Synchronous mold-opening mechanism

A technology of female mold and male mold, applied in the field of synchronous mold opening mechanism, can solve the problems of difficulty in ensuring synchronous mold opening of male and female molds, difficulty in ensuring synchronous mold opening, and high cost, so as to ensure injection molding quality, low overall manufacturing cost, and high cost. good synchronization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

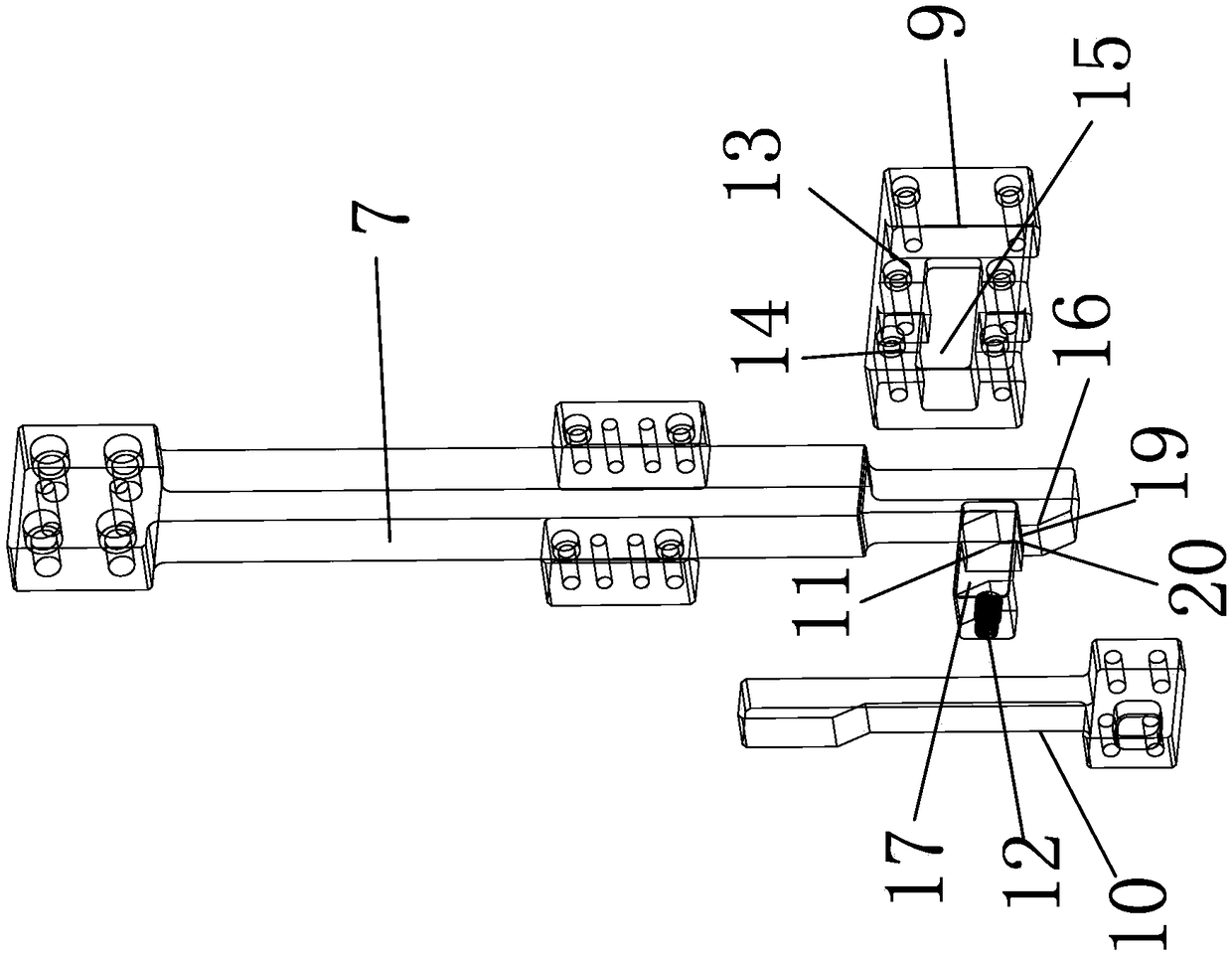

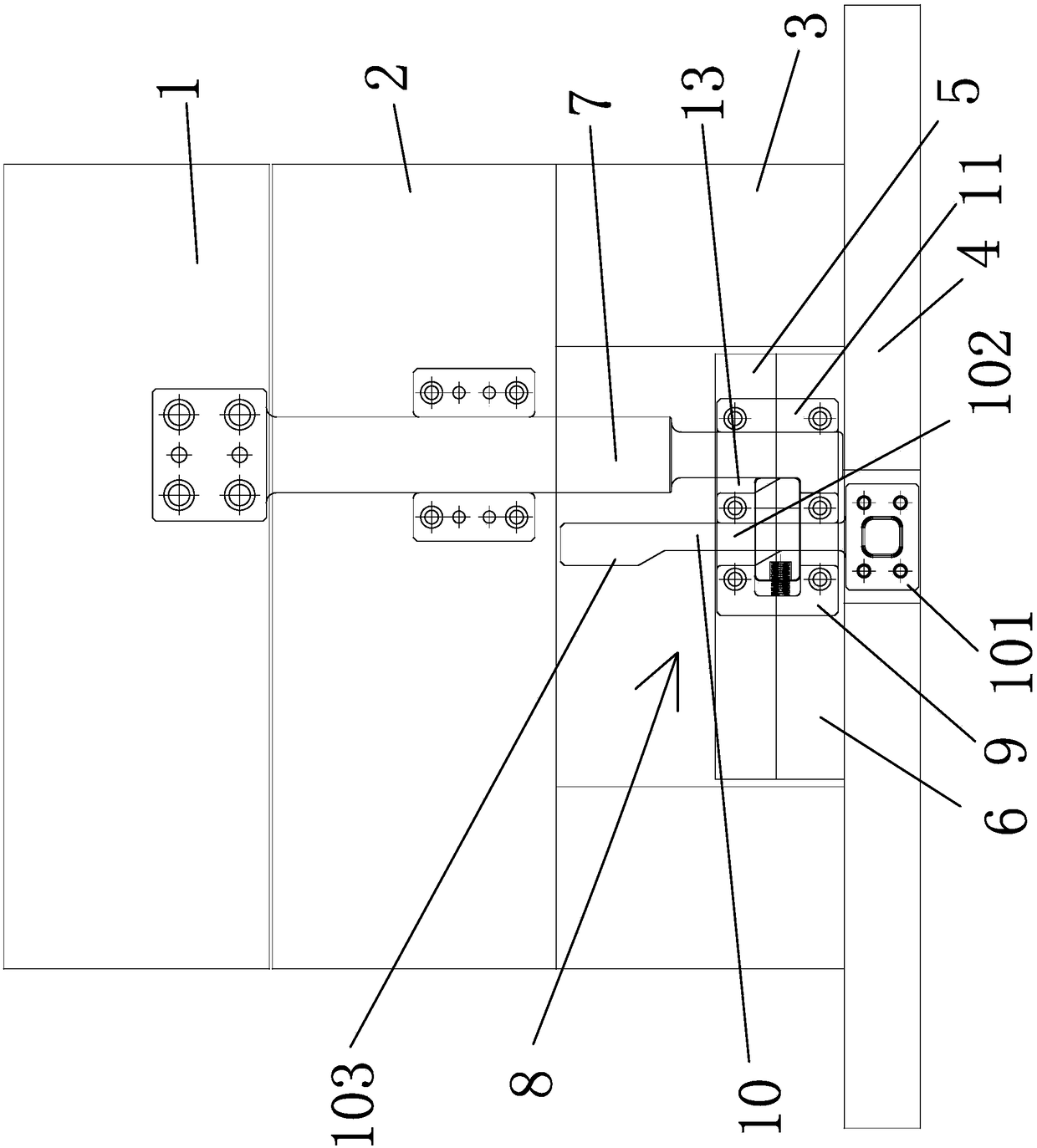

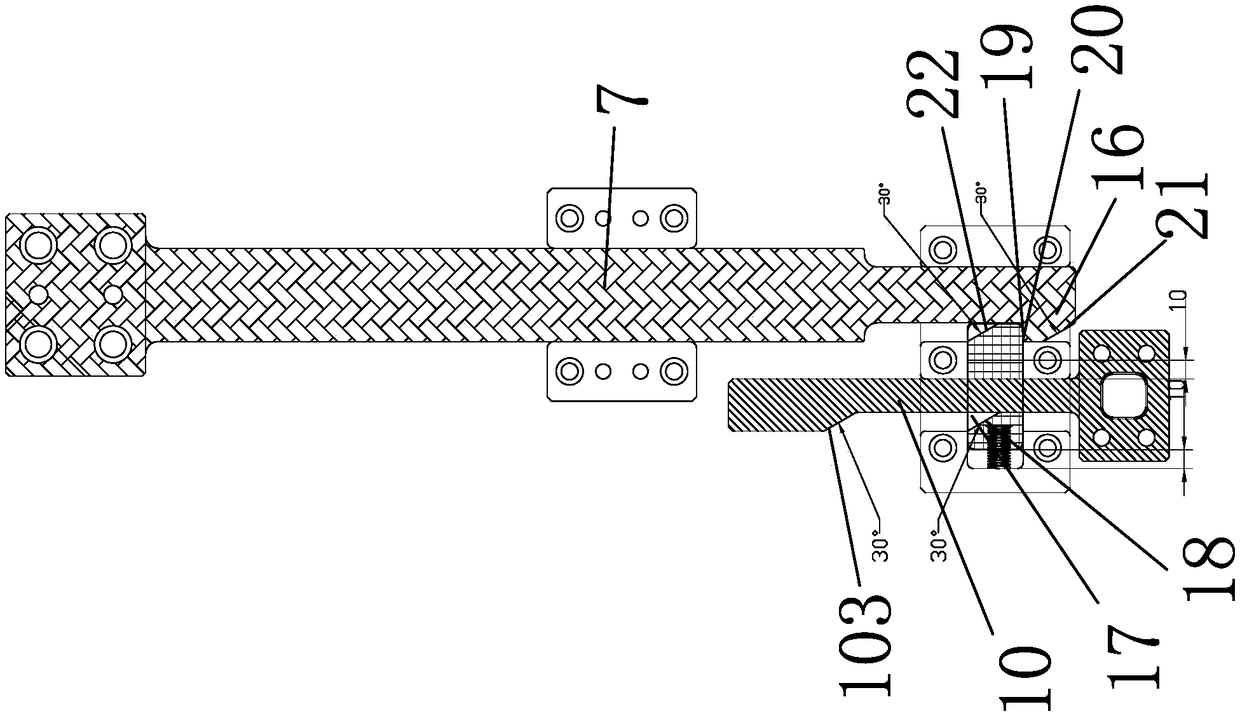

[0017] In the figure, female mold 1; male mold 2; mold foot 3; lower fixed plate 4; upper ejector plate 5; lower ejector plate 6; hook piece 7; mechanical synchronous mold opening device 8; locking seat 9; lever 10 ; the lower fixed part 101; the main part of the lever 102; the tilted head 103; the sliding block 11; the load spring 12; the hook groove 13; 18 ; the retaining surface of the hook head 19 ; the abutment surface 20 ; the oblique insertion part 21 of the hook head;

[0018] like figure 1 and figure 2 As shown, the synchronous mold opening mechanism includes a female mold 1, a male mold 2, a mold foot 3, an ejector plate assembly and a lower fixing plate 4 from top to bottom, and the ejector plate assembly is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com