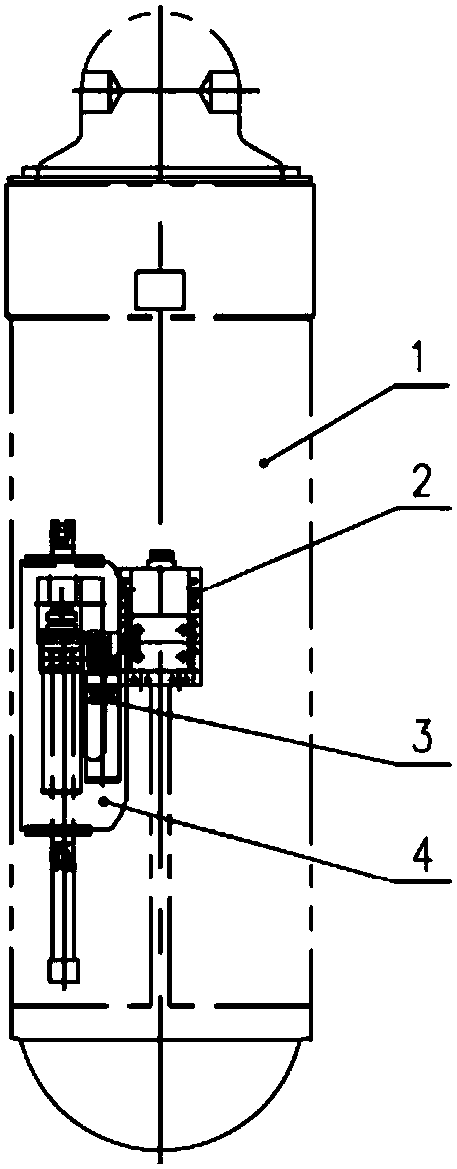

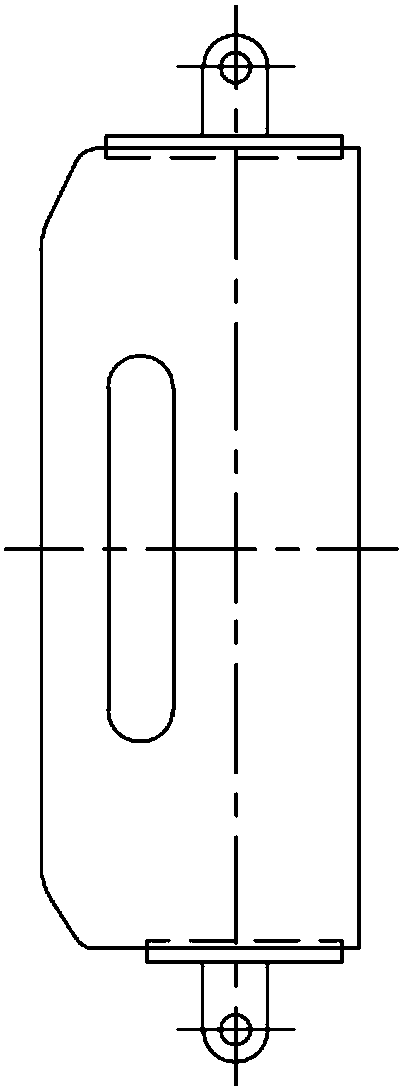

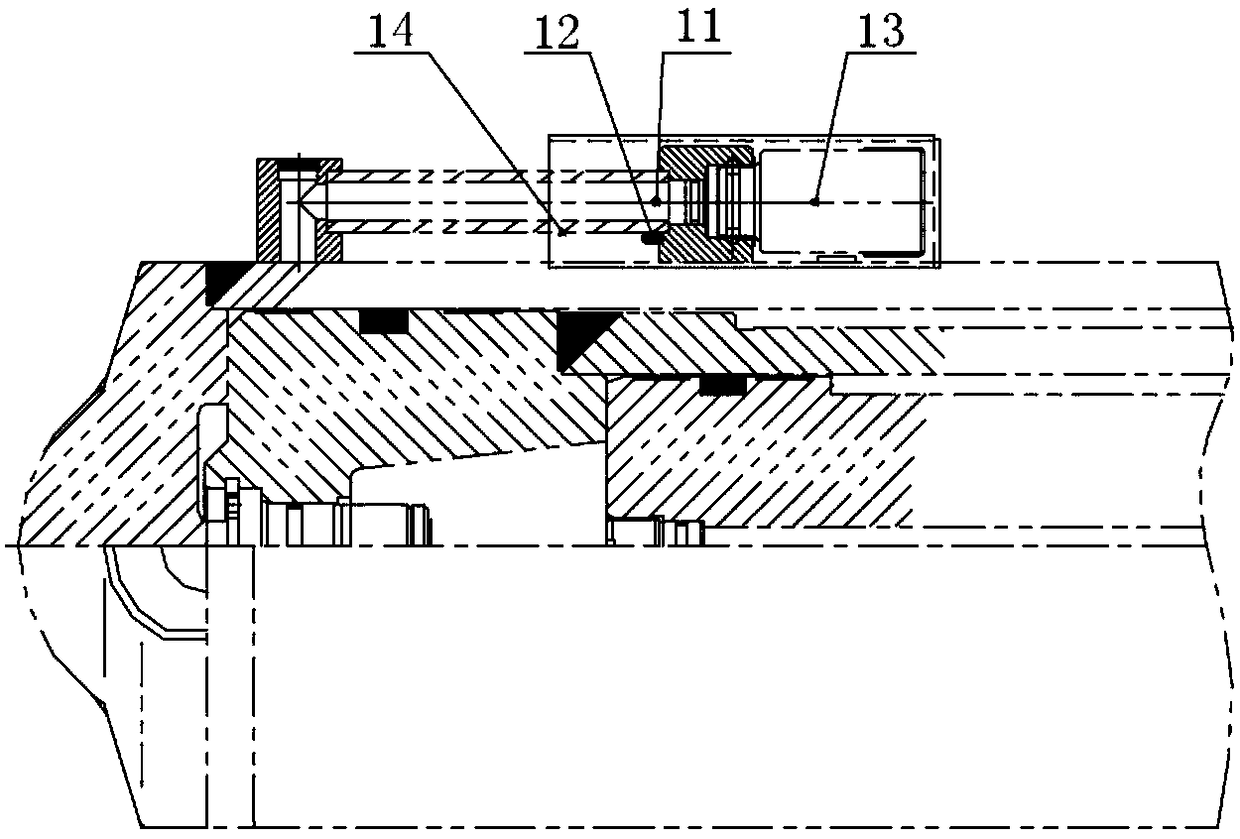

[0023] The preferred embodiment of the simple column safety valve shield of the present invention is:

[0024] The shield consists of a channel structure made of thin-walled steel plates surrounded by three sides and open on one side. The upper end of the channel structure is sealed and the lower end is open. Corresponding small holes are provided on the opposite sides of the channel structure. , There is a fixing piece in the small hole.

[0025] The fixing part is any one of the following: cotter pin, U-shaped card, B-shaped pin, bolt and nut, steel bar, steel bar.

[0026] After the safety valve is installed on the column, buckle the guard cover, and put a fixing piece in the small hole to realize the fixing of the guard cover.

[0027] The fixing part is installed under the valve seat of the safety valve.

[0028] The simple column safety valve shield of the present invention does not need ear plates on the shield, has a simple structure and a smooth shape; only cotter p...

specific Embodiment

[0029] like image 3 , Figure 4 , Figure 5 As shown, the shield of the simple safety valve is made of thin-walled steel plate, and there is no lug plate on the shield, so the structure is simple. Small holes are machined on the guard for passing the cotter pins. After the column safety valve is installed on the column, fasten the safety valve guard and put on the cotter pin to complete the fixing of the guard.

[0030] After the shield is buckled on the safety valve, it is necessary to ensure that the cotter pin hole is under the safety valve seat of the column, so that the cotter pin can play the role of fixing the shield.

[0031] The beneficial effects brought by the technical solution of the present invention:

[0032] The simple safety valve shield has a simple structure and low processing cost;

[0033] There is no need to weld accessories on the column to avoid the influence of welding on the strength of the column;

[0034] The simple guard is easy to install a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com