Spraying maintaining device and system

A sprinkler and track technology, applied in the field of concrete maintenance, can solve the problems of excessive labor consumption, inconvenient concrete maintenance, and poor maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

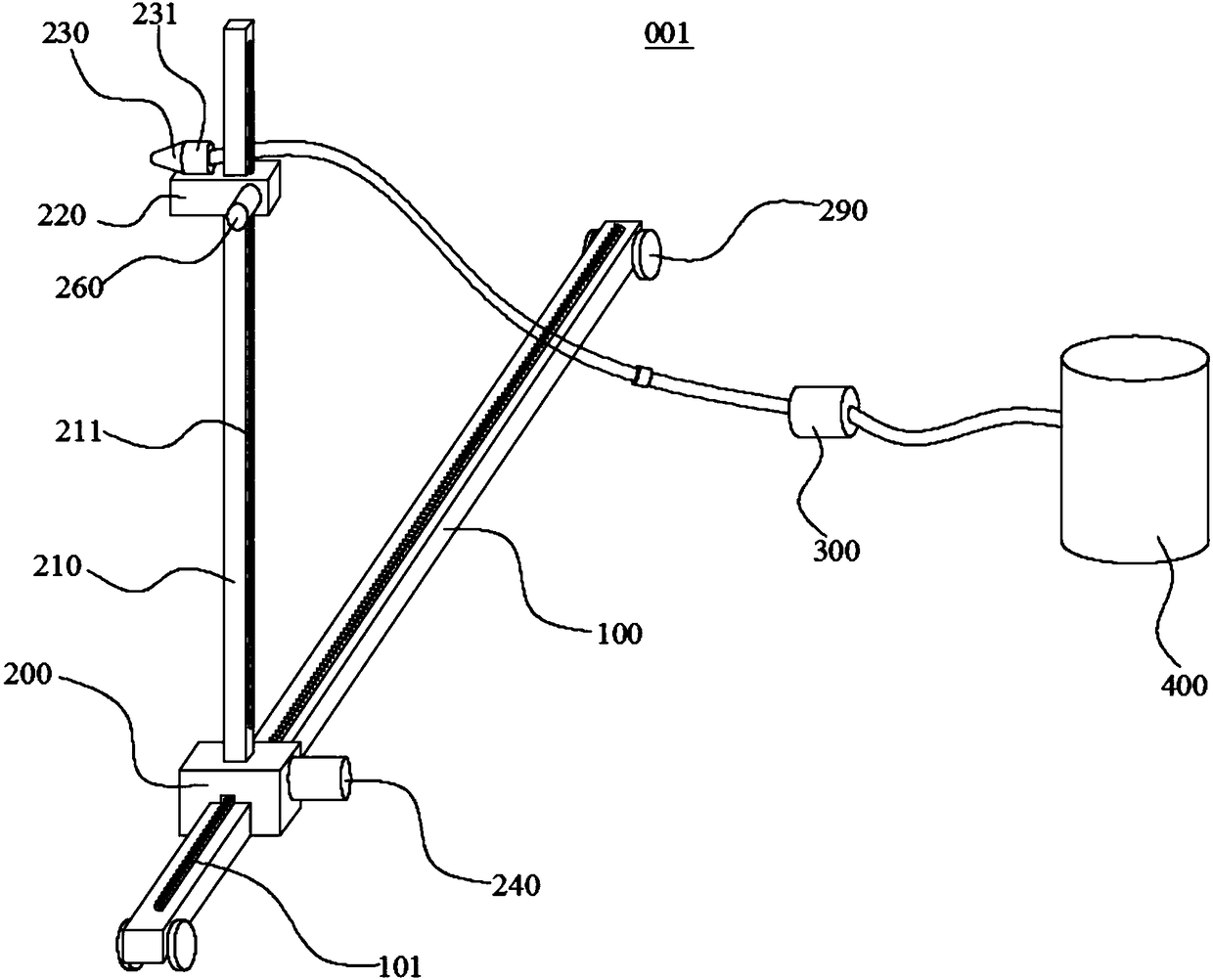

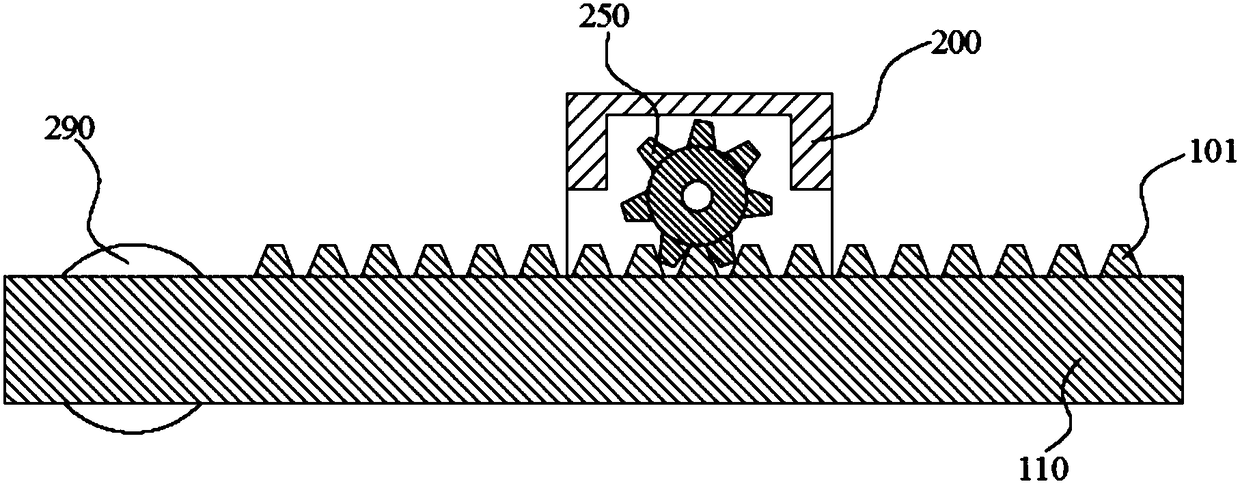

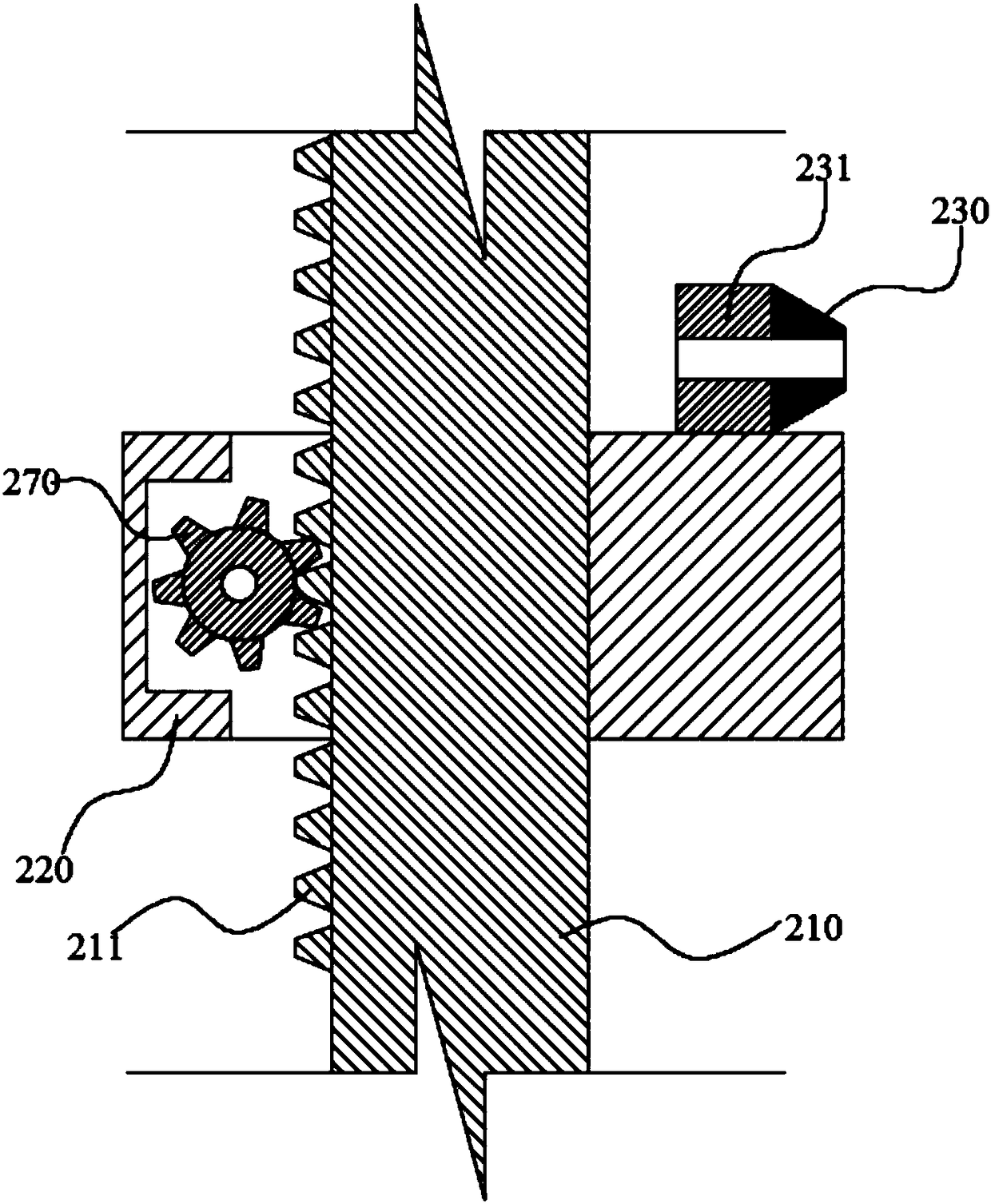

[0033] Please refer to figure 1 , figure 2 , image 3 As shown, the present embodiment provides a spray maintenance device 001, which includes a track 100 and at least one base 200 that can move along the track 100, each base 200 is connected with a pole 210, and the pole 210 is provided with There is at least one shower seat 220 movable along it. The shower seat 220 is connected with at least one shower head 