Diesel fork lift truck parking safety control method

A safety control technology for internal combustion forklifts, applied to control devices, lifting devices, etc., can solve problems such as brake system wear and tear, brake system damage, fire, etc., to improve safety, prolong life, and reduce slopes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

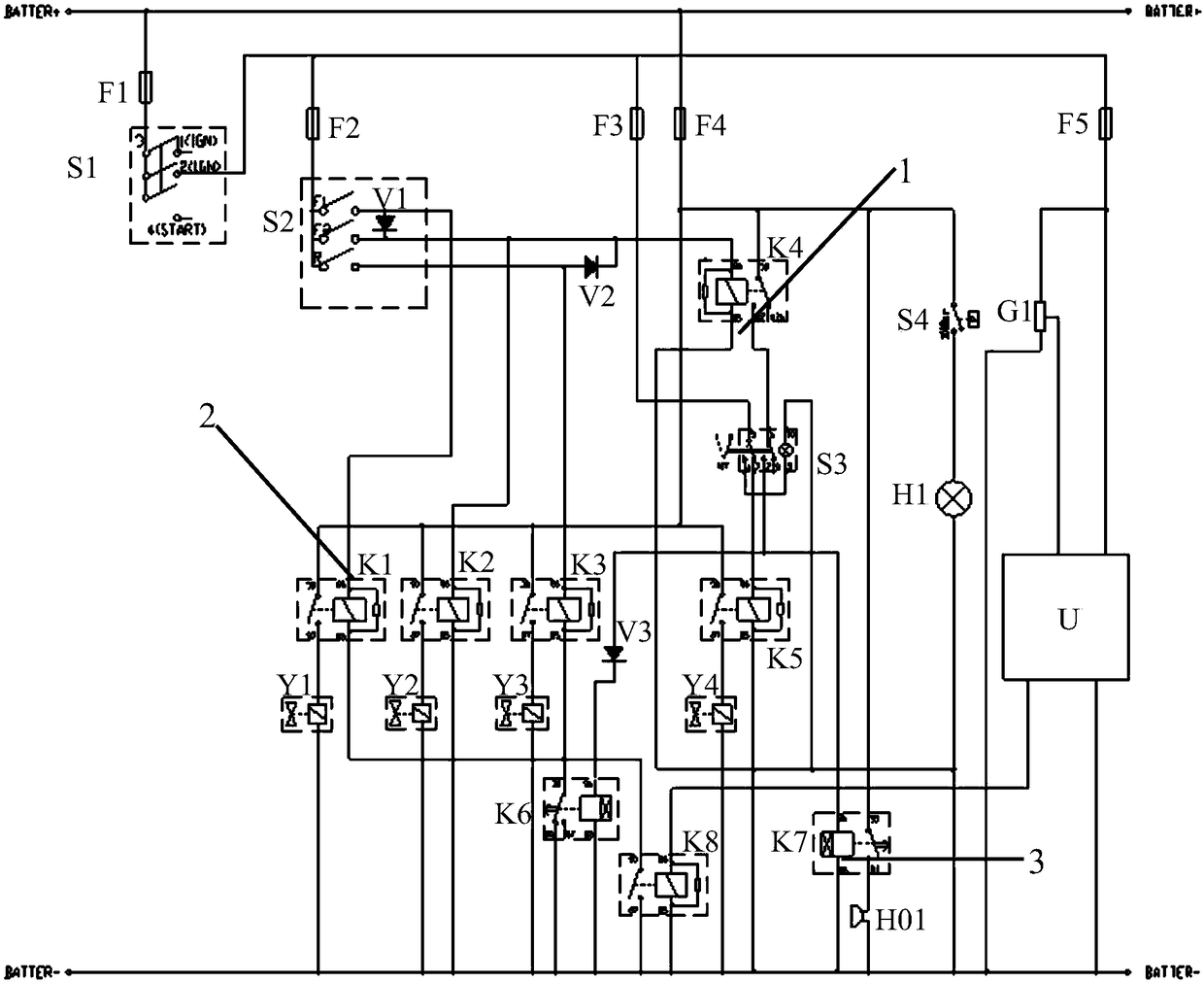

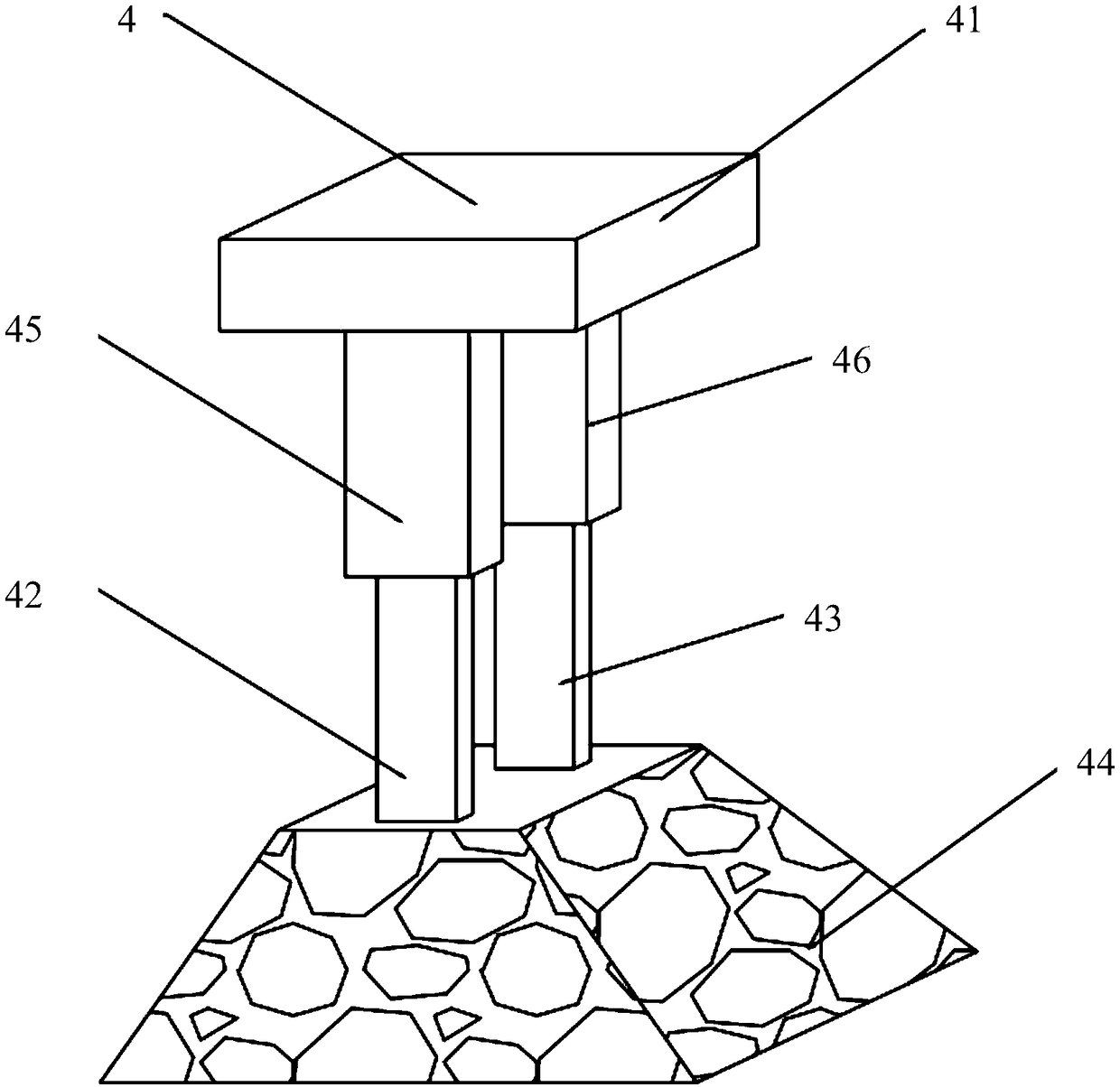

