Tooth surface reversing anti-shake control method for electric vehicle

A technology of electric vehicles and control methods, applied to electric vehicles, control drives, control devices, etc., to achieve smooth tooth surface reversing, prevent gear damage, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

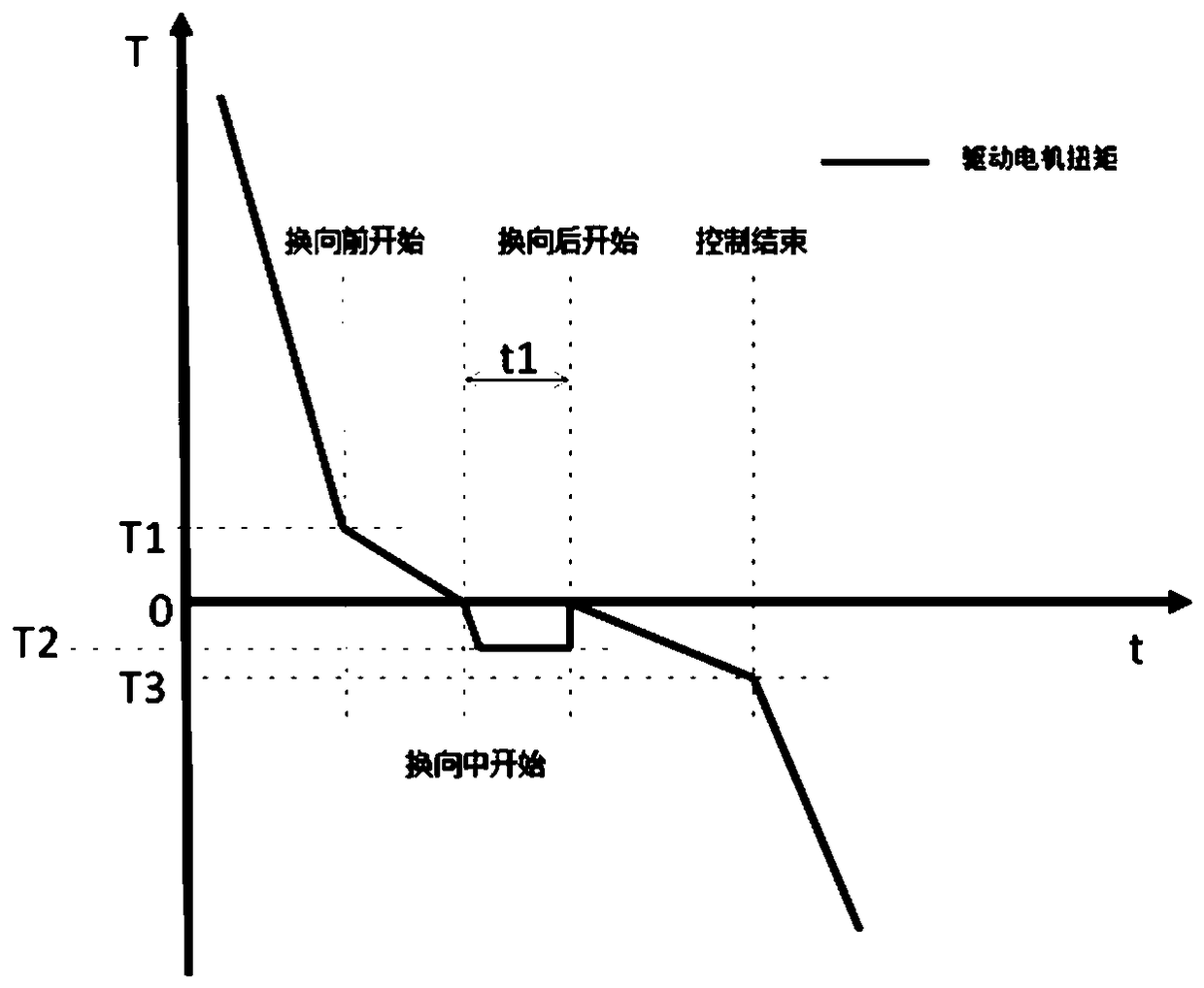

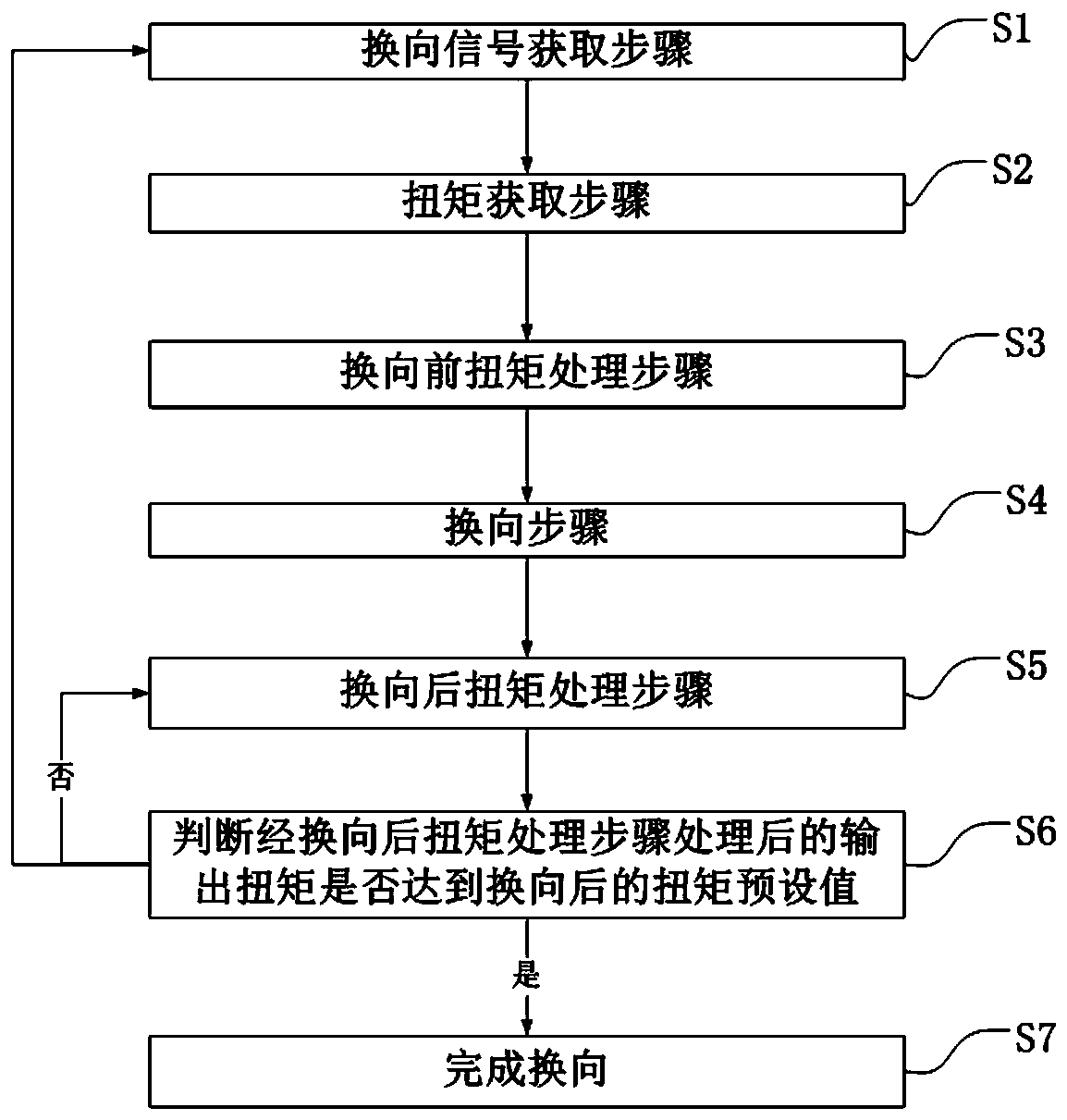

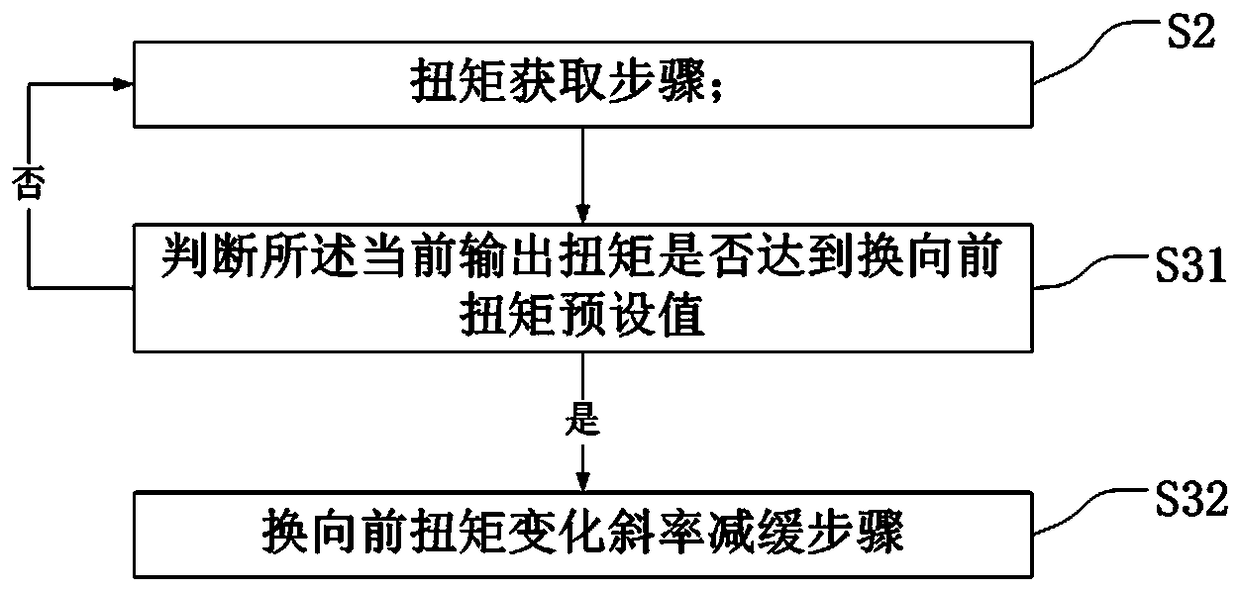

[0020] Examples such as figure 1 As shown, a method for anti-vibration control of tooth surfaces of electric vehicles is applied to electric vehicles. To realize this method, the drive motor, gear pair, accelerator pedal, and vehicle controller in the electric vehicle are required. Wherein, the specific structure and connection relationship of the driving motor, the gear pair, the accelerator pedal, and the vehicle controller are all existing technologies, and will not be repeated here. The tooth surface reversing anti-vibration control method disclosed in this embodiment is aimed at the reversing control during driving, including: when the vehicle controller judges that the vehicle needs to switch from driving mode to energy recovery or from energy recovery to driving mode , start the tooth surface commutation control: firstly, before the tooth surface commutation, reduce the torque conversion slope until the torque is zero; then in the commutation, send out a small reverse z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com