230 , and the shower head 230 is connected with a water tank 400 through a water pump 300 . In this embodiment, a base 200 that can move along the track 100 is provided, and a spray seat 220 is provided on the pole 210 connected to the base 200. The pole 210 is arranged vertically, and the water pump 300 passes through the water pipe. A hollow fixing seat 231 is connected, and the fixing seat 231 is connected with the shower head 230 .

[0034] The spray maintenance device 001 provided by the embodiment of the present invention can perform automatic and stable spray m...

Embodiment 2

[0040] Please refer to figure 2 , image 3 , Figure 4 and Figure 5 As shown, this embodiment provides a spray maintenance system 002, which includes a spray maintenance device, and the spray maintenance device includes a track 100, two bases 200 that can move along the track 100, two water pumps 300 and a water tank 400 , each base 200 is connected with a pole 210, and each pole 210 is respectively provided with two spray seats 220 movable along it, and each spray seat 220 is connected with two spray heads 230, The shower heads 230 provided on each base 200 are connected to the water tank 400 through a water pump 300, and the projection angle of the spray direction of the adjacent shower heads 230 on the shower seat 220 on the horizontal plane is 45 degrees, each The shower head 230 on the base 200 is connected to the water pump 300 through a water pipe with a flow valve, and each water pump 300 is connected to a hollow fixed seat 231 provided on the spray seat 220 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com