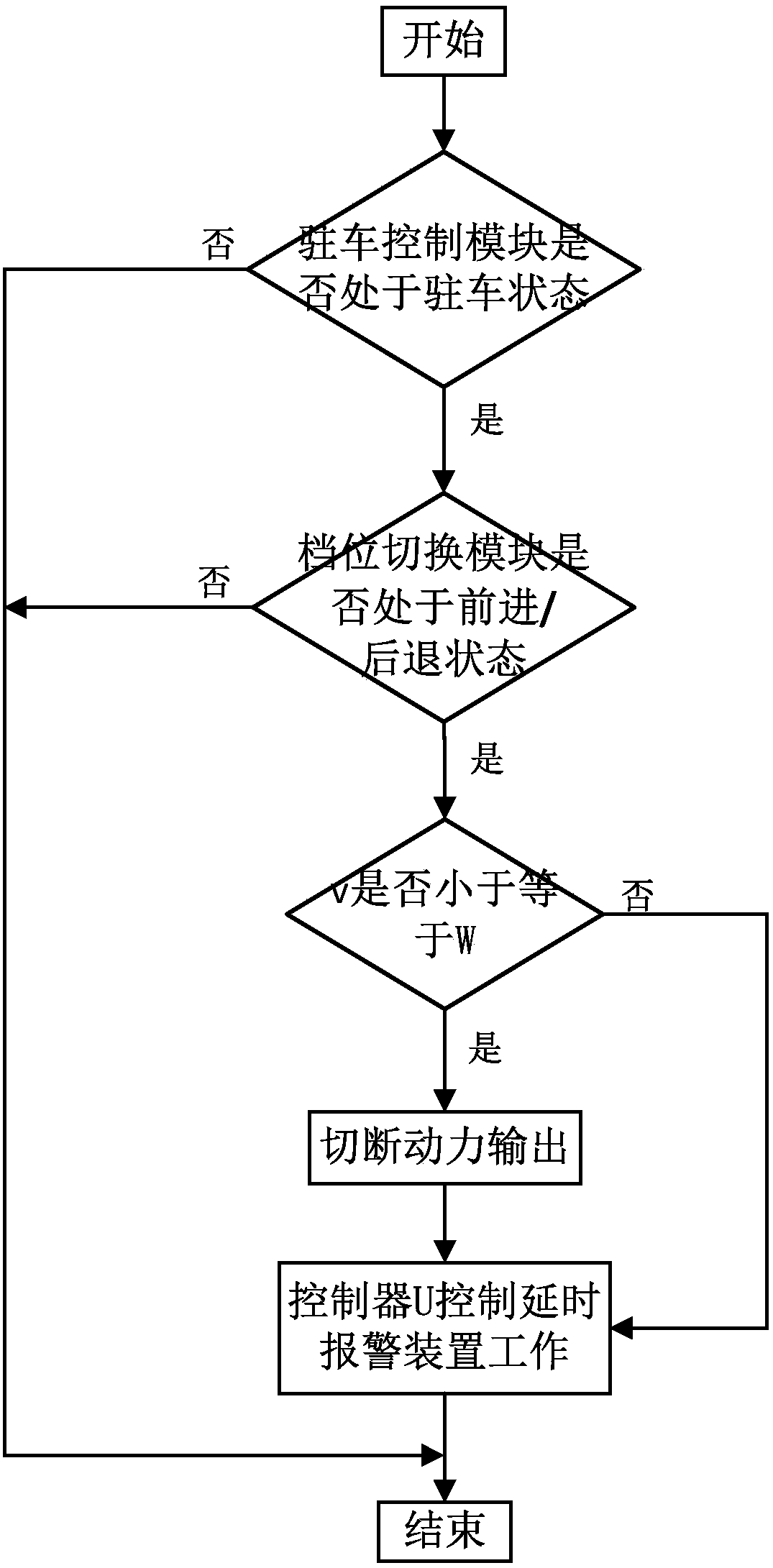

[0023] Such as figure 1 The illustrated embodiment is a parking safety control method for an internal combustion forklift, including a controller U, an angle sensor G1, a parking control module 1, a gear switching module 2, a warm-up start switch S1, a delay alarm device 3, a power Holding relay K8 and anti-slip device 4; controller U is electrically connected with angle sensor G1, preheating start switch S1, power holding relay K8 and anti-slipping device respectively, and preheating start switch S1 is respectively connected with angle sensor G1 and parking control module , the gear switching module, the delay alarm device and the power hold relay K8 are electrically connected, the parking control module is electrically connected with the gear switch module and the delay alarm device respectively, and the gear switch module is respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com