Method of using barriers to avoid introducing impurities during crystal ingot casting

A technology of barrier and ingot, applied in the field of crystal preparation, can solve the problems of long production time of single furnace, increase of silicon ingot impurities, growth of tail red area, etc., to improve the utilization rate of raw materials, reduce costs and reduce unqualified parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

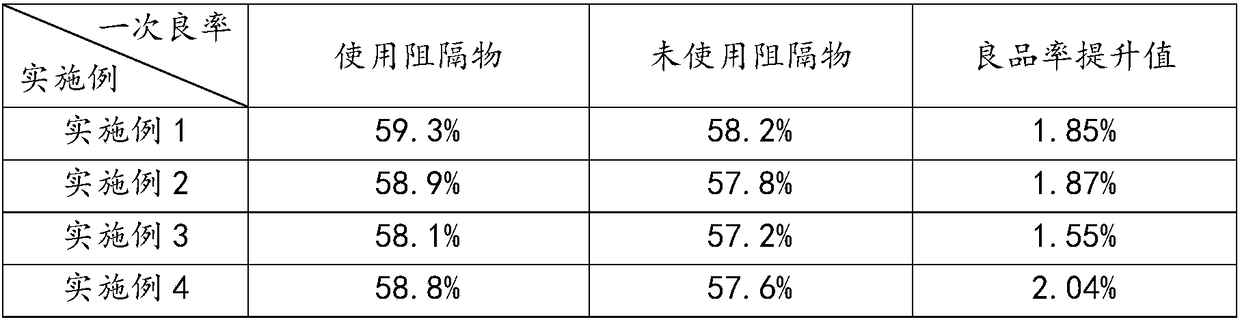

Examples

Embodiment 1

[0033] The method for avoiding the introduction of impurities during the polysilicon ingot casting process by using sorting sheets, the specific steps include the following steps:

[0034] (1) Crucible spray ratio: bottom: 100g silicon nitride + 360ml water, side: 100g silicon nitride + 230ml water + 10ml ceramic binder + 62ml silica sol;

[0035] (2) Bottom laying: put the selected sorting sheet on the bottom of the crucible;

[0036] (3) Seed crystal loading: select a seed crystal with a good crystal orientation and no mechanical damage and load it into the furnace;

[0037] (4) charging: put the silicon material whose purity meets the requirements into the crucible;

[0038] (5) Vacuuming: vacuumize the inside of the crucible, and feed argon;

[0039] (6) Ingot casting: heat the crucible to melt the silicon material, continue heating, and perform semi-melting ingot casting to obtain polysilicon products.

[0040] The length of the red area of the polysilicon product ob...

Embodiment 2

[0042] The method for using silicon wafers to avoid introducing impurities in the process of casting monocrystalline silicon ingots, the specific steps include the following steps:

[0043] (1) Crucible spray ratio: bottom: 100g silicon nitride + 360ml water, side: 100g silicon nitride + 230ml water + 10ml ceramic binder + 62ml silica sol;

[0044](2) Bottom laying: lay the selected silicon wafers on the bottom of the crucible;

[0045] (3) Seed crystal loading: select a seed crystal with a good crystal orientation and no mechanical damage and load it into the furnace;

[0046] (4) charging: the polysilicon with the purity meeting the requirements is loaded into the crucible;

[0047] (5) Vacuuming: vacuumize the inside of the crucible, and feed argon;

[0048] (6) Ingot casting: Heating the crucible to melt the polysilicon, continuing heating, performing semi-melting ingot casting, and obtaining monocrystalline silicon products.

[0049] The length of the red zone of the m...

Embodiment 3

[0051] The method for avoiding the introduction of impurities during the polycrystalline silicon carbide ingot casting process by using sorting sheets, the specific steps include the following steps:

[0052] (1) Crucible spray ratio: bottom: 100g silicon nitride + 360ml water, side: 100g silicon nitride + 230ml water + 10ml ceramic binder + 62ml silica sol;

[0053] (2) Bottom laying: put the selected sorting sheet on the bottom of the crucible;

[0054] (3) Seed crystal loading: select a seed crystal with a good crystal orientation and no mechanical damage and load it into the furnace;

[0055] (4) charging: put the silicon carbide raw material whose purity meets the requirements into the crucible;

[0056] (5) Vacuuming: vacuumize the inside of the crucible, and feed argon;

[0057] (6) Ingot casting: heat the crucible to melt the silicon carbide raw material, continue heating, and perform semi-melting ingot casting to obtain polycrystalline silicon carbide products.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com